Surface flatness is critical in manufacturing processes to ensure components fit together precisely and function correctly. Maintaining optimal flatness reduces wear, improves assembly accuracy, and enhances product longevity. Explore the rest of the article to understand the techniques and tools for measuring and achieving perfect surface flatness.

Table of Comparison

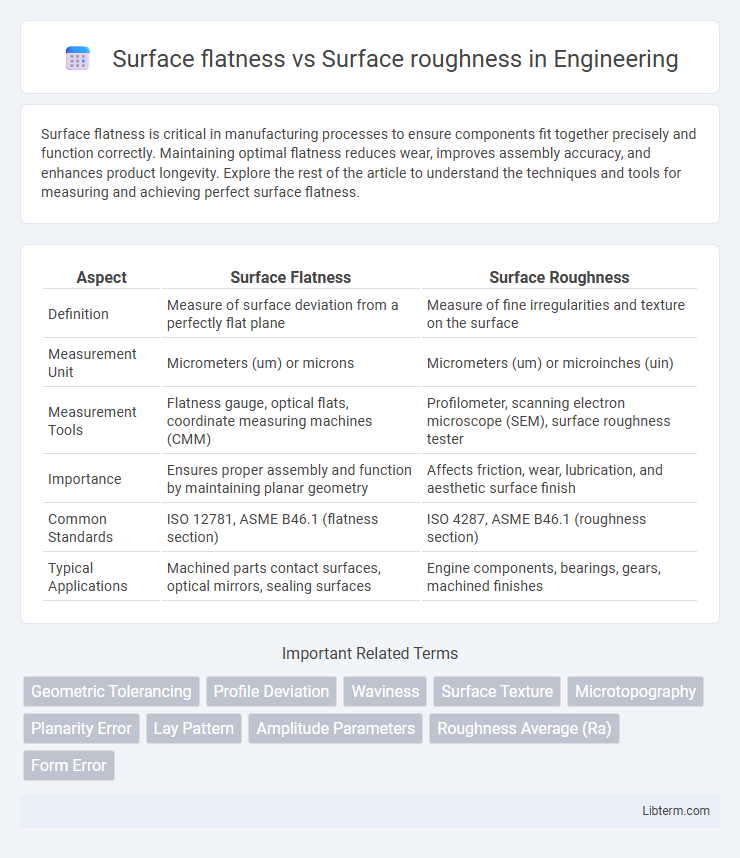

| Aspect | Surface Flatness | Surface Roughness |

|---|---|---|

| Definition | Measure of surface deviation from a perfectly flat plane | Measure of fine irregularities and texture on the surface |

| Measurement Unit | Micrometers (um) or microns | Micrometers (um) or microinches (uin) |

| Measurement Tools | Flatness gauge, optical flats, coordinate measuring machines (CMM) | Profilometer, scanning electron microscope (SEM), surface roughness tester |

| Importance | Ensures proper assembly and function by maintaining planar geometry | Affects friction, wear, lubrication, and aesthetic surface finish |

| Common Standards | ISO 12781, ASME B46.1 (flatness section) | ISO 4287, ASME B46.1 (roughness section) |

| Typical Applications | Machined parts contact surfaces, optical mirrors, sealing surfaces | Engine components, bearings, gears, machined finishes |

Introduction to Surface Flatness and Surface Roughness

Surface flatness refers to the degree to which a surface deviates from an ideal geometric plane, measured as the maximum distance between the highest and lowest points on the surface. Surface roughness describes the fine irregularities and texture of a surface, quantified by parameters like Ra (arithmetic average roughness) that capture small-scale variations. Both surface flatness and surface roughness are critical in manufacturing and engineering for ensuring proper fit, function, and performance of mechanical components.

Defining Surface Flatness

Surface flatness refers to the degree to which a surface deviates from an ideal plane, measuring the overall uniformity of the entire surface area. It is quantified by the maximum distance between the highest and lowest points on the surface, ensuring precise alignment and fit in mechanical assemblies. Unlike surface roughness, which describes fine texture irregularities at a micro scale, flatness addresses the macro-scale geometric form critical for functional performance.

