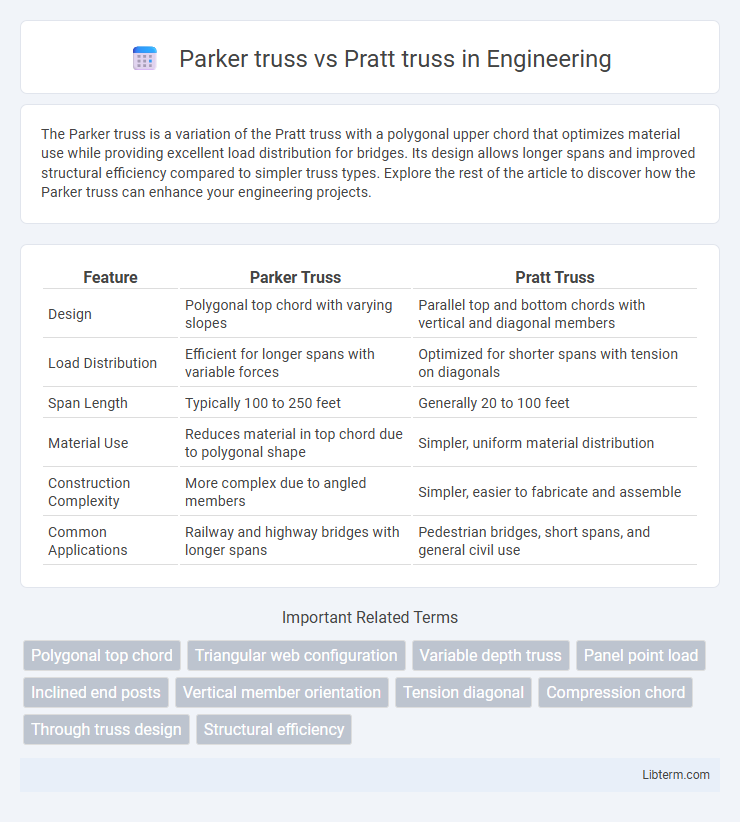

The Parker truss is a variation of the Pratt truss with a polygonal upper chord that optimizes material use while providing excellent load distribution for bridges. Its design allows longer spans and improved structural efficiency compared to simpler truss types. Explore the rest of the article to discover how the Parker truss can enhance your engineering projects.

Table of Comparison

| Feature | Parker Truss | Pratt Truss |

|---|---|---|

| Design | Polygonal top chord with varying slopes | Parallel top and bottom chords with vertical and diagonal members |

| Load Distribution | Efficient for longer spans with variable forces | Optimized for shorter spans with tension on diagonals |

| Span Length | Typically 100 to 250 feet | Generally 20 to 100 feet |

| Material Use | Reduces material in top chord due to polygonal shape | Simpler, uniform material distribution |

| Construction Complexity | More complex due to angled members | Simpler, easier to fabricate and assemble |

| Common Applications | Railway and highway bridges with longer spans | Pedestrian bridges, short spans, and general civil use |

Introduction to Parker and Pratt Trusses

Parker truss bridges feature a polygonal top chord that reduces the length and weight of members compared to the straight top chord of Pratt trusses, which have a design with vertical compression members and diagonal tension members slanting towards the center. The Parker truss is a variation of the Pratt truss, optimized for longer spans by adjusting the shape of the top chord to improve distribution of forces. Both trusses are widely used in bridge engineering for their efficiency in handling loads, with the Pratt truss favored for its simplicity and the Parker truss preferred for increased span lengths.

Historical Background: Parker vs Pratt Truss

The Pratt truss, patented in 1844 by Thomas and Caleb Pratt, became widely popular in the late 19th century due to its efficient use of materials and ease of construction, primarily designed for railroad bridges. The Parker truss, a variation of the Pratt truss developed by Charles H. Parker in the 1870s, introduced a polygonal top chord to reduce the length and weight of compression members, enhancing span capacity and material economy. Both truss designs played crucial roles in the expansion of American infrastructure, with the Parker truss often favored for longer spans requiring greater structural efficiency.

