Programmable Logic Controllers (PLCs) are essential industrial automation devices designed to control machinery and processes with high reliability and flexibility. These digital computers are programmed to monitor inputs and outputs, enabling precise control in manufacturing environments. Discover how PLCs can optimize your operations by exploring the detailed insights in this article.

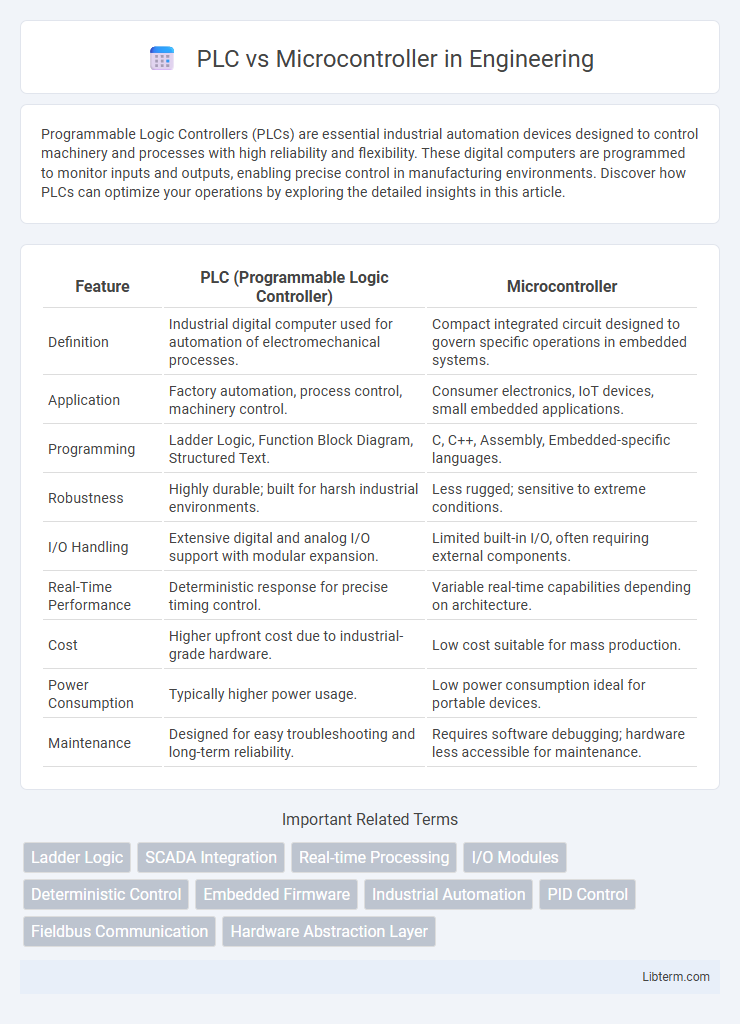

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | Microcontroller |

|---|---|---|

| Definition | Industrial digital computer used for automation of electromechanical processes. | Compact integrated circuit designed to govern specific operations in embedded systems. |

| Application | Factory automation, process control, machinery control. | Consumer electronics, IoT devices, small embedded applications. |

| Programming | Ladder Logic, Function Block Diagram, Structured Text. | C, C++, Assembly, Embedded-specific languages. |

| Robustness | Highly durable; built for harsh industrial environments. | Less rugged; sensitive to extreme conditions. |

| I/O Handling | Extensive digital and analog I/O support with modular expansion. | Limited built-in I/O, often requiring external components. |

| Real-Time Performance | Deterministic response for precise timing control. | Variable real-time capabilities depending on architecture. |

| Cost | Higher upfront cost due to industrial-grade hardware. | Low cost suitable for mass production. |

| Power Consumption | Typically higher power usage. | Low power consumption ideal for portable devices. |

| Maintenance | Designed for easy troubleshooting and long-term reliability. | Requires software debugging; hardware less accessible for maintenance. |

Introduction to PLCs and Microcontrollers

Programmable Logic Controllers (PLCs) are industrial digital computers designed to automate manufacturing processes with real-time control and robust operation in harsh environments. Microcontrollers are compact integrated circuits containing a processor, memory, and input/output peripherals, widely used for embedded system applications requiring precise, low-power control. Both technologies serve automation purposes but differ primarily in complexity, application scope, and environmental resilience.

