Radial load refers to the force applied perpendicular to the axis of a rotating component, impacting bearings and shafts by pushing them inward or outward along a horizontal plane. Understanding how radial loads affect mechanical parts is crucial for optimizing machine performance and preventing premature wear. Discover how managing radial loads can enhance your equipment's reliability by reading the full article.

Table of Comparison

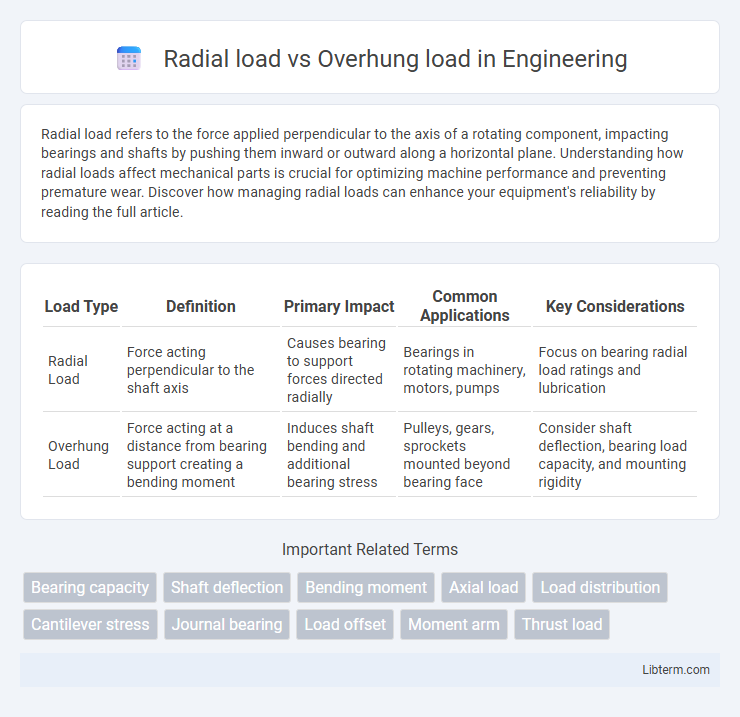

| Load Type | Definition | Primary Impact | Common Applications | Key Considerations |

|---|---|---|---|---|

| Radial Load | Force acting perpendicular to the shaft axis | Causes bearing to support forces directed radially | Bearings in rotating machinery, motors, pumps | Focus on bearing radial load ratings and lubrication |

| Overhung Load | Force acting at a distance from bearing support creating a bending moment | Induces shaft bending and additional bearing stress | Pulleys, gears, sprockets mounted beyond bearing face | Consider shaft deflection, bearing load capacity, and mounting rigidity |

Introduction to Radial Load and Overhung Load

Radial load refers to the force applied perpendicular to the shaft axis, causing stress mainly on the bearing's outer ring, while overhung load involves a load acting at a distance from the bearing's support, creating bending moments on the shaft. Understanding the distinction between these forces is crucial for selecting proper bearing types and ensuring mechanical system durability. Radial loads are common in rotating machinery, whereas overhung loads often occur in applications with extended shafts or mounted components.

Defining Radial Load in Mechanical Systems

Radial load in mechanical systems refers to force applied perpendicular to the shaft axis, impacting bearing performance by creating stress on bearing components. This load type primarily influences bearing life and shaft alignment, requiring accurate calculation for optimal equipment functionality. Understanding radial load is crucial for selecting appropriate bearings and ensuring mechanical system reliability under operational conditions.

Understanding Overhung Load: Concepts and Importance

Overhung load refers to the radial force exerted on a bearing when a load acts at a distance from the bearing's support point, creating a bending moment that can affect bearing performance and lifespan. Understanding overhung load is crucial for selecting appropriate bearings and designing shafts to withstand these moments without premature failure. Proper assessment ensures enhanced reliability and operational efficiency in rotating machinery where radial loads act with offset lever arms.

Fundamental Differences Between Radial and Overhung Loads

Radial loads act perpendicular to the shaft axis, primarily causing bending stress within the bearing, while overhung loads generate axial forces and moments that induce combined bending and axial stresses. Radial loads typically occur in applications like rotating shafts supported by bearings, whereas overhung loads are common in cantilevered setups where the load is offset from the bearing support. Understanding the direction and resultant stresses is crucial for selecting appropriate bearings and ensuring mechanical reliability.

Factors Influencing Radial Load Capacity

Radial load capacity primarily depends on bearing type, material strength, and internal design features like cage and lubrication quality. Shaft diameter, operating speed, and temperature also critically influence radial load limits by affecting deformation and wear resistance. Environmental factors such as contamination and moisture can further reduce a bearing's effective radial load capacity by accelerating surface damage.

Impact of Overhung Load on Equipment Performance

Overhung load significantly impacts equipment performance by increasing bending stress on shafts, which can lead to premature bearing failure and reduced lifespan of rotating machinery. Unlike radial loads that act perpendicular to the shaft, overhung loads create torque and additional moment forces that strain shaft alignment and support structures. Properly accounting for overhung load in design and maintenance ensures optimal equipment reliability and minimizes the risk of costly downtime.

Calculating Radial and Overhung Loads

Calculating radial loads involves determining the force acting perpendicular to the shaft, typically caused by the weight of the rotating parts or misalignment, while overhung load calculations account for forces applied at a distance from the bearing support, creating bending moments. Radial load (Fr) is calculated using the formula Fr = F x cos(th), where F is the applied force and th is the angle relative to the shaft axis, whereas overhung load is assessed by multiplying the applied load by the distance from the bearing center to the point of load application (moment arm). Accurate calculation of these loads is crucial for selecting appropriate bearings and ensuring reliable performance in rotating machinery.

Common Applications: Where Radial and Overhung Loads Occur

Radial loads commonly occur in applications such as electric motors, gearboxes, and conveyor systems where forces act perpendicular to the shaft axis. Overhung loads are frequently seen in pump impellers, fan blades, and machine tool spindles where the load is applied at a distance from bearing supports. Understanding these load types helps optimize bearing selection and machine design for durability and performance.

Minimizing Load-Related Failures in Design

Radial loads act perpendicular to the shaft, evenly distributing forces across bearing surfaces, while overhung loads create bending moments that increase stress concentrations and accelerate wear, elevating the risk of premature failures. Minimizing load-related failures requires selecting bearings with adequate dynamic load ratings and optimizing shaft design to reduce bending moments caused by overhung loads. Proper alignment, use of support structures, and accurate load calculations ensure enhanced durability and reliability in mechanical systems.

Best Practices for Managing Radial and Overhung Loads

Effective management of radial and overhung loads requires precise bearing selection tailored to the specific load direction and magnitude, ensuring optimal durability and performance. Implementing proper shaft support and alignment minimizes deflection and uneven load distribution, reducing stress on bearings and extending machinery life. Regular inspection and lubrication schedules prevent premature wear caused by fluctuating loads, maintaining operational efficiency under varying radial and overhung load conditions.

Radial load Infographic

libterm.com

libterm.com