Fracture strength measures the ability of a material to resist breaking under stress, playing a crucial role in engineering and construction applications. Understanding this property helps in designing safer structures and prevents unexpected failures. Explore the detailed analysis of fracture strength and its impact on material performance throughout the rest of the article.

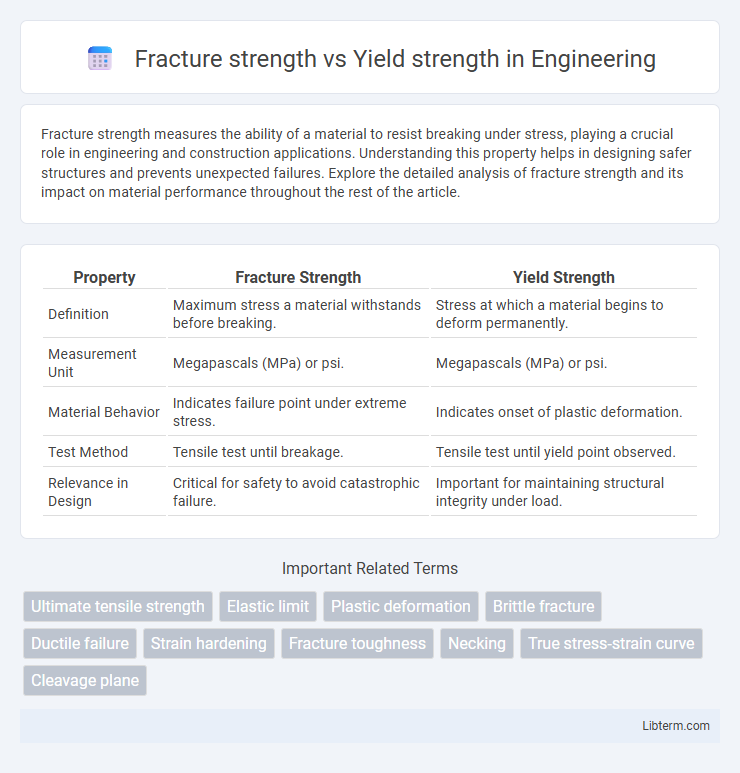

Table of Comparison

| Property | Fracture Strength | Yield Strength |

|---|---|---|

| Definition | Maximum stress a material withstands before breaking. | Stress at which a material begins to deform permanently. |

| Measurement Unit | Megapascals (MPa) or psi. | Megapascals (MPa) or psi. |

| Material Behavior | Indicates failure point under extreme stress. | Indicates onset of plastic deformation. |

| Test Method | Tensile test until breakage. | Tensile test until yield point observed. |

| Relevance in Design | Critical for safety to avoid catastrophic failure. | Important for maintaining structural integrity under load. |

Understanding Fracture Strength and Yield Strength

Fracture strength defines the maximum stress a material can withstand before it breaks, while yield strength indicates the stress level at which a material begins to deform plastically. Understanding the difference between these two mechanical properties is critical for predicting material behavior under different load conditions and ensuring structural integrity. Yield strength is essential for designing components that avoid permanent deformation, whereas fracture strength is crucial for preventing catastrophic failure.

Fundamental Definitions: Fracture Strength vs Yield Strength

Fracture strength is the maximum stress a material can withstand before it breaks or fractures, indicating its ultimate failure point. Yield strength is the stress level at which a material begins to deform plastically, meaning it will not return to its original shape when the stress is removed. Understanding the distinction between fracture strength and yield strength is essential for designing materials and structures that balance durability and flexibility under applied loads.

Key Differences Between Fracture Strength and Yield Strength

Fracture strength refers to the stress level at which a material ultimately breaks or fractures, while yield strength denotes the stress at which a material begins to deform plastically and does not return to its original shape. The key difference lies in their position on the stress-strain curve: yield strength marks the end of elastic behavior, whereas fracture strength represents the maximum stress the material can endure before failure. Understanding these distinct mechanical properties is crucial for selecting materials in engineering applications where both durability and safety are paramount.

Material Behavior Under Stress: Yielding vs Fracture

Yield strength defines the stress level at which a material begins to deform plastically, marking the transition from elastic behavior to permanent deformation. Fracture strength represents the maximum stress a material can withstand before complete failure and separation occurs. Understanding the distinction between yielding and fracture is crucial in material design, as yielding indicates material ductility while fracture strength relates to ultimate structural integrity under stress.

Factors Influencing Yield Strength

Yield strength is primarily influenced by factors such as material composition, grain size, temperature, and strain rate, which affect a material's ability to resist permanent deformation under stress. Alloying elements and heat treatment alter dislocation movement, directly impacting yield strength, whereas fracture strength relates more to a material's resistance to crack propagation and ultimate failure. Understanding these variables helps optimize materials for applications requiring precise mechanical performance and durability.

Factors Affecting Fracture Strength

Fracture strength depends heavily on material properties such as microstructure, presence of flaws, and temperature, which influence how a material resists crack propagation under stress. Factors like grain size, impurity levels, and strain rate critically affect the fracture toughness, directly impacting fracture strength. Yield strength primarily relates to dislocation motion and plastic deformation, but fracture strength is more sensitive to crack initiation and growth dynamics.

Practical Applications: When Yield Strength Matters Most

Yield strength is crucial in practical applications where materials must maintain their shape under operational stress, such as in structural beams, automotive components, and pressure vessels, ensuring safety and performance without permanent deformation. Fracture strength becomes secondary during regular use because it relates to the point of catastrophic failure, which engineers aim to avoid through design limits based on yield strength. In manufacturing and construction, adhering to yield strength constraints prevents costly repairs and catastrophic failures by allowing materials to absorb stress without compromising structural integrity.

Engineering Considerations for Fracture Strength

Fracture strength represents the stress at which a material ultimately fails by cracking, a critical factor in engineering designs subjected to high stress concentrations and dynamic loads. It is essential to consider fracture toughness and flaw sensitivity alongside fracture strength to prevent catastrophic material failure, especially in brittle materials and structural components. Yield strength typically governs elastic and plastic deformation limits, but fracture strength dictates the actual failure point, making it crucial in safety-critical applications such as aerospace, pressure vessels, and structural engineering.

Testing Methods: Measuring Yield and Fracture Strength

Measuring yield strength typically involves tensile testing using a universal testing machine, where the stress at which a material begins to deform plastically is recorded, often identified by the 0.2% offset method. Fracture strength testing requires a more specialized approach, such as using a fracture toughness test setup that includes notched specimens subjected to increasing stress until crack propagation occurs. Both testing methods are crucial in materials engineering, providing essential data for predicting material performance under different loading conditions and ensuring structural integrity.

Choosing the Right Material: Yield Strength vs Fracture Strength

Yield strength defines the stress level at which a material begins to deform plastically, while fracture strength indicates the maximum stress a material can withstand before failure. Selecting materials with a higher yield strength is crucial for applications requiring resistance to permanent deformation, whereas materials with superior fracture strength are essential for ensuring structural integrity under extreme stress. Engineers must evaluate both properties in tandem to optimize safety, durability, and performance in mechanical design.

Fracture strength Infographic

libterm.com

libterm.com