Following a clear instruction list enhances productivity and reduces errors in any task you undertake. Prioritizing steps and maintaining focus ensures efficient completion of your projects. Explore the rest of the article to master the art of creating and utilizing effective instruction lists.

Table of Comparison

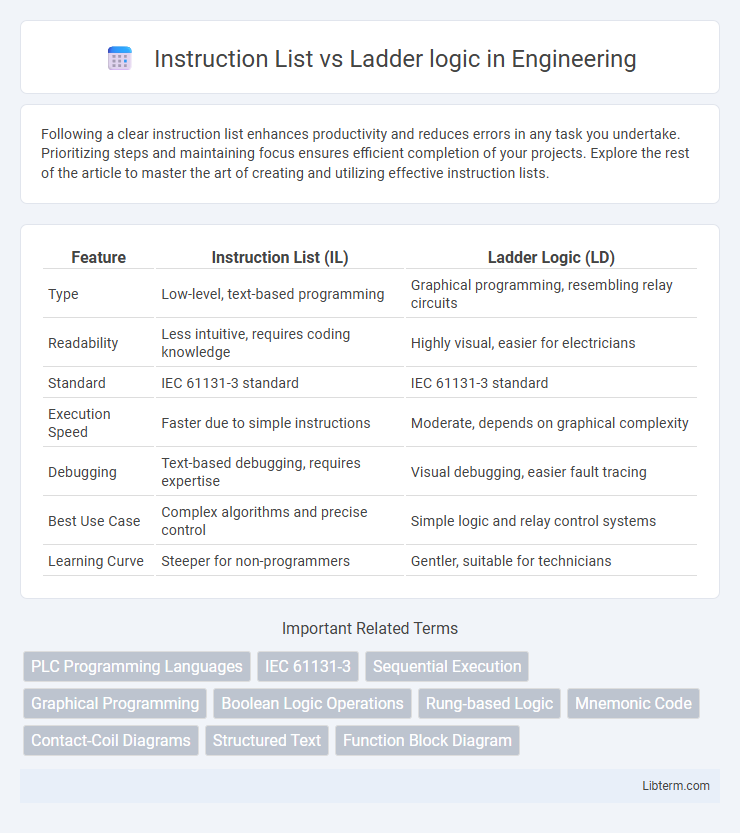

| Feature | Instruction List (IL) | Ladder Logic (LD) |

|---|---|---|

| Type | Low-level, text-based programming | Graphical programming, resembling relay circuits |

| Readability | Less intuitive, requires coding knowledge | Highly visual, easier for electricians |

| Standard | IEC 61131-3 standard | IEC 61131-3 standard |

| Execution Speed | Faster due to simple instructions | Moderate, depends on graphical complexity |

| Debugging | Text-based debugging, requires expertise | Visual debugging, easier fault tracing |

| Best Use Case | Complex algorithms and precise control | Simple logic and relay control systems |

| Learning Curve | Steeper for non-programmers | Gentler, suitable for technicians |

Introduction to PLC Programming Languages

Instruction List (IL) and Ladder Logic (LD) are fundamental PLC programming languages used to control automation processes. IL operates through low-level, text-based commands resembling assembly language, enabling precise and compact coding ideal for complex instructions. Ladder Logic visually represents control circuits with relay logic symbols, making it intuitive for electricians and engineers to design and troubleshoot industrial automation systems.

Overview of Instruction List (IL)

Instruction List (IL) is a low-level programming language used in programmable logic controllers (PLCs), designed for efficient, compact coding. It consists of mnemonic codes that represent basic operations such as load, store, and jump, making it suitable for simple control tasks. IL allows precise control over hardware actions, providing faster execution compared to graphical languages like Ladder Logic.

Overview of Ladder Logic (LD)

Ladder Logic (LD) is a graphical programming language used extensively in programmable logic controllers (PLCs) for industrial automation, representing control processes through relay logic diagrams. It employs a visual format resembling electrical circuits, using symbols like contacts and coils to emulate physical relay logic, making it intuitive for electricians and engineers. Ladder Logic enables straightforward debugging and real-time monitoring, facilitating the design of complex control sequences through visually structured rungs and parallel branches.

Syntax and Structure Comparison

Instruction List (IL) uses low-level, text-based syntax composed of mnemonic codes representing individual operations, which makes it concise but less visually intuitive. Ladder Logic (LD) employs a graphical structure resembling electrical relay diagrams with symbols representing contacts and coils, enhancing readability and ease of troubleshooting. IL's linear command sequence contrasts with LD's parallel rung arrangement, reflecting fundamental differences in programming style and user interaction.

Programming Efficiency and Speed

Instruction List (IL) programming offers concise coding with low-level commands, enhancing programming efficiency for experienced users by enabling precise control and faster execution on PLCs. Ladder Logic (LD) provides a visual and intuitive interface that simplifies troubleshooting and development, though it may require more lines of code, potentially reducing execution speed compared to IL. Choosing between IL and LD depends on the complexity of the control task, programmer expertise, and the priority between rapid code development and execution speed.

Readability and Debugging

Instruction List (IL) offers a low-level, assembly-like syntax that can be challenging to read and understand quickly, potentially slowing down debugging efforts. Ladder Logic (LD) features a graphical representation resembling electrical relay diagrams, enhancing readability and making it easier for engineers and technicians to diagnose and correct faults visually. LD's intuitive layout supports faster debugging by clearly illustrating control flow, whereas IL's textual format demands deeper familiarity with specific instructions and addresses.

Application Suitability

Instruction List offers precise control for complex arithmetic and data manipulation tasks, making it suitable for low-level programming in industrial automation requiring detailed instructions. Ladder Logic excels in visually representing control processes, ideal for applications involving relay logic and simple on/off control, commonly used in manufacturing and process industries. Choosing between Instruction List and Ladder Logic depends on the application's complexity and the programmer's preference for textual versus graphical programming environments.

Hardware and Software Support

Instruction List (IL) and Ladder Logic (LD) serve distinct roles in programmable logic controller (PLC) programming, with IL offering low-level, text-based coding suitable for detailed hardware manipulation and compact memory usage, ideal for resource-constrained PLCs. Ladder Logic provides a graphical interface resembling electrical relay circuits, enhancing ease of programming and troubleshooting, widely supported across diverse PLC manufacturers and compatible with sophisticated simulation software. Hardware support for Ladder Logic is extensive in modern industrial automation systems, while Instruction List remains favored in legacy systems requiring minimal processor overhead and direct control over hardware operations.

Industry Adoption Trends

Instruction List (IL) and Ladder Logic (LD) are both prominent programming languages in industrial automation, but Ladder Logic has seen wider adoption due to its graphical nature and ease of use for electricians and technicians. Industry trends show a growing preference for Ladder Logic in complex control systems, supported by extensive vendor toolkits and standardized frameworks like IEC 61131-3. Instruction List, being low-level and text-based, is gradually declining in popularity as industries prioritize intuitive visualization and maintainability in Programmable Logic Controller (PLC) programming.

Choosing the Right Language for Your Project

Instruction List (IL) offers a low-level, compact approach ideal for simple, sequential tasks requiring precise control, while Ladder Logic (LD) excels in visualizing complex relay-based circuits and is widely favored in industrial automation for its intuitiveness. Choosing the right language depends on project complexity, maintenance requirements, and programmer expertise; IL suits experienced programmers needing efficiency, whereas LD benefits teams prioritizing readability and ease of troubleshooting. Evaluating factors like hardware compatibility, scalability, and debugging tools ensures optimal performance and longevity for automated systems.

Instruction List Infographic

libterm.com

libterm.com