Bourdon tubes are precision instruments used to measure pressure by converting fluid pressure into mechanical displacement. Their curved, hollow design allows them to straighten or flex with changes in pressure, making them reliable for applications in industries such as HVAC, automotive, and manufacturing. Discover how a Bourdon tube can improve the accuracy and reliability of your pressure measurement in the rest of the article.

Table of Comparison

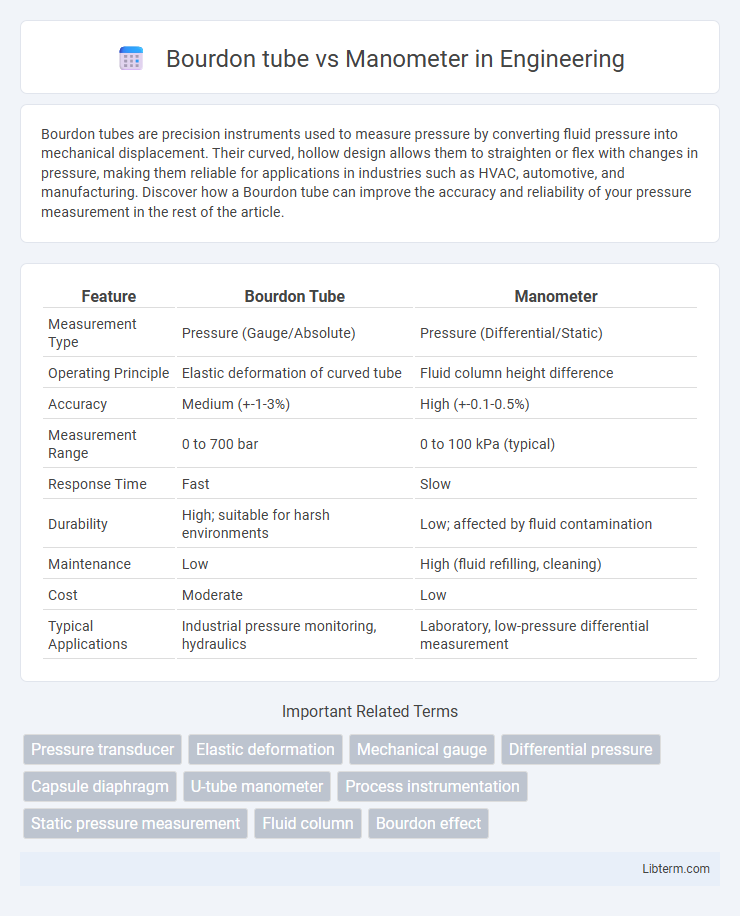

| Feature | Bourdon Tube | Manometer |

|---|---|---|

| Measurement Type | Pressure (Gauge/Absolute) | Pressure (Differential/Static) |

| Operating Principle | Elastic deformation of curved tube | Fluid column height difference |

| Accuracy | Medium (+-1-3%) | High (+-0.1-0.5%) |

| Measurement Range | 0 to 700 bar | 0 to 100 kPa (typical) |

| Response Time | Fast | Slow |

| Durability | High; suitable for harsh environments | Low; affected by fluid contamination |

| Maintenance | Low | High (fluid refilling, cleaning) |

| Cost | Moderate | Low |

| Typical Applications | Industrial pressure monitoring, hydraulics | Laboratory, low-pressure differential measurement |

Introduction to Pressure Measurement Devices

Bourdon tubes and manometers are fundamental pressure measurement devices widely used in industrial applications. Bourdon tubes convert pressure into mechanical displacement through a curved, flexible tube that straightens under pressure, providing precise readings suitable for high-pressure systems. Manometers measure pressure based on the height difference of a liquid column, offering simple and accurate measurements primarily for low-pressure or differential pressure scenarios.

