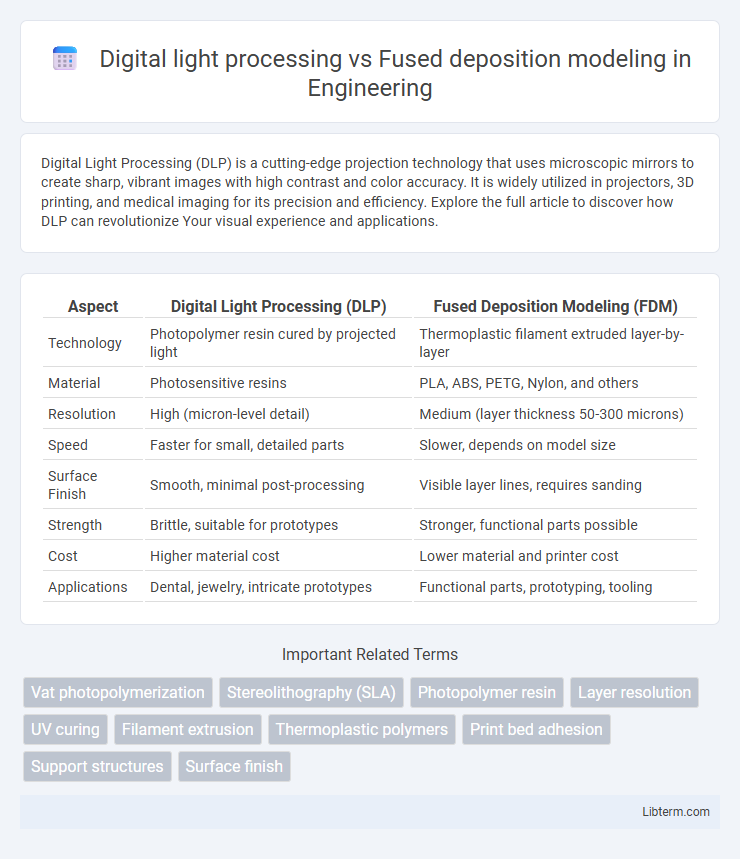

Digital Light Processing (DLP) is a cutting-edge projection technology that uses microscopic mirrors to create sharp, vibrant images with high contrast and color accuracy. It is widely utilized in projectors, 3D printing, and medical imaging for its precision and efficiency. Explore the full article to discover how DLP can revolutionize Your visual experience and applications.

Table of Comparison

| Aspect | Digital Light Processing (DLP) | Fused Deposition Modeling (FDM) |

|---|---|---|

| Technology | Photopolymer resin cured by projected light | Thermoplastic filament extruded layer-by-layer |

| Material | Photosensitive resins | PLA, ABS, PETG, Nylon, and others |

| Resolution | High (micron-level detail) | Medium (layer thickness 50-300 microns) |

| Speed | Faster for small, detailed parts | Slower, depends on model size |

| Surface Finish | Smooth, minimal post-processing | Visible layer lines, requires sanding |

| Strength | Brittle, suitable for prototypes | Stronger, functional parts possible |

| Cost | Higher material cost | Lower material and printer cost |

| Applications | Dental, jewelry, intricate prototypes | Functional parts, prototyping, tooling |

Introduction to Digital Light Processing (DLP) and Fused Deposition Modeling (FDM)

Digital Light Processing (DLP) leverages a digital projector screen to cure liquid resin layer by layer, enabling high-resolution and fast 3D printing ideal for detailed prototypes and dental models. Fused Deposition Modeling (FDM) extrudes thermoplastic filaments through a heated nozzle, depositing material layer by layer to create durable and functional parts suited for industrial and mechanical applications. Both technologies offer unique advantages in precision, speed, and material options, making them pivotal in additive manufacturing workflows.

Core Principles: How DLP and FDM 3D Printing Work

Digital Light Processing (DLP) 3D printing uses a digital projector to flash an entire layer of UV light onto a vat of photopolymer resin, curing it simultaneously to form solid layers with high precision. Fused Deposition Modeling (FDM) works by melting thermoplastic filament and extruding it through a heated nozzle, depositing material layer by layer to build the object from the bottom up. DLP excels in producing fine details and smooth surfaces due to its photopolymerization process, while FDM offers versatility and cost-effectiveness by melting and depositing heated material mechanically.

