Stress intensity measures the concentration of stress around a flaw or crack tip in a material, crucial for predicting failure in engineering structures. Understanding this concept helps you evaluate the durability and safety of components under various loading conditions. Explore the full article to learn how stress intensity influences material performance and failure prevention.

Table of Comparison

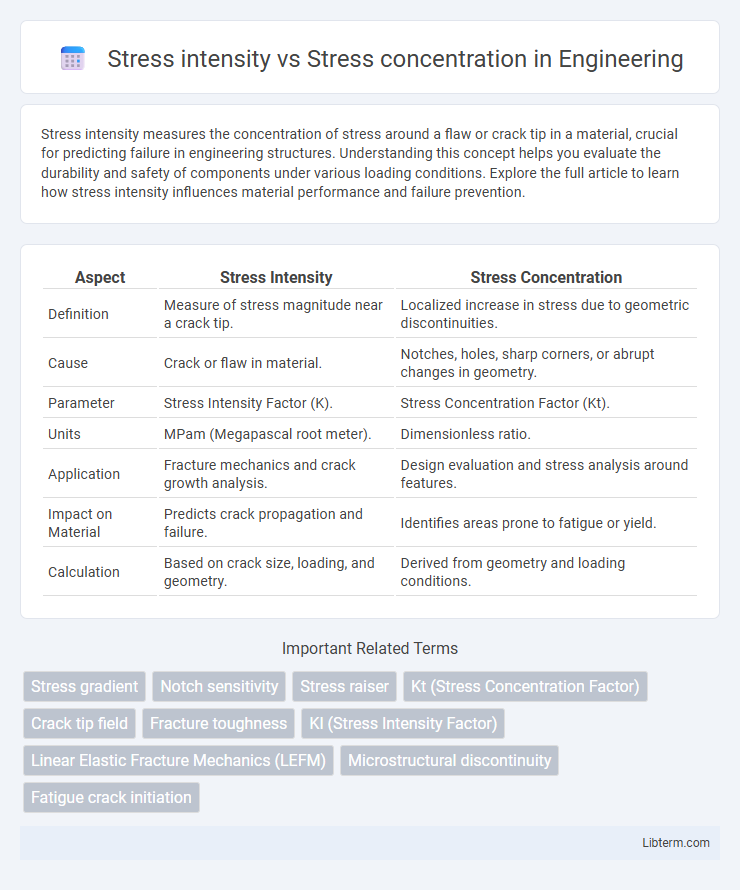

| Aspect | Stress Intensity | Stress Concentration |

|---|---|---|

| Definition | Measure of stress magnitude near a crack tip. | Localized increase in stress due to geometric discontinuities. |

| Cause | Crack or flaw in material. | Notches, holes, sharp corners, or abrupt changes in geometry. |

| Parameter | Stress Intensity Factor (K). | Stress Concentration Factor (Kt). |

| Units | MPam (Megapascal root meter). | Dimensionless ratio. |

| Application | Fracture mechanics and crack growth analysis. | Design evaluation and stress analysis around features. |

| Impact on Material | Predicts crack propagation and failure. | Identifies areas prone to fatigue or yield. |

| Calculation | Based on crack size, loading, and geometry. | Derived from geometry and loading conditions. |

Understanding Stress Intensity and Stress Concentration

Stress intensity refers to the magnitude of stress at a specific point, especially near the tip of a crack, where it governs crack propagation in fracture mechanics. Stress concentration describes localized increases in stress around geometric discontinuities such as holes, notches, or sharp corners, which can lead to material failure if not properly managed. Understanding the difference between stress intensity and stress concentration is crucial for predicting structural behavior and designing components to resist fracture and fatigue.

Key Differences Between Stress Intensity and Stress Concentration

Stress intensity refers to the magnitude of stress at a specific point near the tip of a crack in a material, quantified by the Stress Intensity Factor (K), which predicts crack propagation under various loading conditions. Stress concentration involves localized increases in stress caused by geometric discontinuities such as holes, notches, or sudden changes in cross-section, characterized by the Stress Concentration Factor (Kt). The key difference lies in stress intensity being associated with crack tip behavior and fracture mechanics, while stress concentration relates to areas of geometric irregularities causing stress amplification without necessarily involving crack initiation.

