Visual inspection is a crucial process in quality control that involves examining products or components to identify defects, inconsistencies, or damages using the human eye or optical tools. This technique enhances accuracy and efficiency in detecting surface flaws and ensures compliance with industry standards. Discover how visual inspection can improve your operations and quality assurance by reading the rest of this article.

Table of Comparison

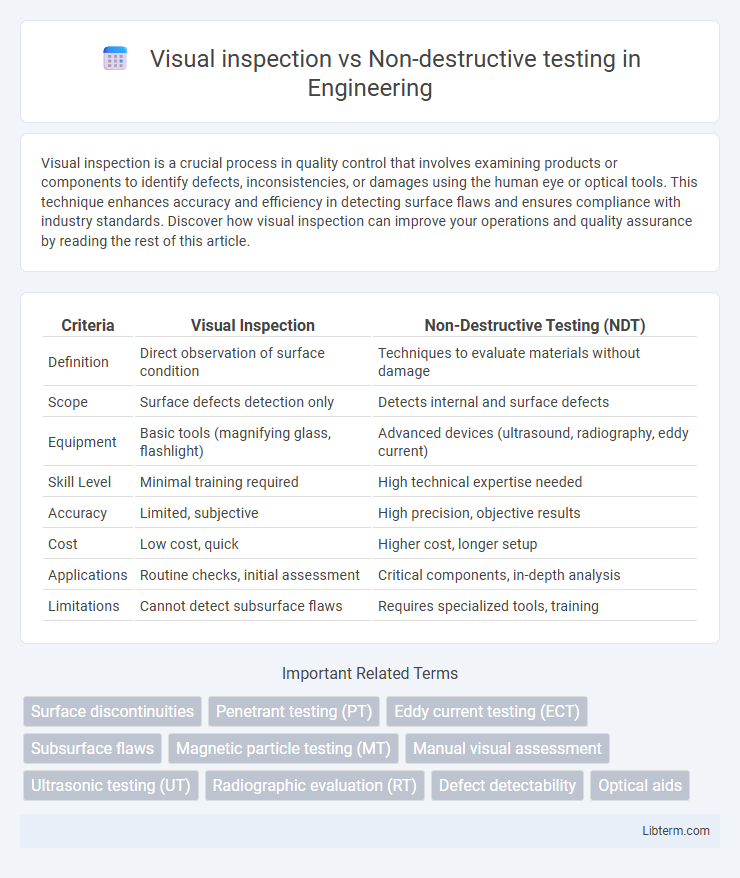

| Criteria | Visual Inspection | Non-Destructive Testing (NDT) |

|---|---|---|

| Definition | Direct observation of surface condition | Techniques to evaluate materials without damage |

| Scope | Surface defects detection only | Detects internal and surface defects |

| Equipment | Basic tools (magnifying glass, flashlight) | Advanced devices (ultrasound, radiography, eddy current) |

| Skill Level | Minimal training required | High technical expertise needed |

| Accuracy | Limited, subjective | High precision, objective results |

| Cost | Low cost, quick | Higher cost, longer setup |

| Applications | Routine checks, initial assessment | Critical components, in-depth analysis |

| Limitations | Cannot detect subsurface flaws | Requires specialized tools, training |

Introduction to Inspection Methods

Visual inspection is the most basic and widely used method for identifying surface defects, cracks, and corrosion by direct observation, requiring minimal equipment and providing immediate results. Non-destructive testing (NDT) encompasses a range of advanced techniques such as ultrasonic testing, radiography, and magnetic particle inspection, enabling detection of internal flaws without damaging the material. These inspection methods are critical in maintaining structural integrity and safety in industries like aerospace, manufacturing, and construction.

Defining Visual Inspection

Visual inspection is a fundamental non-destructive testing (NDT) method involving the direct observation of a material or structure's surface to identify defects, corrosion, or irregularities without causing damage. It relies on the inspector's expertise and can be enhanced by tools such as magnifying glasses, borescopes, or cameras to access hard-to-see areas. Visual inspection serves as the first step in quality control and maintenance, providing immediate, cost-effective detection of surface-level imperfections before more complex NDT techniques are employed.

