Radiographic testing uses X-rays or gamma rays to inspect the internal structure of materials and detect hidden defects without causing damage. This nondestructive testing method is essential for ensuring the safety and integrity of critical components in industries such as aerospace, construction, and manufacturing. Discover how radiographic testing can enhance your quality control processes by exploring the rest of this article.

Table of Comparison

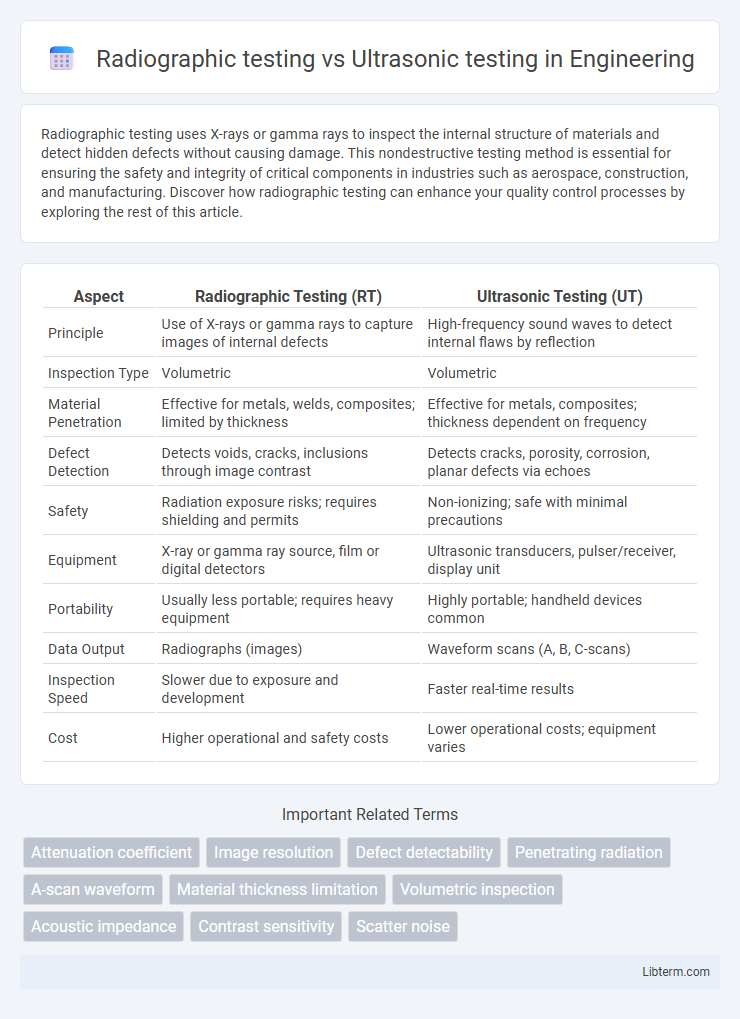

| Aspect | Radiographic Testing (RT) | Ultrasonic Testing (UT) |

|---|---|---|

| Principle | Use of X-rays or gamma rays to capture images of internal defects | High-frequency sound waves to detect internal flaws by reflection |

| Inspection Type | Volumetric | Volumetric |

| Material Penetration | Effective for metals, welds, composites; limited by thickness | Effective for metals, composites; thickness dependent on frequency |

| Defect Detection | Detects voids, cracks, inclusions through image contrast | Detects cracks, porosity, corrosion, planar defects via echoes |

| Safety | Radiation exposure risks; requires shielding and permits | Non-ionizing; safe with minimal precautions |

| Equipment | X-ray or gamma ray source, film or digital detectors | Ultrasonic transducers, pulser/receiver, display unit |

| Portability | Usually less portable; requires heavy equipment | Highly portable; handheld devices common |

| Data Output | Radiographs (images) | Waveform scans (A, B, C-scans) |

| Inspection Speed | Slower due to exposure and development | Faster real-time results |

| Cost | Higher operational and safety costs | Lower operational costs; equipment varies |

Introduction to Non-Destructive Testing Methods

Radiographic testing uses X-rays or gamma rays to create images of a material's interior, detecting flaws such as cracks or voids without damaging the sample. Ultrasonic testing employs high-frequency sound waves to identify discontinuities and measure material thickness by analyzing wave reflections. Both are essential non-destructive testing methods widely used in industries like aerospace, manufacturing, and construction for ensuring structural integrity and safety.