Overview of Bourdon Tube Mechanism

The Bourdon tube mechanism operates through a curved, hollow tube that straightens when subjected to internal pressure, causing a connected pointer to move on a calibrated dial, thus indicating pressure levels. Unlike manometers, which rely on fluid column displacement to measure pressure, Bourdon tubes provide direct mechanical movement suitable for a wide range of pressures and environments. This type of pressure sensor is widely used in industrial applications due to its durability, accuracy, and ability to measure both gauge and absolute pressures.

Manometer: Principle and Types

Manometers operate on the principle of balancing the pressure of a fluid column against the pressure to be measured, using a liquid such as mercury or water to indicate pressure differences. Common types include the U-tube manometer, which measures pressure relative to atmospheric pressure; the differential manometer, designed to measure the difference between two pressure points; and the inclined manometer, which offers higher sensitivity for low-pressure measurements. These devices provide precise and reliable pressure readings, often preferred in laboratory and industrial applications for their simplicity and accuracy.

Key Differences Between Bourdon Tube and Manometer

Bourdon tubes measure pressure through the deformation of a curved tube that straightens as pressure increases, providing a mechanical indication of pressure, while manometers measure pressure by balancing fluid columns, relying on liquid displacement. Bourdon tubes are preferred for high-pressure applications due to their durability and suitability for portable or rugged environments, whereas manometers are more accurate for low-pressure measurements and laboratory settings. The Bourdon tube's calibration depends on tube material and shape, whereas manometers require a known fluid density and gravitational constant for pressure calculation.

Accuracy and Sensitivity Comparison

Bourdon tubes offer high accuracy for measuring medium to high pressure ranges, typically from 0 to 600 psi, with sensitivity influenced by tube material and geometry. Manometers provide superior sensitivity for low pressure and differential measurements, achieving accuracy within +-0.1% of the full scale through precise liquid column displacement. The choice between Bourdon tubes and manometers depends on the pressure range and sensitivity requirements, with manometers excelling in low-pressure applications while Bourdon tubes are preferred for robust, high-pressure environments.

Applications in Industry

Bourdon tubes are widely used in industrial applications requiring durability and accuracy for measuring high-pressure gases and liquids in sectors such as oil and gas, chemical plants, and manufacturing. Manometers, often employed in HVAC, laboratory settings, and low-pressure fluid systems, excel in monitoring pressure differentials and calibrating equipment due to their simplicity and precision at low pressures. The choice between Bourdon tube and manometer depends on pressure range, environment, and application-specific requirements in industries needing reliable pressure measurement solutions.

Advantages of Bourdon Tube

Bourdon tube gauges offer higher durability and resistance to mechanical shock compared to manometers, making them ideal for industrial applications. They provide quick, accurate pressure readings without the need for liquid calibration, eliminating risks of spills or freezing. Their compact design allows for easy installation in confined spaces where manometers may be impractical.

Advantages of Manometer

Manometers offer superior accuracy and sensitivity in pressure measurement, especially for low-pressure applications, compared to Bourdon tubes. Their simple design and lack of moving mechanical parts reduce maintenance needs and improve durability in harsh environments. Manometers also provide direct visual readings, enabling quick and precise monitoring without complex calibration.

Limitations and Drawbacks

Bourdon tubes have limited accuracy due to mechanical fatigue and sensitivity to temperature fluctuations, making them less reliable for precise pressure measurements over time. Manometers, while highly accurate, are constrained by their vulnerability to fluid contamination and difficulty in measuring high pressures or dynamic changes quickly. Both instruments face challenges with installation and maintenance in industrial environments, impacting long-term usability.

Choosing the Right Device for Your Application

Selecting between a Bourdon tube and a manometer depends on the pressure range, accuracy requirements, and environmental conditions of your application. Bourdon tubes excel in measuring high pressures up to several thousand psi with mechanical durability, making them suitable for industrial processes, while manometers offer high accuracy for low-pressure and differential pressure measurements in laboratory or HVAC settings. Consider factors such as response time, installation space, and maintenance needs to ensure optimal device performance and reliability.

Bourdon tube Infographic

libterm.com

libterm.com