Origins and Causes of Stress Concentration

Stress concentration originates from abrupt changes in material geometry, such as notches, holes, or sharp corners, causing localized increases in stress beyond the average stress in the component. These geometrical discontinuities disrupt the uniform distribution of stress, leading to amplification factors that can significantly exceed nominal stress values and initiate cracks or failure. Unlike stress intensity, which quantifies stress near crack tips, stress concentration specifically refers to the amplification of stress caused by structural irregularities or defects inherent in design or manufacturing processes.

Factors Influencing Stress Intensity

Stress intensity in materials depends on factors such as the magnitude of the applied load, the crack length, and the crack geometry, which together determine the stress intensity factor (K). Material properties like fracture toughness and environmental conditions also influence how stress concentrates near crack tips. Precise control over these variables is essential to predict fracture behavior and prevent material failure.

Mathematical Representation of Stress Intensity

Stress intensity is mathematically represented by the Stress Intensity Factor (K), which quantifies the stress state near the tip of a crack and is essential in fracture mechanics for predicting crack propagation. Unlike stress concentration, which refers to localized stress amplification due to geometric discontinuities and is often described by a dimensionless stress concentration factor (Kt), stress intensity uses the equation \( K = \sigma \sqrt{\pi a} \) for mode I loading, where \( \sigma \) is the applied stress and \( a \) is the crack length. The stress intensity factor directly relates to the energy release rate and critical fracture toughness, providing a critical metric for structural integrity assessments under varying stress fields.

Stress Concentration Factors (SCF): Definition and Importance

Stress Concentration Factors (SCF) quantify the increase in localized stress around geometric discontinuities such as holes, notches, or grooves, compared to the nominal stress in a material. SCF is critical in structural analysis and design because it helps predict potential failure points by identifying areas where stress significantly exceeds average levels, leading to crack initiation and propagation. Understanding and accurately calculating SCF enables engineers to optimize component geometry, improve durability, and ensure safety under applied loads.

Effects of Geometry and Material Defects on Stress Concentration

Stress intensity measures the magnitude of stress near the tip of a crack, crucial for predicting fracture behavior, while stress concentration refers to localized stress amplification caused by abrupt changes in geometry or material defects. Sharp corners, notches, holes, and surface cracks significantly elevate stress concentration factors, leading to potential initiation sites for cracks and fatigue failure. Material defects such as inclusions, voids, and microcracks exacerbate stress concentration by disrupting uniform stress distribution, thereby increasing susceptibility to crack propagation and structural failure.

Real-World Examples: Stress Intensity vs Stress Concentration

Stress intensity quantifies the magnitude of stress near the tip of a crack, critical for predicting crack growth in materials like aircraft fuselages under cyclic loading. Stress concentration refers to localized stress amplifications caused by geometric discontinuities such as holes, notches, or sharp corners, exemplified by stress buildup around bolt holes in bridge structures. Real-world engineering assessments use stress intensity factors for fracture analysis, while stress concentration factors guide design modifications to minimize failure risks in mechanical components.

Methods for Reducing Stress Concentration

Stress concentration occurs at geometric discontinuities causing localized increases in stress, whereas stress intensity relates to the magnitude of stress near a crack tip in fracture mechanics. Methods for reducing stress concentration include introducing fillets or smooth transitions at sharp corners, using uniform cross-sections, and applying surface treatments such as shot peening to enhance material strength. Optimizing design geometry and selecting materials with high fracture toughness further mitigate stress concentration effects, improving structural durability.

Practical Applications in Engineering Design

Stress intensity describes the magnitude of stress at the tip of a crack, critical for fracture mechanics and predicting crack propagation in materials under load. Stress concentration refers to localized increases in stress around geometric discontinuities such as holes, notches, or sharp corners, influencing failure points in structural components. Engineering design uses stress intensity to assess crack growth and fatigue life while applying stress concentration factors to optimize shapes, reduce stress risers, and enhance durability in mechanical parts.

Stress intensity Infographic

libterm.com

libterm.com