A rocker arm plays a crucial role in an engine's valve train by transferring camshaft motion to open and close the valves, ensuring efficient fuel combustion and engine performance. Proper maintenance of rocker arms can prevent engine noise and wear, prolonging the life of your vehicle's engine components. Discover more about how rocker arms function and their importance in your engine by reading the rest of this article.

Table of Comparison

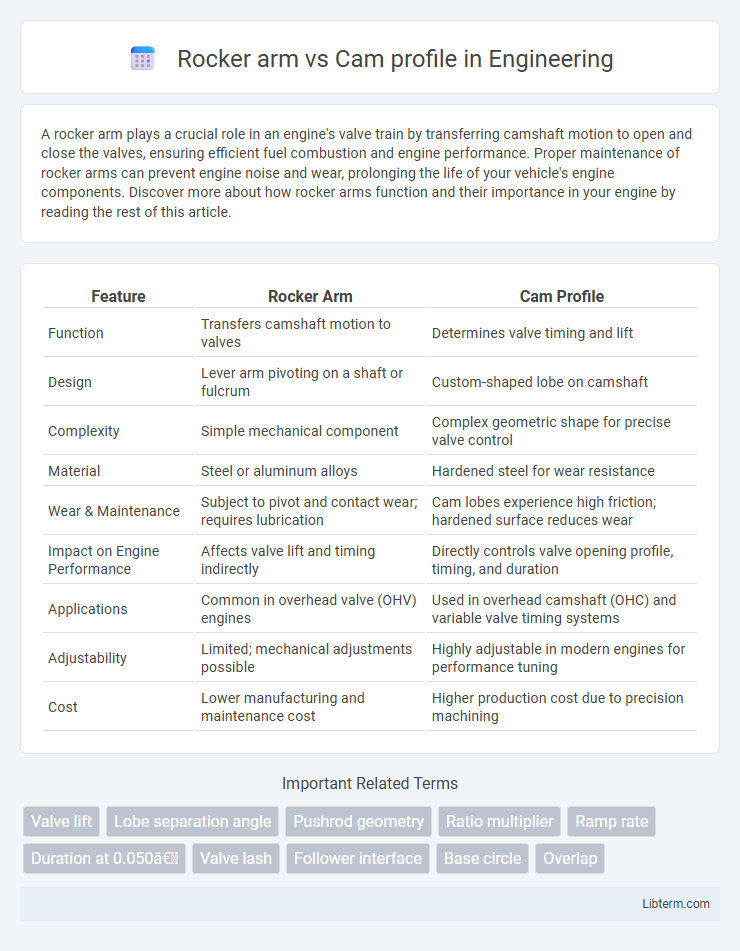

| Feature | Rocker Arm | Cam Profile |

|---|---|---|

| Function | Transfers camshaft motion to valves | Determines valve timing and lift |

| Design | Lever arm pivoting on a shaft or fulcrum | Custom-shaped lobe on camshaft |

| Complexity | Simple mechanical component | Complex geometric shape for precise valve control |

| Material | Steel or aluminum alloys | Hardened steel for wear resistance |

| Wear & Maintenance | Subject to pivot and contact wear; requires lubrication | Cam lobes experience high friction; hardened surface reduces wear |

| Impact on Engine Performance | Affects valve lift and timing indirectly | Directly controls valve opening profile, timing, and duration |

| Applications | Common in overhead valve (OHV) engines | Used in overhead camshaft (OHC) and variable valve timing systems |

| Adjustability | Limited; mechanical adjustments possible | Highly adjustable in modern engines for performance tuning |

| Cost | Lower manufacturing and maintenance cost | Higher production cost due to precision machining |

Introduction to Rocker Arm and Cam Profile

The rocker arm is a pivotal component in an internal combustion engine's valve train that transfers camshaft motion to open and close the engine valves. The cam profile refers to the specific shape of the camshaft lobes, determining the valve timing, duration, and lift, which directly impacts engine performance and efficiency. Understanding the relationship between the rocker arm and cam profile is essential for optimizing valve operation in various engine designs.

