Direct metal laser sintering (DMLS) is an advanced additive manufacturing technique that uses a high-powered laser to fuse fine metal powders layer by layer, creating durable and complex metal parts with exceptional precision. This process offers unmatched design flexibility and mechanical strength, making it ideal for aerospace, automotive, and medical applications. Explore the rest of the article to discover how DMLS can transform your manufacturing projects.

Table of Comparison

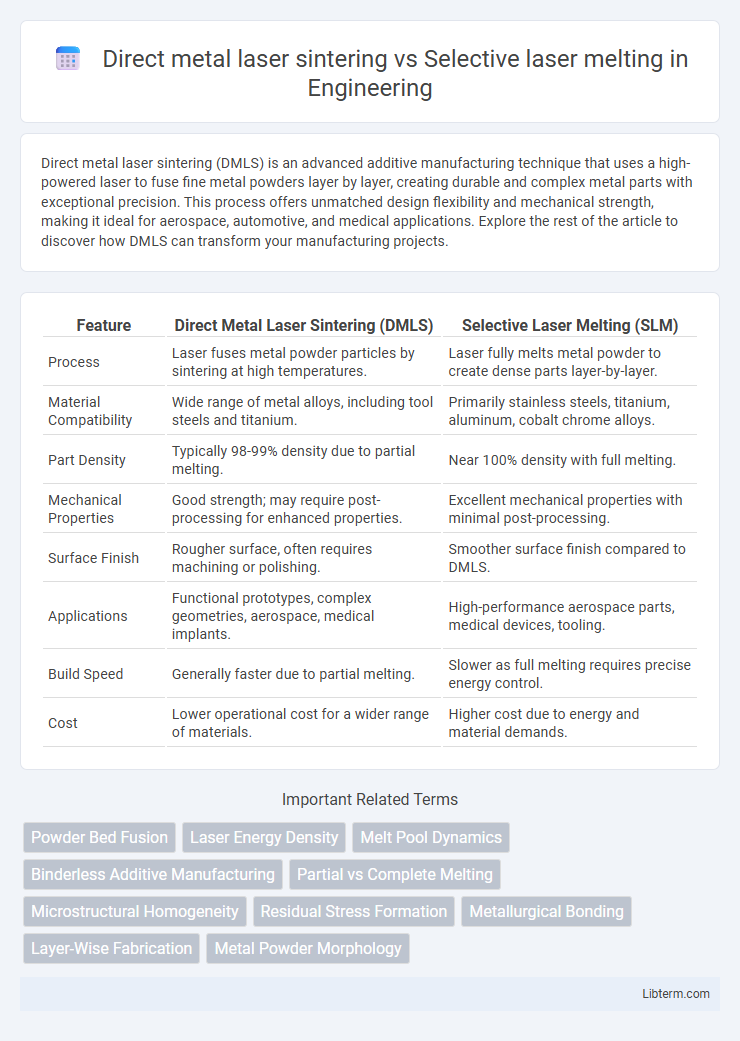

| Feature | Direct Metal Laser Sintering (DMLS) | Selective Laser Melting (SLM) |

|---|---|---|

| Process | Laser fuses metal powder particles by sintering at high temperatures. | Laser fully melts metal powder to create dense parts layer-by-layer. |

| Material Compatibility | Wide range of metal alloys, including tool steels and titanium. | Primarily stainless steels, titanium, aluminum, cobalt chrome alloys. |

| Part Density | Typically 98-99% density due to partial melting. | Near 100% density with full melting. |

| Mechanical Properties | Good strength; may require post-processing for enhanced properties. | Excellent mechanical properties with minimal post-processing. |

| Surface Finish | Rougher surface, often requires machining or polishing. | Smoother surface finish compared to DMLS. |

| Applications | Functional prototypes, complex geometries, aerospace, medical implants. | High-performance aerospace parts, medical devices, tooling. |

| Build Speed | Generally faster due to partial melting. | Slower as full melting requires precise energy control. |

| Cost | Lower operational cost for a wider range of materials. | Higher cost due to energy and material demands. |

Introduction to Metal Additive Manufacturing

Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are advanced metal additive manufacturing processes that build parts layer by layer using high-powered lasers to fuse powdered metal. DMLS partially melts metal powders typically composed of alloyed materials, resulting in components with slightly porous microstructures ideal for complex geometries and functional prototypes. SLM fully melts pure metal powders, yielding fully dense and high-strength parts suitable for aerospace, automotive, and medical applications requiring superior mechanical properties.