Structural Design Differences

Parker truss features a polygonal top chord that reduces material use while efficiently distributing loads, contrasting with the Pratt truss's straight top chord and vertical compression members paired with diagonal tension members. The Parker truss adapts better to longer spans due to its curved top chord, which minimizes bending moments, whereas the Pratt truss excels in shorter spans with simpler geometry. Structural efficiency in the Parker truss arises from variable member lengths and forces, while the Pratt truss relies on a repetitive, predictable pattern that simplifies fabrication and analysis.

Load Distribution and Efficiency

The Parker truss, characterized by a polygonal top chord, enhances load distribution by reducing bending moments in the center span, leading to increased efficiency for longer spans compared to the Pratt truss. The Pratt truss features vertical compression members and diagonal tension members, optimizing efficiency for shorter spans with relatively uniform load distribution. Both designs effectively transfer loads, but the Parker truss achieves superior structural performance in scenarios with variable loads and extended span lengths.

Materials Used in Parker and Pratt Trusses

Parker trusses are typically constructed using high-strength steel or wrought iron due to their curved top chord design, which requires materials capable of withstanding varying tension and compression forces efficiently. Pratt trusses commonly utilize structural steel because their design features vertical members in compression and diagonal members in tension, optimizing the material for these specific load conditions. Both truss types leverage steel's durability and tensile strength, but Parker trusses often demand more precise material quality to accommodate the complex stress distribution along their polygonal top chord.

Advantages of Parker Truss

Parker truss offers improved load distribution due to its polygonal top chord, allowing for longer spans and reduced material usage compared to the Pratt truss. Its design enhances structural efficiency by minimizing bending moments in the top chord, making it ideal for bridges requiring higher strength and durability. The Parker truss provides better resistance to dynamic loads and wind forces, resulting in increased stability and longevity.

Advantages of Pratt Truss

The Pratt truss offers significant advantages including efficient load distribution through diagonal members that handle tension, reducing material use and increasing structural economy. Its simple design facilitates easier fabrication and maintenance compared to the more complex Parker truss, making it ideal for longer spans and heavy loads. Engineers prefer Pratt trusses for bridges and roof structures due to their superior adaptability to varying load conditions and cost-effectiveness in construction.

Typical Applications and Use Cases

Parker trusses are commonly used in long-span bridges and railway structures due to their variable-depth design, which efficiently distributes loads over extended distances. Pratt trusses are favored in shorter to medium-span bridges, industrial buildings, and roof structures because of their straightforward tension and compression member arrangement, facilitating easier construction and maintenance. Both truss types optimize material use, but Parker trusses tend to be selected for heavy-load and long-span applications, while Pratt trusses suit versatile, moderate-span projects.

Cost and Maintenance Considerations

The Parker truss typically involves higher initial costs due to its more complex polygonal top chord design, which requires precise fabrication and longer construction times compared to the simpler Pratt truss. In terms of maintenance, the Parker truss may incur greater expenses because its varied member lengths and angles create more stress points, necessitating frequent inspections and targeted repairs. Conversely, the Pratt truss's straightforward vertical and diagonal member arrangement allows easier access for routine maintenance and generally lower lifecycle costs.

Choosing the Right Truss for Your Project

Choosing between a Parker truss and a Pratt truss depends on project requirements such as span length, load distribution, and aesthetic preferences. Parker trusses, characterized by their polygonal top chords, provide efficient material usage for longer spans and variable loads, making them ideal for bridges and large roofs. Pratt trusses have vertical members in compression and diagonals in tension, offering simplicity and cost-effectiveness for shorter spans and structures requiring straightforward load paths.

Parker truss Infographic

libterm.com

libterm.com