Overview of Radiographic Testing

Radiographic testing (RT) utilizes X-rays or gamma rays to create detailed images of an object's internal structure, revealing flaws such as cracks, voids, and inclusions. This non-destructive testing method is highly effective for inspecting welds, castings, and machined parts in industries like aerospace, automotive, and construction. Radiographic testing provides permanent visual records, allowing precise defect sizing and enhancing quality control in manufacturing and maintenance processes.

Overview of Ultrasonic Testing

Ultrasonic testing (UT) uses high-frequency sound waves to detect internal flaws or characterize materials, offering precise depth measurement and real-time results. Unlike radiographic testing, UT avoids radiation exposure and provides immediate feedback without film processing. Commonly applied in weld inspections and corrosion thickness measurements, ultrasonic testing enhances safety and efficiency in nondestructive testing (NDT) practices.

Key Principles: Radiographic vs Ultrasonic Testing

Radiographic testing (RT) uses X-rays or gamma rays to create images of internal structures by capturing the differential absorption of radiation through materials, revealing defects as variations in film density. Ultrasonic testing (UT) employs high-frequency sound waves transmitted into the material, detecting flaws by measuring the reflection or attenuation of echoes from internal discontinuities. RT excels in visualizing through-thickness defects with image interpretation, while UT provides precise depth and characterization of flaws without radiation exposure.

Advantages of Radiographic Testing

Radiographic testing offers superior detection of internal defects, providing clear, permanent images that can be reviewed and archived for future examination. It is highly effective for inspecting complex geometries and thickness variations in metals and welds, ensuring accurate quality assessment. Radiographic testing also excels in detecting volumetric flaws, such as porosity and inclusions, which are critical for maintaining structural integrity.

Advantages of Ultrasonic Testing

Ultrasonic testing offers superior sensitivity in detecting internal flaws, including very small cracks and inclusions, which might be missed by radiographic testing. It provides immediate results without the need for hazardous radiation, ensuring safer working conditions and environmental compliance. Furthermore, ultrasonic testing is portable and can inspect complex geometries and thicker materials more effectively than radiographic methods.

Limitations and Disadvantages of Each Method

Radiographic testing (RT) is limited by its inability to detect planar defects effectively and requires access to both sides of the component, posing safety hazards due to radiation exposure. Ultrasonic testing (UT) faces challenges with complex geometries and coarse-grained materials that can scatter sound waves, reducing flaw detection sensitivity. RT also involves longer processing times and higher costs compared to UT, while UT requires skilled operators to interpret signal data accurately, increasing the likelihood of human error.

Typical Applications and Use Cases

Radiographic testing (RT) is widely used in inspecting welds, castings, and structural components in industries such as aerospace, petrochemical, and construction, due to its ability to reveal internal defects like cracks, porosity, and inclusions. Ultrasonic testing (UT) is preferred for thickness measurements, corrosion mapping, and flaw detection in metals and composites, commonly applied in power plants, pipelines, and manufacturing for real-time, high-resolution inspection. Both methods are essential for ensuring material integrity, with RT excelling in volumetric defect identification and UT providing versatile, portable solutions for on-site inspections.

Safety Considerations and Regulations

Radiographic testing (RT) involves exposure to ionizing radiation, necessitating strict adherence to safety regulations such as those set by OSHA and the Nuclear Regulatory Commission to protect operators and the environment from harmful exposure. Ultrasonic testing (UT) utilizes high-frequency sound waves, posing minimal health risks and often subject to less stringent safety regulations, though operators must still follow guidelines to prevent equipment-related injuries. Both methods require compliance with industry standards like ASNT and ISO to ensure safe practices and accurate inspection results.

Choosing the Right Testing Method

Radiographic testing (RT) excels in detecting internal flaws such as porosity and inclusions within metal welds using X-rays or gamma rays, ideal for examining complex geometries and thick materials. Ultrasonic testing (UT) offers precise flaw sizing and depth measurement by transmitting high-frequency sound waves, making it suitable for inspecting thin materials and components with limited access. Selecting the right method depends on factors like material type, part thickness, defect type, inspection speed, and safety considerations, with RT favored for detailed volumetric evaluation and UT preferred for rapid, portable inspections.

Radiographic testing Infographic

libterm.com

libterm.com