Time governs every aspect of our daily lives, influencing productivity, decision-making, and overall well-being. Mastering time management techniques can significantly enhance your efficiency and reduce stress. Explore the rest of this article to discover practical strategies for optimizing your time and achieving your goals.

Table of Comparison

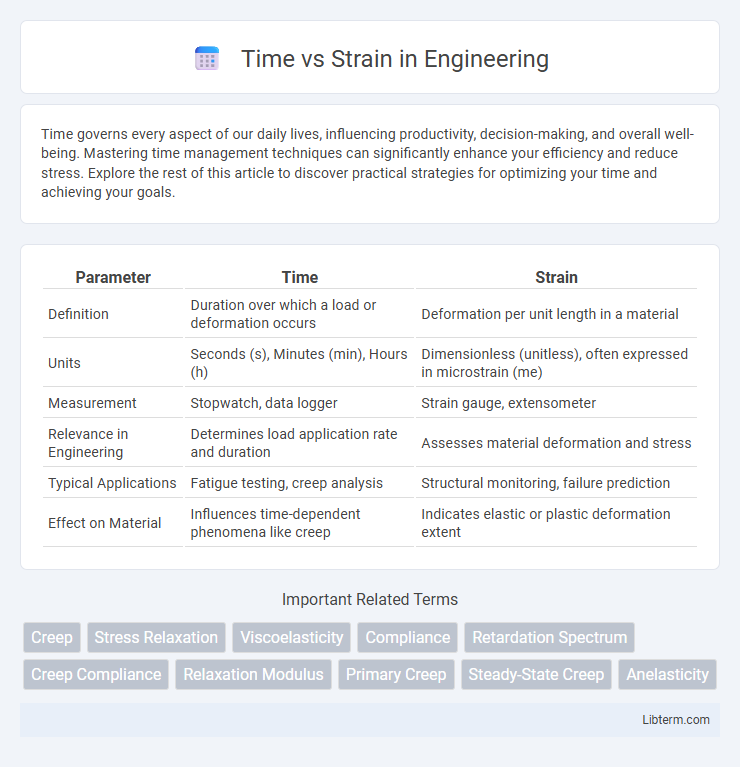

| Parameter | Time | Strain |

|---|---|---|

| Definition | Duration over which a load or deformation occurs | Deformation per unit length in a material |

| Units | Seconds (s), Minutes (min), Hours (h) | Dimensionless (unitless), often expressed in microstrain (me) |

| Measurement | Stopwatch, data logger | Strain gauge, extensometer |

| Relevance in Engineering | Determines load application rate and duration | Assesses material deformation and stress |

| Typical Applications | Fatigue testing, creep analysis | Structural monitoring, failure prediction |

| Effect on Material | Influences time-dependent phenomena like creep | Indicates elastic or plastic deformation extent |

Understanding the Concepts: Time and Strain

Time measures the continuous progression of events and is quantified in consistent units such as seconds, minutes, or hours. Strain represents the deformation or displacement material undergoes when subjected to stress, often expressed as a dimensionless ratio or percentage change in length. Understanding the relationship between time and strain is crucial in fields like materials science and engineering for predicting material behavior under prolonged stress.

The Science Behind Time-Dependent Strain

Time-dependent strain, also known as viscoelastic deformation, occurs when materials exhibit both viscous and elastic characteristics under prolonged stress. This behavior is governed by the material's internal molecular structure, which allows gradual rearrangement and slipping of polymer chains or crystalline defects over time. Understanding the science behind time-dependent strain is crucial for predicting long-term material performance in applications such as polymers, metals, and biological tissues.

Time vs Strain in Material Deformation

Time versus strain in material deformation critically influences viscoelastic behavior, where strain depends not only on applied stress but also on the duration of load application. Creep occurs when materials exhibit increasing strain over time under constant stress, while stress relaxation involves decreasing stress under constant strain as time progresses. Understanding these time-dependent deformation characteristics is essential for predicting long-term material performance and durability in engineering applications.

Types of Strain Influenced by Time

Time significantly impacts various types of strain, including elastic, plastic, and creep strain. Elastic strain occurs instantaneously and is recoverable upon load removal, while plastic strain accumulates irreversibly over time under sustained stress. Creep strain gradually develops during prolonged exposure to constant stress and elevated temperatures, causing material deformation that intensifies as time progresses.

Experimental Methods for Measuring Strain Over Time

Experimental methods for measuring strain over time primarily involve strain gauges, extensometers, and digital image correlation (DIC). Strain gauges bonded to a material's surface provide real-time electrical resistance changes corresponding to strain, enabling precise temporal strain measurement. Extensometers offer direct mechanical displacement tracking, while DIC employs optical techniques and high-resolution cameras to capture surface deformation, allowing for non-contact, full-field strain analysis during time-dependent testing.

Stress Relaxation and Creep: Key Time-Dependent Behaviors

Stress relaxation describes the gradual reduction in stress under a constant strain over time, revealing how materials redistribute internal forces to minimize deformation risks. Creep is characterized by a progressive increase in strain when a material is subjected to a constant stress, highlighting time-dependent deformation that can lead to eventual failure. Understanding these behaviors under varying temperatures and loading conditions is critical for predicting long-term material performance in structural applications.

Factors Affecting Strain with Time

Strain over time is influenced by material properties such as elasticity, creep resistance, and temperature sensitivity; materials with higher creep resistance exhibit less deformation under prolonged stress. Environmental factors like humidity and temperature accelerate strain, particularly in polymers and metals subjected to cyclic loading or high thermal exposure. Loading conditions, including magnitude, duration, and rate of applied stress, significantly affect time-dependent strain behavior, with sustained or fluctuating stresses causing greater cumulative deformation.

Real-World Applications: Engineering and Time-Dependent Strain

Time-dependent strain, also known as creep, plays a critical role in engineering applications such as turbine blades, bridges, and pipelines where materials are exposed to prolonged stress at high temperatures. Engineers must account for the gradual deformation over time in metals like nickel-based superalloys and polymers to ensure structural integrity and safety. Modeling creep behavior with time-strain curves enables accurate prediction of service life and maintenance schedules in real-world engineering systems.

Comparative Analysis: Instantaneous vs Delayed Strain

Instantaneous strain measures the immediate deformation response of a material under applied stress, capturing elastic behavior within milliseconds, while delayed strain reflects time-dependent viscous or viscoelastic effects resulting in gradual deformation over seconds to hours. Comparative analysis reveals that instantaneous strain dominates in brittle materials with minimal molecular mobility, whereas polymers and biological tissues exhibit significant delayed strain due to molecular relaxation and creep phenomena. Quantifying both strain types is crucial for predicting material performance under dynamic loading and long-term service conditions.

Future Perspectives in Time-Dependent Strain Research

Future perspectives in time-dependent strain research emphasize advancements in real-time monitoring technologies and predictive modeling to enhance material durability and performance under varying stress conditions. Integration of machine learning algorithms and high-resolution sensors enables precise characterization of strain evolution, facilitating the development of smart materials with adaptive properties. Ongoing studies focus on multiscale simulations and experimental validation to predict long-term behavior and failure mechanisms in engineering components subjected to complex loading histories.

Time Infographic

libterm.com

libterm.com