Portal cranes are essential for heavy lifting and material handling in ports and construction sites, offering precise control and high load capacities. These cranes facilitate efficient loading and unloading operations, improving workflow and reducing turnaround times. Discover how a portal crane can enhance your project's productivity by exploring the detailed uses and benefits in the full article.

Table of Comparison

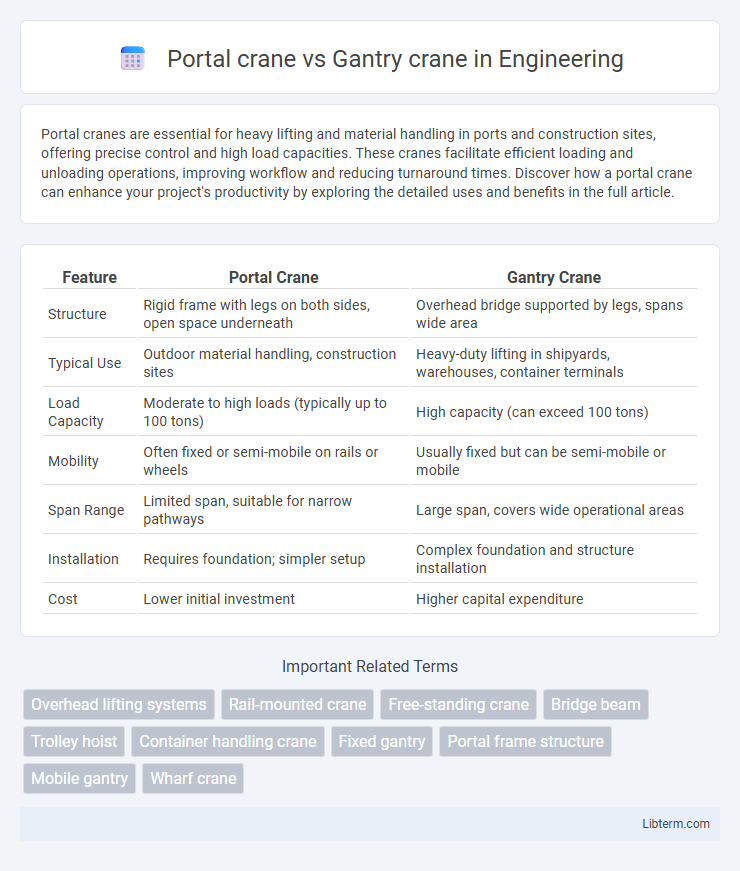

| Feature | Portal Crane | Gantry Crane |

|---|---|---|

| Structure | Rigid frame with legs on both sides, open space underneath | Overhead bridge supported by legs, spans wide area |

| Typical Use | Outdoor material handling, construction sites | Heavy-duty lifting in shipyards, warehouses, container terminals |

| Load Capacity | Moderate to high loads (typically up to 100 tons) | High capacity (can exceed 100 tons) |

| Mobility | Often fixed or semi-mobile on rails or wheels | Usually fixed but can be semi-mobile or mobile |

| Span Range | Limited span, suitable for narrow pathways | Large span, covers wide operational areas |

| Installation | Requires foundation; simpler setup | Complex foundation and structure installation |

| Cost | Lower initial investment | Higher capital expenditure |

Introduction: Portal Crane vs Gantry Crane

Portal cranes and gantry cranes are both types of overhead cranes used for heavy lifting, but they differ primarily in structure and application. Portal cranes feature a fixed overhead bridge supported by legs that run on tracks, often used in ports for container handling. Gantry cranes have a similar design but can be more mobile, with legs that may run on different types of rails or wheels, making them versatile for construction and industrial environments.

Definition and Basic Structure

A portal crane is a type of overhead crane featuring a horizontal beam supported by two vertical legs that move on fixed rails, designed mainly for loading and unloading heavy cargo in ports. A gantry crane shares a similar structure but can vary in size, often used in shipyards and manufacturing plants, typically comprising a bridge supported by two or more legs running on a track. Both cranes are essential for lifting and transporting heavy materials, with portal cranes optimized for outdoor use and gantry cranes providing flexibility in various industrial environments.

Key Differences in Design

Portal cranes feature a rigid frame supported by four legs, often mounted on rails for horizontal movement, enabling efficient handling of heavy loads in outdoor environments like ports and shipyards. Gantry cranes consist of a single bridge supported by two legs that move on rails, allowing flexibility in lifting operations across wide spans within industrial and manufacturing settings. The primary design distinction lies in the portal crane's fixed framework providing stability for heavy-duty tasks, while gantry cranes emphasize mobility and adaptability with their simpler, often mobile structure.

Advantages of Portal Cranes

Portal cranes offer superior mobility and flexibility compared to gantry cranes, allowing efficient movement of heavy loads across wider areas without fixed tracks. Their design enables easier installation and operation in port environments, reducing setup time and operational costs. Enhanced stability and load capacity make portal cranes ideal for handling large containers and bulky cargo in dynamic industrial settings.

Benefits of Gantry Cranes

Gantry cranes offer exceptional versatility and mobility, making them ideal for heavy lifting tasks in outdoor environments like shipyards and construction sites. Their robust design supports heavier loads and larger spans compared to portal cranes, enhancing operational efficiency. Maintenance is typically simpler and more cost-effective due to their modular structure, which reduces downtime and improves productivity.

Typical Applications and Industries

Portal cranes excel in container terminals and shipyards by efficiently handling heavy cargo and large containers. Gantry cranes are commonly utilized in rail yards and manufacturing plants for loading and unloading materials with precision. Both cranes serve critical roles in construction, logistics, and industrial sectors, optimizing material handling and operational workflows.

Load Capacities and Lifting Capabilities

Portal cranes typically offer load capacities ranging from 5 to 50 tons, making them suitable for medium to heavy lifting tasks in shipyards and construction sites. Gantry cranes, on the other hand, provide higher load capacities, often exceeding 100 tons, with advanced models capable of lifting up to 1,000 tons, ideal for large-scale industrial and container handling operations. The lifting capabilities of gantry cranes surpass portal cranes due to their robust design, longer spans, and greater height clearance, enabling them to handle heavier and bulkier loads efficiently.

Installation and Mobility Considerations

Portal cranes feature a fixed structure with a gantry supported by legs on rails, requiring permanent installation on specific sites, which provides stability but limits mobility. Gantry cranes, especially portable models, offer greater flexibility with wheeled bases or modular components allowing easier relocation and setup. Installation of portal cranes demands extensive groundwork and rail alignment, while gantry cranes require minimal foundation work, making them suitable for temporary or variable operational needs.

Maintenance and Operational Costs

Portal cranes generally incur lower maintenance costs than gantry cranes due to their simpler structural design and fewer moving parts. Operational expenses for portal cranes tend to be more economical as they require less energy and manpower for routine tasks, especially in lighter load scenarios. In contrast, gantry cranes, designed for heavier loads and larger spans, demand more frequent maintenance and higher operational costs, driven by their complex mechanisms and robust power systems.

Choosing the Right Crane for Your Project

Portal cranes and gantry cranes both serve crucial roles in heavy lifting but differ in structure and application. Portal cranes, featuring a fixed frame with a single or double girder supported by vertical legs, excel in loading docks and warehouses where space is limited. Gantry cranes, often larger and more versatile with a movable frame on wheels or tracks, are ideal for outdoor use in shipyards, construction sites, and large-scale manufacturing due to their ability to cover broader areas and handle heavier loads.

Portal crane Infographic

libterm.com

libterm.com