Understanding Rocker Arm Functions

Rocker arms play a crucial role in the valve train system by transferring the camshaft's rotational motion into linear movement to open and close valves efficiently. Unlike the cam profile, which directly shapes the timing and lift characteristics, the rocker arm acts as an intermediary lever that amplifies or modifies camshaft motion to optimize valve operation. Understanding the rocker arm's function helps improve engine performance, durability, and valve timing precision.

Exploring Cam Profile Design

Cam profile design directly influences valve timing, lift, and engine performance by controlling the motion transferred to the rocker arm. Optimizing cam profiles involves precise shaping to maximize valve opening efficiency, reduce wear, and improve fuel combustion. Advanced cam profiles tailored to specific rocker arm geometries can enhance engine responsiveness and torque output.

Key Differences: Rocker Arm vs Cam Profile

The key differences between a rocker arm and a cam profile lie in their roles and mechanical functions within an engine's valve train. The cam profile directly controls the valve timing and lift by transforming rotational motion into precise valve movement, while the rocker arm acts as a lever transmitting this motion from the camshaft to the valves, amplifying or changing the direction of force. Understanding the variations in design and operation of these components is crucial for optimizing engine performance, durability, and efficiency.

Impact on Valve Timing and Lift

Rocker arms directly influence valve timing and lift by translating camshaft motion into precise valve actuation; their geometry affects the valve's opening speed and duration. Cam profiles determine the shape and extent of valve movement, controlling the lift height and timing intervals critical for engine performance. Optimizing the interaction between rocker arm ratio and cam profile ensures accurate valve events, maximizing airflow and combustion efficiency.

Performance Implications for Engines

Rocker arms influence valve lift and timing by translating camshaft motion into precise valve actuation, directly affecting engine breathing and high-RPM performance. Cam profiles dictate valve opening duration and lift, shaping the engine's torque curve and power delivery characteristics. Optimizing the interplay between rocker arm geometry and cam profile improves airflow efficiency, combustion, and overall engine responsiveness.

Durability and Maintenance Considerations

Rocker arms typically exhibit higher durability due to their simpler mechanical design and robust construction, requiring less frequent maintenance compared to complex cam profiles that experience greater wear from direct valve contact. Cam profiles demand precise lubrication and periodic inspection to prevent accelerated wear and potential failure in high-performance engines. Regular maintenance of rocker arms often involves minimal adjustments, whereas cams necessitate careful monitoring of lobe wear and follower condition to ensure optimal valve timing and longevity.

Aftermarket Upgrades: Rocker Arms and Cam Profiles

Aftermarket upgrades for rocker arms and cam profiles significantly enhance engine performance by optimizing valve lift and timing. High-quality rocker arms reduce friction and increase stability, allowing for more aggressive cam profiles that boost power and torque. Custom cam profiles improve airflow dynamics, complementing upgraded rocker arms for maximum efficiency and durability in performance engines.

Choosing the Right Setup for Your Engine

Selecting the appropriate rocker arm and cam profile combination is essential for optimizing engine performance and efficiency. High-lift cam profiles paired with lightweight, roller rocker arms reduce friction and enable greater valve lift, improving horsepower and torque output. Consider factors such as engine RPM range, desired power characteristics, and compatibility with valve train components to achieve the best setup tailored to your engine's specific needs.

Conclusion: Optimizing Valve Train Performance

Rocker arms and cam profiles both play critical roles in optimizing valve train performance by controlling valve timing and lift with precision. Selecting a cam profile tailored to the engine's desired powerband maximizes airflow efficiency, while a well-designed rocker arm ensures smooth and accurate valve actuation under high RPM conditions. Combining an optimized cam profile with lightweight, durable rocker arms enhances overall engine responsiveness and durability.

Rocker arm Infographic

libterm.com

libterm.com