What is Non-Destructive Testing (NDT)?

Non-Destructive Testing (NDT) is a critical evaluation method used to inspect materials and components without causing any damage or alteration. Techniques such as ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing detect internal and surface defects while preserving the integrity of the item. NDT plays a vital role in quality control, safety assurance, and extending the lifespan of industrial assets across sectors like aerospace, manufacturing, and construction.

Techniques Used in Visual Inspection

Visual inspection techniques include direct observation, magnification tools like microscopes or magnifying glasses, and digital imaging such as high-resolution cameras and video endoscopes. These methods detect surface defects, corrosion, misalignments, and material inconsistencies without harming the inspected object. Visual inspection is often the first step in non-destructive testing (NDT) due to its cost-effectiveness and ease of implementation.

Common Types of Non-Destructive Testing

Common types of Non-Destructive Testing (NDT) include ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing, each offering unique capabilities to detect internal and surface defects without causing damage. Visual inspection serves as a fundamental technique often used in conjunction with these methods to identify visible flaws quickly and guide further NDT processes. Combining visual inspection with advanced NDT methods ensures comprehensive evaluation of material integrity and structural safety.

Strengths of Visual Inspection

Visual inspection excels in cost-effectiveness and rapid assessment, enabling immediate identification of surface defects such as cracks, corrosion, and misalignments without specialized equipment. Its non-intrusive nature allows for frequent monitoring and easy implementation across various industries including manufacturing, aerospace, and construction. Visual inspection's simplicity ensures minimal training requirements, facilitating early detection of potential issues to prevent costly repairs or failures.

Advantages of Non-Destructive Testing

Non-destructive testing (NDT) offers significant advantages over visual inspection by detecting subsurface defects without damaging the material, ensuring structural integrity and safety. Techniques like ultrasonic testing, radiography, and magnetic particle testing provide precise, quantifiable data that improve inspection accuracy and enable early fault detection. NDT also supports continuous monitoring, reducing downtime and maintenance costs while extending the lifespan of critical components in industries such as aerospace, automotive, and manufacturing.

Limitations and Challenges of Each Method

Visual inspection faces limitations such as reliance on operator skill and the inability to detect subsurface defects, making it less effective for complex internal flaws. Non-destructive testing (NDT) methods, while capable of identifying internal anomalies through techniques like ultrasonic or radiographic testing, encounter challenges including higher costs, requirement for specialized equipment, and the need for extensive operator training. Both methods must address issues of accessibility to inspection areas, with visual inspection constrained by line-of-sight and NDT sometimes limited by material properties affecting signal penetration.

Choosing Between Visual Inspection and NDT

Choosing between visual inspection and non-destructive testing (NDT) depends on the complexity of defects, required sensitivity, and budget constraints. Visual inspection offers a quick, cost-effective method for detecting surface anomalies but lacks the depth penetration and accuracy of NDT techniques like ultrasonic, radiographic, or magnetic particle testing. Industries requiring detailed internal flaw detection or compliance with stringent safety standards often prioritize NDT for its reliability in maintaining structural integrity.

Applications and Industry Best Practices

Visual inspection remains the most widespread technique in industries like manufacturing and aerospace for detecting surface defects, corrosion, and assembly errors due to its cost-effectiveness and ease of implementation. Non-destructive testing (NDT) methods such as ultrasonic testing, radiography, and magnetic particle testing provide deeper insight into internal flaws without damaging the asset, widely adopted in oil and gas, automotive, and power generation sectors for safety-critical evaluations. Industry best practices emphasize integrating visual inspection as a preliminary screening tool, supplemented by specific NDT methods tailored to material type, defect characteristics, and regulatory compliance standards to ensure comprehensive quality control and risk mitigation.

Visual inspection Infographic

libterm.com

libterm.com