Eddy current testing is a non-destructive technique that uses electromagnetic induction to detect surface and sub-surface flaws in conductive materials. This method is highly effective for identifying cracks, corrosion, and other defects without causing damage. Explore the rest of the article to understand how this advanced testing technique can enhance your inspection processes.

Table of Comparison

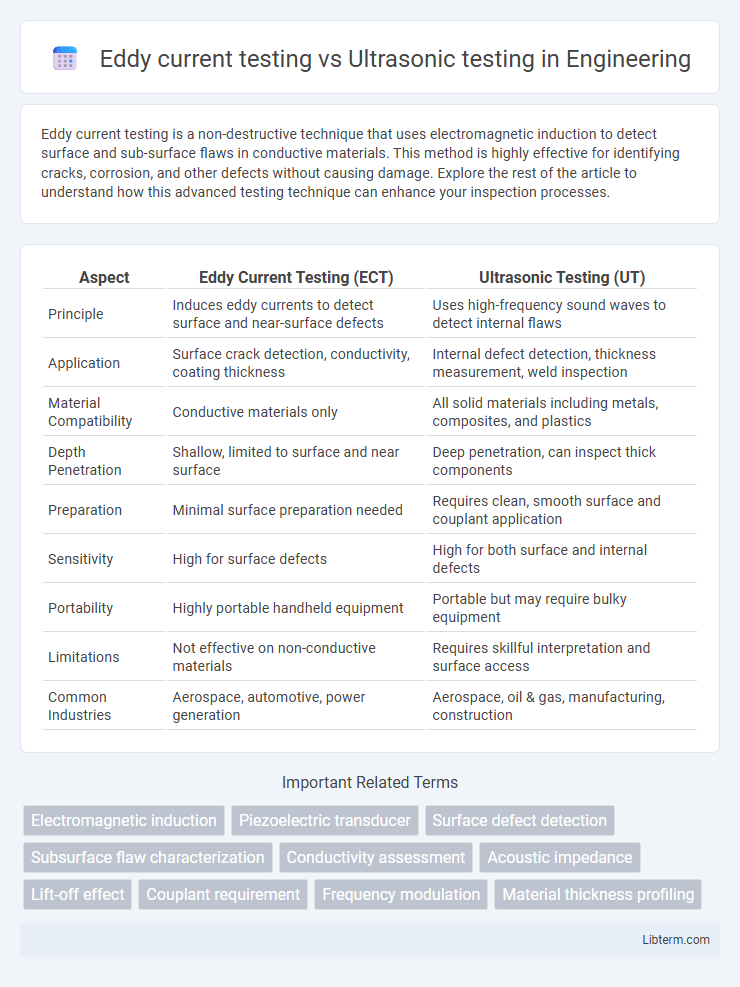

| Aspect | Eddy Current Testing (ECT) | Ultrasonic Testing (UT) |

|---|---|---|

| Principle | Induces eddy currents to detect surface and near-surface defects | Uses high-frequency sound waves to detect internal flaws |

| Application | Surface crack detection, conductivity, coating thickness | Internal defect detection, thickness measurement, weld inspection |

| Material Compatibility | Conductive materials only | All solid materials including metals, composites, and plastics |

| Depth Penetration | Shallow, limited to surface and near surface | Deep penetration, can inspect thick components |

| Preparation | Minimal surface preparation needed | Requires clean, smooth surface and couplant application |

| Sensitivity | High for surface defects | High for both surface and internal defects |

| Portability | Highly portable handheld equipment | Portable but may require bulky equipment |

| Limitations | Not effective on non-conductive materials | Requires skillful interpretation and surface access |

| Common Industries | Aerospace, automotive, power generation | Aerospace, oil & gas, manufacturing, construction |

Introduction to Non-Destructive Testing (NDT) Methods

Eddy current testing utilizes electromagnetic induction to detect surface and near-surface flaws in conductive materials, offering rapid inspection without contact. Ultrasonic testing employs high-frequency sound waves to penetrate materials, identifying internal defects and measuring thickness with high precision. Both methods are critical NDT techniques, providing reliable detection while preserving the integrity of inspected components.

What is Eddy Current Testing?

