A dedendum circle defines the boundary where the gear tooth root ends and the gear blank begins, playing a crucial role in gear design and ensuring proper meshing of gears. It determines the depth of the gear tooth below the pitch circle and prevents interference between mating gears. Explore this article to understand how the dedendum circle impacts gear performance and durability in your mechanical systems.

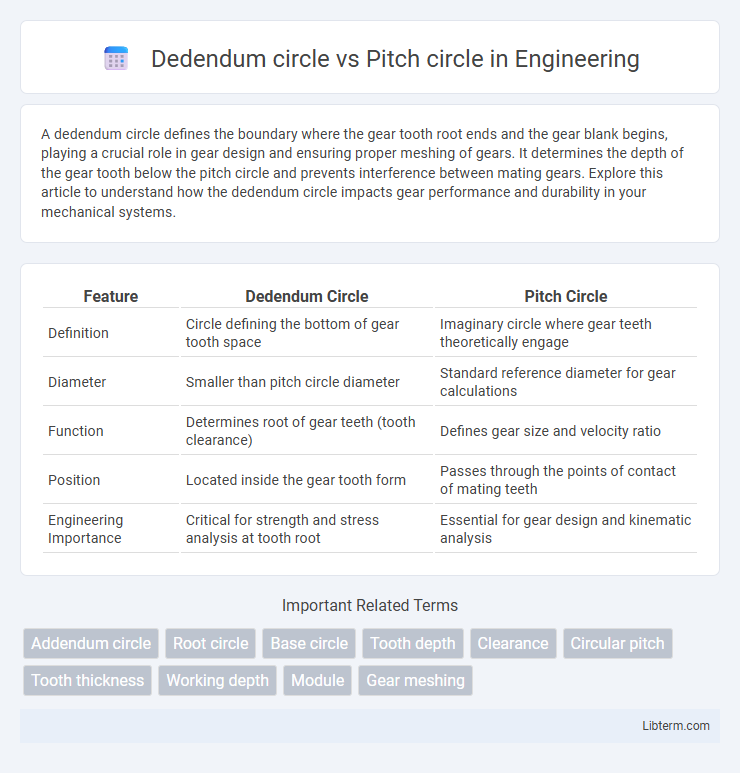

Table of Comparison

| Feature | Dedendum Circle | Pitch Circle |

|---|---|---|

| Definition | Circle defining the bottom of gear tooth space | Imaginary circle where gear teeth theoretically engage |

| Diameter | Smaller than pitch circle diameter | Standard reference diameter for gear calculations |

| Function | Determines root of gear teeth (tooth clearance) | Defines gear size and velocity ratio |

| Position | Located inside the gear tooth form | Passes through the points of contact of mating teeth |

| Engineering Importance | Critical for strength and stress analysis at tooth root | Essential for gear design and kinematic analysis |

Introduction to Gear Terminology

The dedendum circle in gear terminology refers to the imaginary circle that marks the bottom of the tooth space or the root of the gear tooth, defining the depth of the tooth below the pitch circle. The pitch circle is a critical gear parameter representing the theoretical circle where two gears effectively mesh and transmit motion without slipping, determining the gear ratio and velocity. Understanding the distinction between the dedendum and pitch circles is essential for analyzing gear tooth geometry, ensuring proper clearance, and preventing interference during gear operation.

What is the Pitch Circle?

The pitch circle is an imaginary circle that passes through the points where gear teeth of meshing gears effectively contact and transfer motion. It serves as the reference circle for defining key gear dimensions such as module, number of teeth, and pitch diameter. The dedendum circle lies below the pitch circle and defines the root diameter, marking the lowest point of the tooth space.

Understanding the Dedendum Circle

The dedendum circle is the imaginary circle that marks the bottom of the gear teeth and lies below the pitch circle, defining the depth of the gear tooth space. Understanding the dedendum circle is crucial for calculating the root diameter, which affects gear strength and meshing efficiency. While the pitch circle represents the effective contact point of gears, the dedendum circle ensures proper clearance and prevents interference between mating gear teeth.

Key Differences Between Dedendum Circle and Pitch Circle

The dedendum circle is the circle that defines the bottom of the gear tooth space, while the pitch circle represents the theoretical circle where gear teeth effectively engage without slipping. The pitch circle is fundamental for calculating gear ratios and transmitting motion, whereas the dedendum circle determines the clearance and root diameter of the gear. Key differences include their roles in gear design: the pitch circle is used for kinematic purposes, and the dedendum circle ensures proper tooth clearance and prevents interference.

Importance of the Pitch Circle in Gear Design

The pitch circle is crucial in gear design as it defines the size and spacing of gears, ensuring accurate meshing and transmission of motion. Unlike the dedendum circle, which marks the depth of gear teeth below the pitch line, the pitch circle determines the gear's effective radius for calculating speed ratios and torque transfer. Correctly designing the pitch circle directly impacts gear efficiency, load distribution, and overall performance in mechanical systems.

Role of Dedendum Circle in Gear Functionality

The dedendum circle defines the root diameter of a gear, marking the base where gear teeth are cut and allowing adequate clearance for the mating gear's tooth tip. Its precise dimension is critical for ensuring smooth engagement and preventing interference between teeth during rotation. By setting the lower boundary of the gear tooth, the dedendum circle influences load distribution and the overall durability of the gear mechanism.

Impact on Gear Meshing and Performance

The dedendum circle, defined by the root diameter, determines the clearance below the pitch circle, directly affecting gear tooth engagement and preventing interference during meshing. The pitch circle serves as the theoretical contact line where gears transmit motion and power efficiently, ensuring proper alignment and load distribution. Variations between dedendum and pitch circles impact the smoothness of gear operation, noise levels, and overall durability of the gear system.

Measurement and Calculation Methods

The pitch circle is defined by the diameter where the teeth of gears effectively engage, calculated using the number of teeth divided by the diametral pitch or module; measurement involves precise gear tooth counting and diameter assessment through calipers or specialized gear measurement tools. The dedendum circle, located below the pitch circle, corresponds to the root diameter of the gear teeth and is derived by subtracting the dedendum (usually 1.25 times the module) from the pitch radius; measurement requires identifying the bottom land of the gear teeth and using depth gauges or coordinate measuring machines for accuracy. Both circles are critical in gear design, ensuring proper meshing and load distribution through accurate dimensional analysis based on gear geometry standards.

Common Misconceptions and Clarifications

The dedendum circle represents the base diameter of the gear tooth below the pitch circle, defining the root of the tooth, while the pitch circle is the theoretical circle where gears effectively mesh and transmit motion. A common misconception is that the dedendum circle and pitch circle are the same or interchangeable, but the dedendum circle is always smaller in diameter and crucial for clearance and avoiding interference. Clarifying their distinct roles ensures accurate gear design, with the pitch circle determining gear ratio and the dedendum circle affecting tooth strength and engagement.

Conclusion: Choosing the Right Reference Circle

Choosing the right reference circle between the dedendum circle and pitch circle depends on the specific gear design and analysis requirements. The pitch circle serves as the primary reference for defining gear dimensions, tooth geometry, and velocity ratios, making it essential for general gear calculations. The dedendum circle is critical for ensuring proper clearance and avoiding interference, particularly in detailed tooth contact analysis and manufacturing processes.

Dedendum circle Infographic

libterm.com

libterm.com