Extrusion is a versatile manufacturing process that involves shaping material by forcing it through a die to create objects with a fixed cross-sectional profile. This technique is widely used in industries such as plastics, metals, and food production to produce pipes, sheets, and various complex shapes efficiently. Discover how extrusion can optimize Your production capabilities by exploring the rest of this article.

Table of Comparison

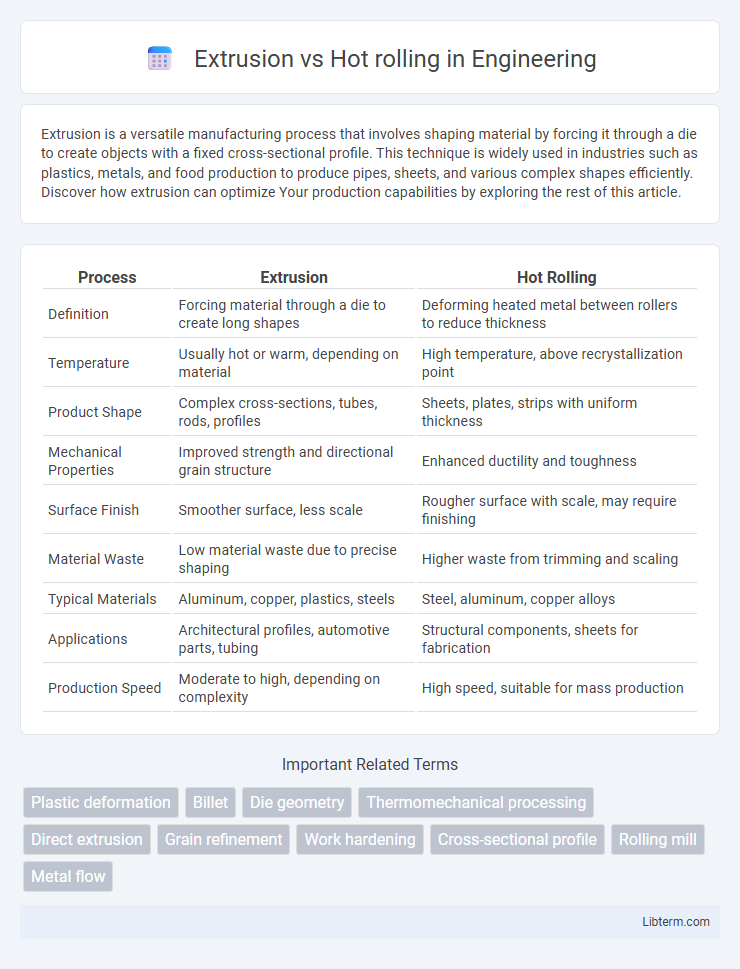

| Process | Extrusion | Hot Rolling |

|---|---|---|

| Definition | Forcing material through a die to create long shapes | Deforming heated metal between rollers to reduce thickness |

| Temperature | Usually hot or warm, depending on material | High temperature, above recrystallization point |

| Product Shape | Complex cross-sections, tubes, rods, profiles | Sheets, plates, strips with uniform thickness |

| Mechanical Properties | Improved strength and directional grain structure | Enhanced ductility and toughness |

| Surface Finish | Smoother surface, less scale | Rougher surface with scale, may require finishing |

| Material Waste | Low material waste due to precise shaping | Higher waste from trimming and scaling |

| Typical Materials | Aluminum, copper, plastics, steels | Steel, aluminum, copper alloys |

| Applications | Architectural profiles, automotive parts, tubing | Structural components, sheets for fabrication |

| Production Speed | Moderate to high, depending on complexity | High speed, suitable for mass production |

Introduction to Metal Forming Processes

Extrusion and hot rolling are critical metal forming processes used to shape metals by plastic deformation under high temperatures, enhancing material properties and structural integrity. Extrusion forces metal through a die to create complex cross-sectional profiles, while hot rolling compresses metal slabs between rolls to produce sheets or plates with improved grain structure. Understanding these processes is fundamental for manufacturing components with specific mechanical characteristics and dimensional accuracy in industries such as automotive, aerospace, and construction.

