An edge joint is a woodworking technique where two pieces of wood are joined along their edges to create a wider panel or surface. This method ensures a strong, seamless bond that enhances the structural integrity and aesthetic appeal of your project. Discover the key steps and tips to master edge jointing in the rest of this article.

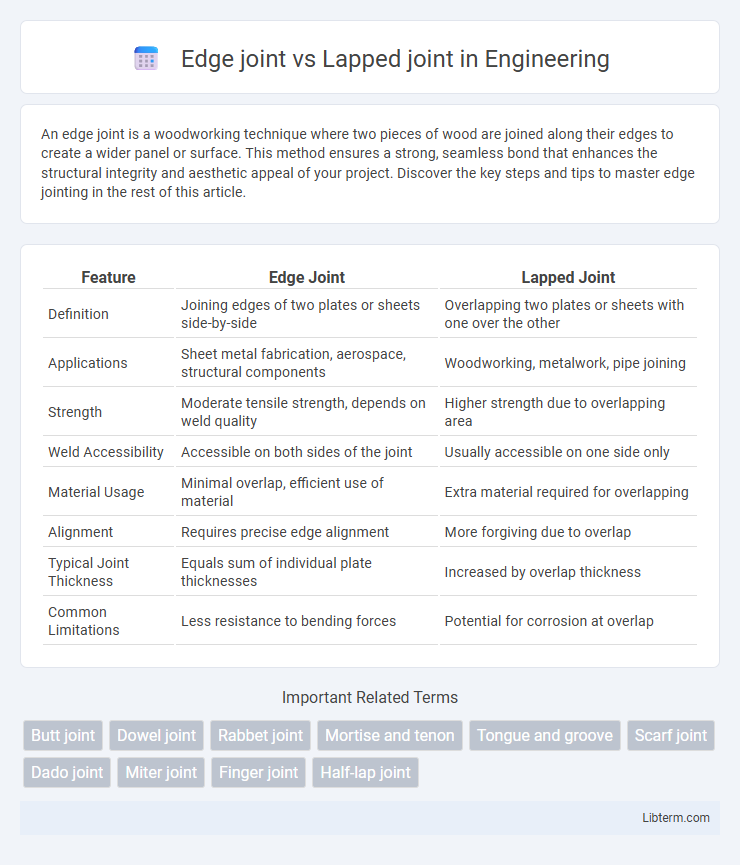

Table of Comparison

| Feature | Edge Joint | Lapped Joint |

|---|---|---|

| Definition | Joining edges of two plates or sheets side-by-side | Overlapping two plates or sheets with one over the other |

| Applications | Sheet metal fabrication, aerospace, structural components | Woodworking, metalwork, pipe joining |

| Strength | Moderate tensile strength, depends on weld quality | Higher strength due to overlapping area |

| Weld Accessibility | Accessible on both sides of the joint | Usually accessible on one side only |

| Material Usage | Minimal overlap, efficient use of material | Extra material required for overlapping |

| Alignment | Requires precise edge alignment | More forgiving due to overlap |

| Typical Joint Thickness | Equals sum of individual plate thicknesses | Increased by overlap thickness |

| Common Limitations | Less resistance to bending forces | Potential for corrosion at overlap |

Introduction to Edge Joints and Lapped Joints

Edge joints connect the edges of two boards to create a wider surface, commonly used in panel construction and woodworking projects requiring seamless joins. Lapped joints overlap the material surfaces, increasing the glue area and enhancing joint strength, often employed in framing and furniture making. Both joint types offer distinct structural benefits, with edge joints prioritizing flat surface continuity and lapped joints providing reinforcement through overlapping material.

Definition of Edge Joint

An edge joint is a woodworking technique where two pieces of wood are joined along their edges to create a wider board, commonly used for tabletops and panels. This joint provides a smooth, continuous surface by aligning grain patterns and ensuring even thickness. In contrast, a lapped joint overlaps two pieces by cutting one or both at the joint to increase surface area and strength.

Definition of Lapped Joint

A lapped joint is a type of connection where two overlapping surfaces are fastened together to provide increased strength and surface area for bonding or welding. In comparison, edge joints connect two pieces along their edges without overlapping, primarily used for joining sheet metals or plates. Lapped joints are commonly employed in woodworking, metalworking, and construction for creating durable and stable assemblies.

Key Differences Between Edge and Lapped Joints

Edge joints connect two boards along their edges to create a wider surface, primarily used for panel glue-ups, while lapped joints involve overlapping two pieces to increase surface area and strength. Edge joints provide a flush surface ideal for tabletops and countertops, whereas lapped joints offer greater mechanical strength, commonly used in framing and box construction. The key difference lies in the joint's geometry and application: edge joints align boards edge-to-edge, lapped joints partially overlap, enhancing joint stability and load resistance.

Strength Comparison: Edge Joint vs Lapped Joint

Edge joints provide moderate strength by aligning boards side-by-side, making them suitable for lightweight applications where stability is needed but heavy loads are absent. Lapped joints offer superior strength due to the increased overlapping surface area, which enhances load distribution and resistance to shear forces, making them ideal for structural and heavy-duty uses. When comparing the two, lapped joints outperform edge joints in terms of tensile and shear strength, ensuring a more durable and robust connection.

Applications of Edge Joints

Edge joints are commonly used in woodworking and metalworking to create wider surfaces by joining two narrow boards or metal pieces along their edges, making them ideal for tabletops, panels, and wide boards. They provide a seamless surface that maintains strength and durability in furniture manufacturing and cabinetry. Unlike lapped joints, edge joints offer a flush alignment, enhancing aesthetic appeal in decorative woodwork and precision assemblies.

Applications of Lapped Joints

Lapped joints are commonly used in woodworking, metalworking, and construction due to their strength and ease of assembly, making them ideal for frames, doors, and panels. Their overlapping design provides increased surface area for adhesive or fasteners, enhancing load distribution and joint durability in structures such as furniture, cabinetry, and roofing. They also accommodate slight misalignments, making lapped joints preferable in applications requiring precise alignment and structural integrity.

Advantages and Disadvantages of Edge Joints

Edge joints provide a smooth, continuous surface ideal for creating wider boards and panels, enhancing aesthetic appeal and structural uniformity. They offer strong resistance to bending forces but can be weaker against shear stress if not properly reinforced or glued. The main disadvantage includes potential misalignment during assembly, which can compromise joint strength and appearance if precise clamping and adhesive application are not maintained.

Advantages and Disadvantages of Lapped Joints

Lapped joints offer advantages such as improved strength and stability by overlapping two materials, which increases the surface area for bonding or fastening. They are relatively easy to make and provide better resistance to bending and tension compared to edge joints. However, lapped joints may cause misalignment or uneven surfaces, require more material overlap leading to increased weight, and can be prone to stress concentration at the overlap area, potentially reducing long-term durability.

Choosing the Right Joint for Your Project

Selecting between an edge joint and a lapped joint depends on the structural requirements and aesthetic goals of your project. Edge joints provide a smooth, continuous surface ideal for panels or tabletops where strength and seamless appearance are essential. Lapped joints offer increased mechanical strength and are better suited for frames or load-bearing connections where overlapping surfaces distribute stress more effectively.

Edge joint Infographic

libterm.com

libterm.com