Hardness measures a material's resistance to deformation, scratching, or indentation, playing a critical role in determining its durability and wear resistance. Understanding hardness is essential for selecting appropriate materials in construction, manufacturing, and tool design. Explore the rest of this article to discover how hardness affects material performance and testing methods.

Table of Comparison

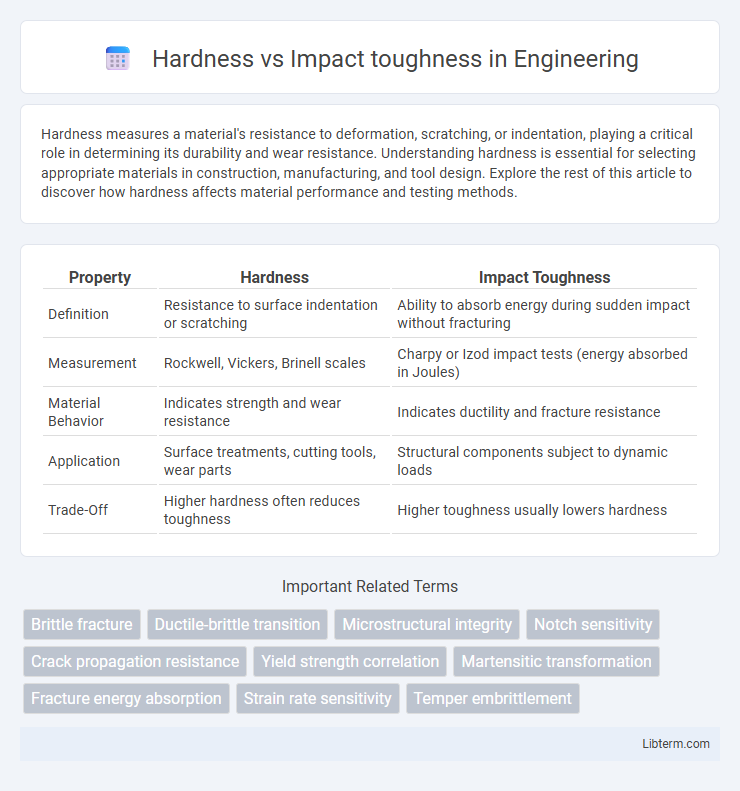

| Property | Hardness | Impact Toughness |

|---|---|---|

| Definition | Resistance to surface indentation or scratching | Ability to absorb energy during sudden impact without fracturing |

| Measurement | Rockwell, Vickers, Brinell scales | Charpy or Izod impact tests (energy absorbed in Joules) |

| Material Behavior | Indicates strength and wear resistance | Indicates ductility and fracture resistance |

| Application | Surface treatments, cutting tools, wear parts | Structural components subject to dynamic loads |

| Trade-Off | Higher hardness often reduces toughness | Higher toughness usually lowers hardness |

Introduction to Hardness and Impact Toughness

Hardness measures a material's resistance to deformation or indentation, reflecting its surface strength and wear resistance, while impact toughness indicates a material's ability to absorb energy during sudden force or shock without fracturing. Both properties are critical in material selection for engineering applications, with hardness often linked to wear resistance and impact toughness related to fracture resistance under dynamic loading. Understanding the balance between hardness and impact toughness is essential for optimizing materials in industries such as automotive, aerospace, and construction.

Defining Hardness: Key Concepts

Hardness measures a material's resistance to localized plastic deformation, such as indentation or scratching, influencing wear resistance and surface durability. It is typically assessed using tests like Rockwell, Vickers, or Brinell, which provide quantitative values reflecting a material's structural integrity under penetration. Understanding hardness is crucial for applications requiring resistance to abrasion, while impact toughness evaluates a material's ability to absorb energy during sudden force or impact, highlighting the practical differences between these mechanical properties.

Understanding Impact Toughness

Impact toughness measures a material's ability to absorb energy and resist fracture under sudden or dynamic loading, which is critical in applications involving shock or impact stresses. Unlike hardness, which indicates resistance to indentation or wear, impact toughness evaluates the material's capacity to withstand brittle failure by absorbing kinetic energy before cracking. Understanding impact toughness helps engineers select materials that maintain structural integrity under rapid stress changes, enhancing safety and durability in critical components.

Measuring Hardness: Common Methods

Measuring hardness involves several common methods, including the Brinell, Rockwell, and Vickers tests, each designed to evaluate a material's resistance to indentation under specific loads and indenter types. These methods provide essential data that correlates to wear resistance but do not directly measure impact toughness, which assesses a material's ability to absorb energy during sudden force. Understanding the distinction between hardness and impact toughness is crucial for selecting materials that balance surface durability with the capacity to withstand shock loading.

Testing Impact Toughness: Techniques and Standards

Impact toughness testing measures a material's ability to absorb energy and resist fracture under sudden loading, commonly executed using Charpy and Izod test methods. These standardized tests, defined by ASTM E23 and ISO 148, involve striking a notched specimen with a pendulum hammer to quantify energy absorbed during breakage. Understanding impact toughness provides critical insights into a material's fracture resistance in dynamic conditions, complementing hardness tests that assess resistance to permanent deformation.

Relationship Between Hardness and Impact Toughness

The relationship between hardness and impact toughness is typically inverse, as materials with higher hardness often exhibit lower impact toughness due to increased brittleness. Hardness measures resistance to deformation, while impact toughness quantifies a material's ability to absorb energy during rapid loading or impact. Optimizing material performance requires balancing hardness to provide wear resistance without compromising the ability to withstand sudden stress or fracture.

Factors Influencing Hardness and Toughness

Hardness depends on factors like material composition, heat treatment, and grain size, which influence resistance to deformation or scratching. Impact toughness is affected by microstructure, temperature, and strain rate, determining a material's ability to absorb energy during sudden impacts. Balancing these factors is crucial in selecting materials for applications requiring both durability and shock resistance.

Industrial Applications: Selecting for Hardness or Toughness

In industrial applications, selecting materials based on hardness or impact toughness depends on the specific operational demands; hardness offers wear resistance and durability in abrasive environments, while impact toughness ensures resistance to sudden shocks and fractures. Hardness is critical in cutting tools and wear-resistant surfaces where surface deformation must be minimized, whereas impact toughness is vital for structural components subjected to dynamic or impact loads, such as automotive chassis and heavy machinery parts. Balancing hardness and toughness requires understanding the trade-offs, as higher hardness often reduces toughness, influencing choices in heat treatment processes and alloy composition for optimal performance.

Material Examples: Case Studies and Comparisons

Tool steels such as A2 exhibit high hardness values around 60 HRC, offering excellent wear resistance but relatively low impact toughness, limiting their use in dynamic loading conditions. In contrast, alloyed steels like AISI 4340 provide a balanced combination of medium hardness (around 30-40 HRC) with high impact toughness, making them suitable for aerospace components subjected to variable stresses. Case studies on these materials reveal that optimizing the heat treatment process in 4340 steel significantly enhances impact toughness without severely compromising hardness, demonstrating a critical trade-off in material selection for structural applications.

Conclusion: Balancing Hardness and Impact Toughness

Balancing hardness and impact toughness requires optimizing material composition and heat treatment processes to achieve desired mechanical properties without compromising durability. High hardness improves wear resistance but often reduces impact toughness, increasing brittleness under sudden loads. Engineering applications demand a tailored compromise, ensuring sufficient hardness for strength while maintaining impact toughness for damage tolerance and reliable performance.

Hardness Infographic

libterm.com

libterm.com