Eddy Current Testing (ECT) is a non-destructive testing method that uses electromagnetic induction to detect surface and near-surface flaws in conductive materials. It involves inducing eddy currents in the test object with an alternating magnetic field and measuring variations caused by discontinuities or changes in material properties. Primarily used in aerospace, automotive, and manufacturing industries, ECT excels in detecting cracks, corrosion, and conductivity changes without requiring direct contact or couplant.

What is Ultrasonic Testing?

Ultrasonic Testing (UT) is a non-destructive testing method that uses high-frequency sound waves to detect internal flaws or characterize materials. It involves transmitting ultrasonic pulses into a material and analyzing the reflected waves to identify defects such as cracks, voids, or inclusions. Compared to Eddy Current Testing, which primarily assesses surface and near-surface defects in conductive materials, Ultrasonic Testing can detect deeper internal defects across a wide range of material types, including metals, composites, and plastics.

Key Principles: Eddy Current vs Ultrasonic Testing

Eddy current testing utilizes electromagnetic induction to detect surface and near-surface flaws by inducing currents in conductive materials, measuring changes in impedance caused by defects. Ultrasonic testing employs high-frequency sound waves transmitted into materials, analyzing the reflected signals from internal features or discontinuities for flaw detection and thickness measurement. Both methods provide non-destructive evaluation but differ significantly in physical principles, penetration depth, and material compatibility.

Comparison of Applications in Industry

Eddy current testing excels in detecting surface and near-surface defects in conductive materials, making it ideal for inspecting heat exchanger tubes, aircraft fuselages, and weld seams. Ultrasonic testing penetrates deeper into materials, effectively identifying internal flaws in metals, composites, and welds, commonly used in pipeline inspections, aerospace component evaluation, and automotive manufacturing. Industries choose eddy current for rapid, surface-level inspections and ultrasonic testing for comprehensive assessment of structural integrity in critical components.

Sensitivity to Defect Types and Sizes

Eddy current testing excels in detecting surface and near-surface defects, especially in conductive materials, offering high sensitivity to small cracks and corrosion. Ultrasonic testing provides superior detection of subsurface defects, such as internal cracks and inclusions, with the capability to evaluate defect size and depth accurately. The choice between these methods depends on defect location, material properties, and required detection sensitivity.

Material Compatibility and Limitations

Eddy current testing is highly effective for inspecting conductive materials such as aluminum, copper, and stainless steel but cannot be used on non-conductive materials like plastics or ceramics. Ultrasonic testing works well on a wide range of materials including metals, composites, and some plastics, yet requires a smooth, clean surface for effective wave transmission. Eddy current is limited by surface coatings and rough surfaces, while ultrasonic testing faces challenges with coarse-grained materials and complex geometries impacting signal reliability.

Equipment and Setup Differences

Eddy current testing utilizes electromagnetic induction with coils and probes to detect surface and near-surface flaws, requiring conductive materials and minimal surface preparation. Ultrasonic testing employs high-frequency sound waves generated by piezoelectric transducers, capable of inspecting material thickness and internal defects across a wide range of materials. While eddy current equipment is compact and portable with simple setup for immediate scanning, ultrasonic testing demands coupling agents and precise probe positioning to ensure accurate sound transmission and reflection.

Cost, Efficiency, and Training Requirements

Eddy current testing typically offers lower equipment costs and faster inspection speeds compared to ultrasonic testing, making it more cost-efficient for surface crack detection in conductive materials. Ultrasonic testing, while involving higher initial investment and more complex training, provides greater depth penetration and accuracy for detecting internal flaws across various materials. Training requirements for eddy current testing are generally shorter due to simpler signal interpretation, whereas ultrasonic testing demands extensive operator expertise to correctly analyze waveform data and ensure reliable results.

Choosing the Right Method: Factors to Consider

Selecting between Eddy current testing and Ultrasonic testing depends primarily on the material type, defect location, and inspection environment. Eddy current testing excels in detecting surface and near-surface flaws in conductive materials without requiring extensive surface preparation, making it ideal for corrosion and crack detection on metal surfaces. Ultrasonic testing offers deeper penetration for volumetric and internal defect detection in a wide range of materials, including metals, composites, and plastics, and is preferred when precise thickness measurements and subsurface flaw characterization are necessary.

Eddy current testing Infographic

libterm.com

libterm.com