Roller bearings are designed to reduce friction and support radial and axial loads in rotating machinery, enhancing efficiency and longevity. Their precise construction allows for smooth motion under heavy loads, making them essential in automotive, industrial, and aerospace applications. Discover how choosing the right roller bearing can optimize your machinery's performance by reading the full article.

Table of Comparison

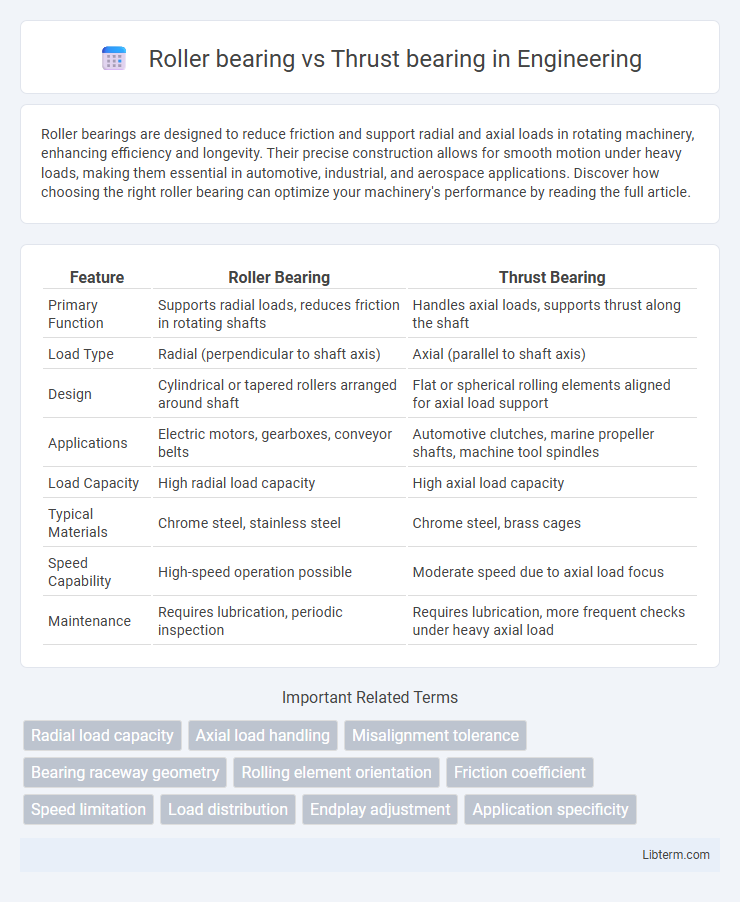

| Feature | Roller Bearing | Thrust Bearing |

|---|---|---|

| Primary Function | Supports radial loads, reduces friction in rotating shafts | Handles axial loads, supports thrust along the shaft |

| Load Type | Radial (perpendicular to shaft axis) | Axial (parallel to shaft axis) |

| Design | Cylindrical or tapered rollers arranged around shaft | Flat or spherical rolling elements aligned for axial load support |

| Applications | Electric motors, gearboxes, conveyor belts | Automotive clutches, marine propeller shafts, machine tool spindles |

| Load Capacity | High radial load capacity | High axial load capacity |

| Typical Materials | Chrome steel, stainless steel | Chrome steel, brass cages |

| Speed Capability | High-speed operation possible | Moderate speed due to axial load focus |

| Maintenance | Requires lubrication, periodic inspection | Requires lubrication, more frequent checks under heavy axial load |

Introduction to Roller Bearings and Thrust Bearings

Roller bearings use cylindrical or tapered rolling elements to support radial loads and reduce friction between rotating parts, making them ideal for applications requiring high load capacity and durability. Thrust bearings, designed to handle axial loads, feature flat or tapered rolling elements that enable smooth rotational movement while supporting forces parallel to the shaft axis. Both bearing types optimize mechanical performance but serve distinct roles depending on load direction and machine design.