Material Compatibility: Resin vs Filament

Digital Light Processing (DLP) excels in high-resolution prints using photopolymer resins that cure under UV light, offering a wide variety of transparent, flexible, and castable resin options. In contrast, Fused Deposition Modeling (FDM) uses thermoplastic filaments such as PLA, ABS, and PETG, which provide greater mechanical strength and temperature resistance but lower detail compared to resin prints. Resin materials in DLP are ideal for intricate designs and smooth surface finishes, while filament materials in FDM are better suited for functional prototypes and durable parts.

Print Quality and Surface Finish Comparison

Digital Light Processing (DLP) offers superior print quality and surface finish due to its use of a high-resolution projector that cures resin with fine detail and smooth layers, ideal for intricate models and small features. Fused Deposition Modeling (FDM) produces parts with visible layer lines and a rougher surface finish caused by extruding melted filament in layers, which can result in lower precision and more post-processing. The photopolymer resin used in DLP provides a glossy, uniform surface, whereas FDM's thermoplastic materials often require sanding or acetone vapor smoothing for comparable aesthetics.

Speed and Efficiency in Production

Digital Light Processing (DLP) offers significantly faster print speeds compared to Fused Deposition Modeling (FDM) due to its ability to cure entire layers simultaneously using a digital light projector. This layer-by-layer curing process enhances production efficiency by reducing print time and improving surface resolution. Conversely, FDM builds objects layer by layer with a moving nozzle, resulting in slower print speeds and lower resolution, making DLP more suitable for rapid prototyping and high-detail applications.

Cost Analysis: Setup and Maintenance

Digital Light Processing (DLP) typically involves higher initial setup costs due to expensive projectors and resin materials but benefits from lower maintenance expenses with fewer moving parts. Fused Deposition Modeling (FDM) offers a more affordable entry point, relying on thermoplastic filaments and simpler hardware, though its maintenance can be higher because of frequent nozzle replacements and mechanical wear. Evaluating total cost of ownership reveals DLP's advantage in precision and speed at a premium, while FDM provides cost-effective versatility suitable for budget-conscious users.

Accuracy and Precision Differences

Digital Light Processing (DLP) offers superior accuracy and precision compared to Fused Deposition Modeling (FDM) due to its use of a digital projector to cure resin at a pixel level, achieving finer details and smoother surfaces. FDM relies on extruding thermoplastic filament layer by layer, which often results in visible layer lines and less precise dimension control. The resin-based technology in DLP minimizes layer thickness and offers better resolution, making it ideal for detailed prototypes and parts requiring tight tolerances.

Applications and Suitable Use Cases

Digital Light Processing (DLP) is ideal for producing highly detailed prototypes, dental molds, and jewelry due to its precision and smooth surface finish, making it suitable for applications requiring fine resolution and complex geometries. Fused Deposition Modeling (FDM) excels in creating functional parts, durable components, and large-scale prototypes, widely used in automotive, aerospace, and industrial manufacturing because of its cost-effectiveness and material versatility. Businesses prioritize DLP for intricate design validation while choosing FDM for rapid production and end-use parts in robust materials like ABS and PLA.

Pros and Cons of DLP and FDM Technologies

Digital Light Processing (DLP) offers high-resolution prints with smooth surface finishes, ideal for detailed prototypes and intricate designs, but it requires expensive resins and post-processing steps that can increase production time. Fused Deposition Modeling (FDM) provides cost-effective, durable parts suitable for functional prototypes and end-use applications, though it typically delivers lower resolution and visible layer lines compared to DLP. While DLP excels in precision and aesthetic quality, FDM is favored for affordability and material versatility, making the choice dependent on the specific needs of the project.

Choosing the Right Technology for Your Project

Digital Light Processing (DLP) offers high-resolution prints with smooth surface finishes ideal for intricate designs and rapid prototyping, while Fused Deposition Modeling (FDM) excels in producing durable, functional parts with cost-effective materials like PLA and ABS. Selecting the right technology depends on project requirements such as detail precision, material properties, production speed, and budget constraints. For fine-detail, low-volume applications, DLP is preferred, whereas FDM suits larger, more robust parts where strength and affordability are critical.

Digital light processing Infographic

libterm.com

libterm.com