Key Differences Between PLCs and Microcontrollers

PLCs (Programmable Logic Controllers) are industrial-grade devices designed for reliable automation and control in harsh environments, featuring built-in input/output modules and real-time processing capabilities. Microcontrollers are compact integrated circuits used in embedded systems, offering flexible, programmable control for specific tasks with limited I/O and processing power. Key differences include robustness, scalability, ease of programming, and suitability for complex industrial automation versus cost-effective, task-specific applications.

Architecture Comparison: PLC vs Microcontroller

Programmable Logic Controllers (PLCs) feature a rugged, modular architecture designed for industrial automation with dedicated input/output modules, a built-in power supply, and a processor optimized for real-time control tasks. Microcontrollers have a compact, integrated architecture combining a CPU, memory (RAM, ROM, EEPROM), and peripherals on a single chip, suited for embedded systems with flexible programming capability. PLCs emphasize standardized communication protocols and robustness for harsh environments, whereas microcontrollers prioritize low power consumption and versatility across diverse electronic applications.

Application Areas for PLCs and Microcontrollers

PLCs dominate industrial automation, controlling machinery, assembly lines, and process management in manufacturing due to their robustness and real-time reliability. Microcontrollers excel in embedded systems for consumer electronics, automotive controls, home appliances, and IoT devices, offering compact, cost-effective solutions with versatile programming. Both technologies serve distinct application areas where PLCs handle complex industrial environments while microcontrollers manage precise, low-power tasks in everyday products.

Programming Languages and Development Environments

PLC programming primarily utilizes ladder logic, structured text, and function block diagrams, all standardized under IEC 61131-3, ensuring compatibility across various industrial automation platforms. Microcontrollers support a broader range of programming languages including C, C++, Assembly, and Python, offering greater flexibility in embedded systems development. Development environments for PLCs are often vendor-specific and tailored for automation, while microcontroller IDEs like Arduino IDE, MPLAB, and Keil provide versatile debugging and simulation tools suited for diverse applications.

Performance and Processing Capabilities

PLCs offer robust performance for industrial automation with real-time processing, high reliability, and built-in input/output handling tailored for repetitive control tasks. Microcontrollers provide versatile processing capabilities with faster clock speeds, greater computational power, and flexible programming suited for complex algorithms and embedded systems. While PLCs excel in deterministic control environments, microcontrollers deliver superior raw processing power and adaptability for diverse applications.

Reliability and Industrial Suitability

PLCs (Programmable Logic Controllers) are engineered for high reliability in harsh industrial environments, featuring robust hardware resistant to temperature extremes, electrical noise, and mechanical vibrations. Microcontrollers, while versatile and cost-effective for embedded control applications, generally lack the industrial-grade durability and real-time deterministic performance essential for critical process automation. PLCs also offer standardized communication protocols and safety certifications, making them more suitable for complex industrial automation tasks where system uptime and fault tolerance are paramount.

Cost Considerations and Budget Analysis

PLCs typically involve higher upfront costs due to specialized hardware, programming software, and industrial-grade durability requirements, making them suitable for large-scale automation projects with significant budgets. Microcontrollers offer a more cost-effective solution for small to medium-scale applications, with lower hardware expenses and flexible programming environments, ideal for budget-sensitive designs. Careful budget analysis should consider not only initial acquisition costs but also maintenance, scalability, and long-term operational expenses to determine the most economically viable option.

Scalability and Future Expansion

PLCs offer superior scalability for industrial automation, supporting extensive I/O modules and networked devices, making them ideal for complex, evolving systems. Microcontrollers provide limited scalability due to fixed hardware resources and are best suited for smaller, dedicated tasks without significant expansion needs. Future expansion with PLCs is more manageable through modular designs and compatibility with industrial communication protocols, whereas microcontrollers often require redesign or replacement for enhanced functionality.

Choosing the Right Solution for Your Project

Selecting between a PLC and a microcontroller depends on factors such as project complexity, environment, and scalability. PLCs excel in industrial automation with robust reliability and easy integration, while microcontrollers offer flexible programming and cost-effectiveness for custom or low-volume applications. Consider factors like real-time control requirements, input/output needs, and future expansion to ensure the optimal fit for your project's objectives.

PLC Infographic

libterm.com

libterm.com