Overview of Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an additive manufacturing technique that uses a high-powered laser to fuse metal powder particles layer by layer, creating complex and precise metal parts. Unlike Selective Laser Melting (SLM), which fully melts the powder, DMLS sinters the particles just below their melting point, resulting in slightly different microstructural properties and mechanical behavior. DMLS is commonly used for producing functional prototypes, customized medical implants, and aerospace components due to its high accuracy and ability to work with a variety of metal alloys.

Overview of Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is an additive manufacturing technique that uses a high-power laser to fully melt fine metal powders, creating dense and complex 3D metal parts layer by layer. Unlike Direct Metal Laser Sintering (DMLS), which typically sinters powder particles without complete melting, SLM achieves superior mechanical properties and structural integrity by ensuring full fusion of the metal powder. Common materials used in SLM include titanium alloys, stainless steel, and aluminum, making it ideal for aerospace, automotive, and medical industries requiring high-performance metal components.

Technical Differences Between DMLS and SLM

Direct Metal Laser Sintering (DMLS) fuses metal powders below their melting point using a laser, creating parts through partial melting and solid-state sintering, while Selective Laser Melting (SLM) fully melts metal powders to form a homogeneous solid. DMLS typically uses alloys tailored for sintering, resulting in parts with slightly different microstructures compared to SLM, which produces denser parts due to complete melting. The technical distinction lies in energy input and process parameters, with SLM requiring higher laser power and precise control to achieve full melting and minimize porosity.

Material Compatibility and Selection

Direct metal laser sintering (DMLS) supports a broader range of materials, including various metal alloys such as titanium, aluminum, and cobalt-chrome, enabling complex geometries with high strength. Selective laser melting (SLM) typically uses fully dense metal powders like stainless steel, aluminum, and titanium, providing superior mechanical properties and structural integrity due to complete melting. Material selection in DMLS often prioritizes cost-effectiveness and design flexibility, while SLM emphasizes high-performance applications requiring maximum density and mechanical strength.

Part Quality and Mechanical Properties

Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) both produce high-quality metal parts, but SLM typically offers superior part density and mechanical properties due to full melting of powder particles. DMLS parts may exhibit slightly higher porosity and anisotropy, impacting tensile strength and fatigue resistance compared to SLM. Both technologies enable complex geometries, but SLM is preferred for applications requiring optimal strength, durability, and isotropic mechanical performance.

Applications in Various Industries

Direct Metal Laser Sintering (DMLS) is widely used in aerospace for creating lightweight, complex components with excellent mechanical properties, while Selective Laser Melting (SLM) finds significant application in the medical industry for producing biocompatible implants with high density and precision. Automotive industries leverage DMLS for rapid prototyping and functional parts, whereas SLM is preferred for end-use parts requiring superior metallurgical quality and structural integrity. Both technologies enable production in tooling, jewelry, and energy sectors, but SLM's fully melted parts often meet stricter performance standards in critical applications.

Cost Considerations and Efficiency

Direct Metal Laser Sintering (DMLS) generally incurs lower equipment costs and consumes less energy compared to Selective Laser Melting (SLM), making it more cost-effective for small to medium production runs. SLM requires higher laser power and more stringent process controls to achieve full melting, resulting in longer build times and increased operational expenses that are justified when manufacturing parts demanding superior density and mechanical properties. Efficiency in DMLS is often higher due to faster layer deposition rates and less complex process parameters, enhancing throughput for geometrically intricate components.

Challenges and Limitations of DMLS vs SLM

Direct Metal Laser Sintering (DMLS) faces challenges such as partially melted powder particles that can cause lower density and reduced mechanical properties compared to Selective Laser Melting (SLM), which achieves full melting and better material homogeneity. DMLS often results in higher surface roughness and requires more post-processing to meet stringent tolerance requirements, while SLM's complete melting typically produces parts with finer resolution and less porosity. However, SLM systems are generally more expensive and complex, limiting accessibility despite their superior part quality over the DMLS process.

Future Trends in Metal 3D Printing Technologies

Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) both drive advancements in metal 3D printing, with future trends emphasizing faster build speeds, improved surface finish, and enhanced material properties through hybrid processes and AI-driven parameter optimization. Emerging developments highlight multi-laser systems and real-time process monitoring to increase production scalability and quality control. These innovations aim to expand the application scope towards complex aerospace, automotive, and biomedical components requiring high precision and functional performance.

Direct metal laser sintering Infographic

libterm.com

libterm.com