Key Differences in Design and Function

Roller bearings use cylindrical or tapered rolling elements designed to support radial loads with low friction, whereas thrust bearings feature axial rolling elements optimized to accommodate axial forces in rotating shafts. Roller bearings typically have a higher load capacity for radial loads and are suited for heavy-duty applications, while thrust bearings are engineered to manage axial thrusts, often found in automotive or aerospace assemblies. The design distinctions lie in the orientation and shape of the rolling elements, impacting their load distribution and specific functional roles within machinery.

Load Handling Capabilities

Roller bearings excel in handling radial loads due to their cylindrical rolling elements that distribute pressure over a larger area, which reduces friction and wear. Thrust bearings are specifically designed to manage axial loads, supporting forces parallel to the shaft and preventing movement along the axis. Selecting the appropriate bearing depends on whether the application requires managing radial forces or axial forces for optimal load handling performance.

Applications of Roller Bearings

Roller bearings excel in applications requiring high radial load capacity and durability, such as conveyor systems, electric motors, and heavy machinery. They are preferred in industries like automotive, mining, and industrial equipment due to their ability to handle heavy loads and reduce friction. Unlike thrust bearings, roller bearings are optimized for supporting radial loads rather than axial forces.

Applications of Thrust Bearings

Thrust bearings are primarily used in applications where axial loads must be supported, such as in automotive transmissions, marine propeller shafts, and machine tool spindles. These bearings enable smooth rotation while handling heavy axial forces, making them essential for rotary equipment that experiences significant thrust loads. Compared to roller bearings, thrust bearings are specifically designed to accommodate high axial pressure in confined spaces, ensuring durability and precision in industrial machinery.

Durability and Lifespan Comparison

Roller bearings exhibit enhanced durability due to their ability to distribute load over a larger surface area, reducing stress and wear compared to thrust bearings. Thrust bearings, designed primarily to handle axial loads, often face higher wear rates under heavy or misaligned loads, leading to shorter lifespans in demanding applications. Maintenance intervals and material quality also significantly influence the lifespan of both bearing types, with roller bearings generally outperforming thrust bearings in high-load, high-speed environments.

Maintenance and Lubrication Needs

Roller bearings require regular lubrication with high-quality grease or oil to minimize friction and prevent wear, and they often benefit from periodic cleaning to remove contaminants. Thrust bearings demand precise lubrication to handle axial loads effectively, with oil-based lubricants commonly preferred to maintain the bearing surface and avoid overheating. Maintenance schedules for thrust bearings are typically more rigorous due to their critical role in axial positioning and load management in machinery.

Cost Considerations and ROI

Roller bearings generally have a higher initial cost due to their design complexity and material requirements but offer a longer lifespan and reduced maintenance, leading to better ROI in heavy-load applications. Thrust bearings tend to be more cost-effective upfront, especially for axial load support, but may incur higher replacement and downtime costs if subjected to improper loading conditions. Evaluating total cost of ownership, including installation, maintenance, and durability, is crucial for an accurate ROI comparison between roller and thrust bearings.

Performance in High-Speed Operations

Roller bearings exhibit superior performance in high-speed operations due to their low friction and ability to distribute loads evenly, minimizing heat generation and wear. Thrust bearings, designed primarily for axial loads, tend to have limitations in speed capabilities because of higher friction and heat buildup under high rotational velocities. Selecting roller bearings for applications involving rapid rotational speeds ensures enhanced durability and operational efficiency.

Choosing the Right Bearing for Your Application

Choosing the right bearing for your application requires understanding the load direction and motion type; roller bearings excel in handling radial loads with high speed and heavy loads, while thrust bearings are specifically designed to support axial loads. Consider factors such as load capacity, operating speed, alignment requirements, and the environment to optimize performance and longevity. Selecting the correct bearing type ensures efficient operation, reduces maintenance costs, and prevents premature failure in mechanical systems.

Roller bearing Infographic

libterm.com

libterm.com