What is Extrusion?

Extrusion is a metal forming process where a billet is forced through a die under high pressure to create objects with a fixed cross-sectional profile, commonly used for aluminum and copper. This method enables the production of complex shapes with excellent surface finish and dimensional accuracy, often utilized in manufacturing pipes, rods, and custom profiles. Unlike hot rolling, extrusion allows greater design flexibility and is suitable for both hot and cold working conditions.

What is Hot Rolling?

Hot rolling is a metalworking process where metal is heated above its recrystallization temperature and then passed through rollers to achieve desired thickness and shape. This method improves material ductility, refines grain structure, and enhances mechanical properties such as strength and toughness. Compared to extrusion, hot rolling is more suitable for producing large, flat products like sheets and plates with consistent surface finish and dimensional accuracy.

Key Differences Between Extrusion and Hot Rolling

Extrusion involves forcing heated metal through a die to create long objects with a fixed cross-sectional profile, while hot rolling compresses heated metal between rollers to reduce thickness and improve mechanical properties. Extrusion offers precise cross-sectional control and allows for complex shapes, whereas hot rolling is optimized for large-scale production of flat sheets or plates. Temperature control, surface finish, and deformation rates differ significantly, with extrusion enabling higher dimensional accuracy and hot rolling providing better grain structure refinement.

Process Mechanics: Extrusion vs Hot Rolling

Extrusion forces a material through a shaped die, creating complex cross-sections with uniform mechanical properties and minimal waste, driven by compressive stress and high temperature to enhance ductility. Hot rolling involves passing heated metal between rollers to reduce thickness and refine grain structure, relying on compressive forces applied over large surface areas, leading to improved strength and surface finish. Both processes utilize high temperatures to increase material plasticity, but extrusion offers greater geometric complexity, while hot rolling excels in producing flat products with enhanced mechanical uniformity.

Materials Suitable for Each Process

Extrusion is highly suitable for materials with good plasticity, such as aluminum, copper, magnesium, and various plastics, due to their ability to flow under pressure without cracking. Hot rolling is optimal for metals like steel, stainless steel, and titanium alloys that require deformation at elevated temperatures to enhance ductility and refine grain structure. Materials with high melting points and strong crystalline structures are typically processed via hot rolling to achieve desired mechanical properties and surface finishes.

Advantages of Extrusion

Extrusion offers precise control over cross-sectional shapes, enabling the production of complex profiles with tight tolerances unlike hot rolling. Enhanced material uniformity and minimal waste result from the continuous nature of the extrusion process, improving cost efficiency. Extrusion also provides superior surface finish and mechanical properties due to controlled deformation and cooling rates.

Advantages of Hot Rolling

Hot rolling offers significant advantages including improved material ductility and reduced structural defects due to the high-temperature deformation process. This method enables mass production of large, uniform metal sheets and structural components with consistent mechanical properties. Enhanced surface finish and lower production costs make hot rolling a preferred choice for industries requiring high-strength steel products.

Common Applications of Extrusion and Hot Rolling

Extrusion is widely used in manufacturing complex aluminum profiles for automotive parts, window frames, and heat sinks due to its ability to create intricate cross-sections with excellent surface finish. Hot rolling is commonly applied in producing structural steel beams, railroad tracks, and large metal sheets for construction and heavy machinery, benefiting from improved mechanical properties and uniform grain structure. Both processes serve distinct industrial needs, with extrusion excelling in precision shapes and hot rolling ideal for bulk metal forming.

Selecting the Right Method for Your Project

Extrusion offers precise control over complex cross-sectional shapes and is ideal for producing long, uniform profiles with tight tolerances. Hot rolling, on the other hand, is suited for large-scale production of sheets, plates, and structural components with improved mechanical properties through controlled heating and deformation. Selecting the right method depends on project requirements such as material type, dimensional accuracy, production volume, and cost efficiency.

Extrusion Infographic

libterm.com

libterm.com