Yield strength defines the maximum stress a material can withstand without permanent deformation, crucial for engineering and structural applications. Understanding yield strength helps you select appropriate materials to ensure safety and performance under load. Explore the full article to learn how yield strength impacts material selection and design.

Table of Comparison

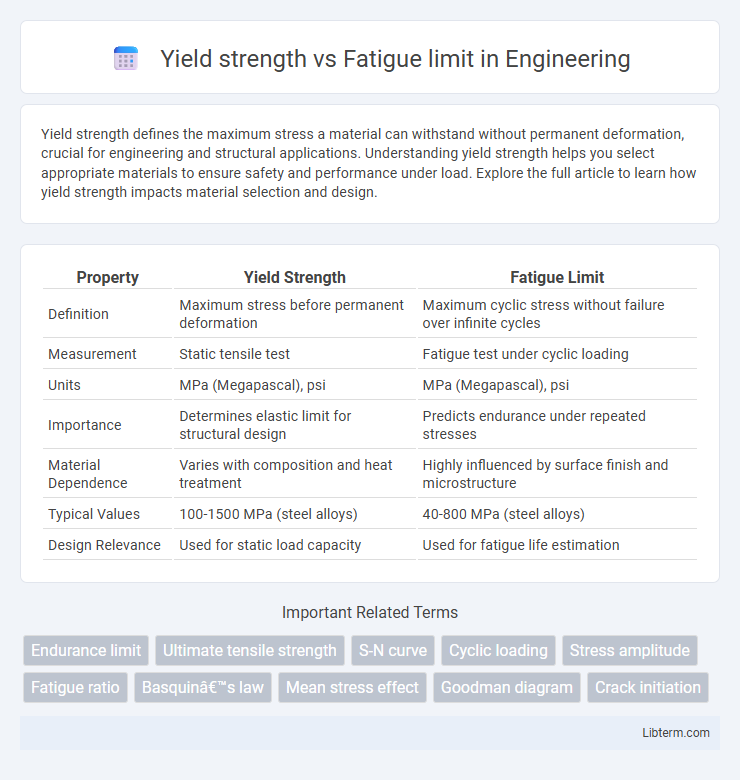

| Property | Yield Strength | Fatigue Limit |

|---|---|---|

| Definition | Maximum stress before permanent deformation | Maximum cyclic stress without failure over infinite cycles |

| Measurement | Static tensile test | Fatigue test under cyclic loading |

| Units | MPa (Megapascal), psi | MPa (Megapascal), psi |

| Importance | Determines elastic limit for structural design | Predicts endurance under repeated stresses |

| Material Dependence | Varies with composition and heat treatment | Highly influenced by surface finish and microstructure |

| Typical Values | 100-1500 MPa (steel alloys) | 40-800 MPa (steel alloys) |

| Design Relevance | Used for static load capacity | Used for fatigue life estimation |

Introduction to Yield Strength and Fatigue Limit

Yield strength represents the maximum stress a material can endure without undergoing permanent deformation, serving as a critical parameter in static load conditions. Fatigue limit defines the highest stress amplitude a material can withstand indefinitely without failure under cyclic loading, crucial for components subject to repeated stress. Understanding both yield strength and fatigue limit is essential for designing durable structures that resist permanent deformation and fatigue failure.

Defining Yield Strength

Yield strength defines the maximum stress a material can withstand without permanent deformation, marking the transition from elastic to plastic behavior in metals and alloys. It is fundamental for engineering designs to ensure components maintain structural integrity under static loads. Unlike fatigue limit, which indicates the stress threshold below which a material can endure infinite cyclic loading, yield strength governs the initial stress-bearing capacity before any permanent change occurs.

Understanding Fatigue Limit

Yield strength measures the maximum stress a material can withstand without permanent deformation, whereas the fatigue limit defines the stress threshold below which a material can endure an infinite number of loading cycles without failure. Understanding fatigue limit is critical in designing components subject to repeated or cyclic loading, as it predicts the material's durability and longevity under fluctuating stresses. Materials like steel exhibit a distinct fatigue limit, enabling engineers to ensure safety and performance in applications such as bridges and aircraft structures.

Key Differences Between Yield Strength and Fatigue Limit

Yield strength represents the maximum stress a material can endure without permanent deformation, while fatigue limit indicates the stress level below which a material can withstand an infinite number of loading cycles without failure. Yield strength is a static property measured during a single application of load, commonly evaluated through tensile testing, whereas fatigue limit is dynamic, determined through cyclic loading tests over extended periods. Understanding these distinctions is crucial for designing components subjected to both immediate loads and repetitive stress, ensuring long-term structural integrity and performance.

Factors Affecting Yield Strength

Yield strength is influenced by factors such as material composition, heat treatment, grain size, and strain rate, which determine how a material deforms under stress before permanent deformation occurs. Fatigue limit, on the other hand, depends largely on cyclic loading conditions, surface finish, and environmental factors like corrosion, impacting the material's resistance to crack initiation under repeated stress. Understanding the interplay between microstructure modifications and loading environments is critical for optimizing yield strength and fatigue performance in engineering applications.

Factors Influencing Fatigue Limit

Yield strength defines the maximum stress a material can withstand without permanent deformation, while fatigue limit represents the stress threshold below which a material can endure infinite cyclic loading without failure. Factors influencing fatigue limit include surface finish, where smoother surfaces reduce stress concentrators, material composition and microstructure that dictate crack initiation resistance, and operational environment such as temperature and corrosive exposure accelerating fatigue damage. Stress concentration factors from geometric discontinuities, residual stresses from manufacturing processes, and load frequency also critically affect the fatigue limit, determining a material's durability under repeated stress cycles.

Testing Methods for Yield Strength and Fatigue Limit

Yield strength testing primarily utilizes tensile tests, where a specimen is subjected to increasing uniaxial stress until permanent deformation occurs, measured by stress-strain curves following standards such as ASTM E8. Fatigue limit testing employs rotating bending or axial fatigue tests, exposing samples to cyclic loading to determine the maximum stress amplitude that avoids failure after a specified number of cycles, guided by protocols like ASTM E466. Accurate assessment of both properties involves precise control of load, frequency, and environmental conditions to ensure reliable material performance predictions under static and cyclic stresses.

Importance in Material Selection and Design

Yield strength determines the maximum stress a material can withstand without permanent deformation, crucial for ensuring structural integrity under static loads. Fatigue limit defines the stress threshold below which a material can endure infinite cyclic loading without failure, essential for components subjected to repetitive stresses. Prioritizing both properties in material selection and design ensures durability and safety in applications ranging from aerospace to automotive engineering.

Real-World Applications and Case Studies

Yield strength determines the maximum stress a material can withstand before permanent deformation, critical for structural components under static loads like building frameworks and pressure vessels. Fatigue limit indicates the stress threshold below which a material can endure infinite load cycles without failure, essential in rotating machinery, aircraft wings, and bridge cables subjected to repetitive stress. Case studies in aerospace engineering highlight that designs prioritizing fatigue limit over yield strength prevent catastrophic failures from cyclic loading, enhancing safety and durability.

Conclusion: Choosing the Right Property for Engineering Needs

Yield strength defines the maximum stress a material withstands before permanent deformation, while fatigue limit indicates the stress threshold below which a material can endure infinite loading cycles without failure. Selecting the appropriate property depends on the specific engineering application: yield strength is critical for static or impact loads, whereas fatigue limit governs performance under cyclic or fluctuating stresses. Engineers must evaluate operating conditions and loading patterns to ensure structural integrity and longevity by prioritizing the relevant mechanical property.

Yield strength Infographic

libterm.com

libterm.com