Understanding Surface Roughness

Surface roughness quantifies the fine texture and irregularities on a material's surface at a microscopic scale, typically measured using parameters such as Ra (average roughness) and Rz (average peak-to-valley height). Unlike surface flatness, which assesses the overall deviation from a perfectly flat plane over a larger area, surface roughness focuses on small-scale surface deviations that affect friction, wear, and lubrication performance. Precise control and measurement of surface roughness are critical in manufacturing processes to ensure product functionality, improve lifespan, and optimize surface coatings or treatments.

Key Differences Between Surface Flatness and Surface Roughness

Surface flatness measures the overall deviation of a surface from an ideal plane, ensuring uniform height across the entire surface, while surface roughness quantifies the micro-scale texture variations and fine irregularities on the surface. Flatness is critical for applications requiring precise alignment and sealing between surfaces, whereas roughness affects friction, wear, and coating adhesion. Flatness is typically assessed using tools like laser interferometers or flatness gauges, whereas roughness is evaluated using profilometers that measure parameters such as Ra (average roughness) or Rz (mean peak-to-valley height).

Measurement Techniques for Surface Flatness

Surface flatness measurement techniques primarily include optical interferometry, coordinate measuring machines (CMM), and profilometry, each offering precise quantification of deviations from an ideal flat plane. Optical interferometry uses the interference of light waves to detect minute surface variations with nanometer accuracy, making it suitable for high-precision applications. Coordinate measuring machines provide three-dimensional spatial data by probing multiple points on a surface, enabling comprehensive flatness assessment across complex geometries.

Methods for Measuring Surface Roughness

Surface roughness is typically measured using contact profilometers that trace a stylus across the surface to capture micro-level texture variations, providing detailed roughness parameters such as Ra and Rz. Non-contact methods include optical techniques like laser scanning and white light interferometry that offer high-resolution surface profiles without physical contact, ideal for delicate or soft materials. These measurement methods differ significantly from surface flatness assessments, which focus on the macro-scale geometric deviation of a surface plane rather than micro-scale texture features.

Importance of Surface Flatness in Engineering Applications

Surface flatness is crucial in engineering applications because it directly affects the precision, functionality, and longevity of assembled components, ensuring proper alignment and load distribution. Unlike surface roughness, which measures microscopic texture, flatness determines the overall evenness of a surface, impacting sealing, wear resistance, and mechanical performance. Maintaining stringent flatness tolerances is essential in high-precision industries such as aerospace, automotive, and semiconductor manufacturing to achieve optimal operational efficiency and product reliability.

Significance of Surface Roughness in Functional Performance

Surface roughness directly impacts functional performance by influencing friction, wear resistance, and lubrication retention on mating surfaces. Precise control of surface roughness enhances sealing efficiency, reduces fatigue initiation sites, and improves overall component lifespan in mechanical assemblies. In contrast, surface flatness primarily ensures geometric conformity but does not address micro-level texture affecting operational behavior.

Interrelation Between Surface Flatness and Roughness

Surface flatness and surface roughness are critical parameters that define the quality of a machined surface, where flatness measures the overall geometric deviation from an ideal plane, and roughness quantifies the fine texture variations. These attributes are interrelated since improvements in surface flatness often reduce surface roughness, enhancing the contact performance and wear resistance of components such as precision machine parts and optical lenses. Controlling machining processes like grinding and polishing can optimize both flatness and roughness, thereby increasing functional reliability in critical applications.

Surface Flatness vs Surface Roughness: Choosing the Right Metric

Surface flatness measures the overall evenness of a surface relative to a reference plane, ensuring uniform geometric form without deviations beyond specified limits. Surface roughness quantifies the fine texture on a surface, characterized by microscopic peaks and valleys that affect friction, wear, and appearance. Selecting the right metric depends on application requirements: flatness is critical for assembly fit and sealing, while roughness impacts functionality and aesthetic quality.

Surface flatness Infographic

libterm.com

libterm.com