A composite shaft offers exceptional strength-to-weight ratio improvements compared to traditional metal shafts, making it ideal for applications in automotive, aerospace, and industrial machinery. By using advanced materials like carbon fiber reinforced polymers, composite shafts enhance durability and reduce rotational inertia, contributing to better performance and fuel efficiency. Explore the full article to discover how a composite shaft can revolutionize Your mechanical systems.

Table of Comparison

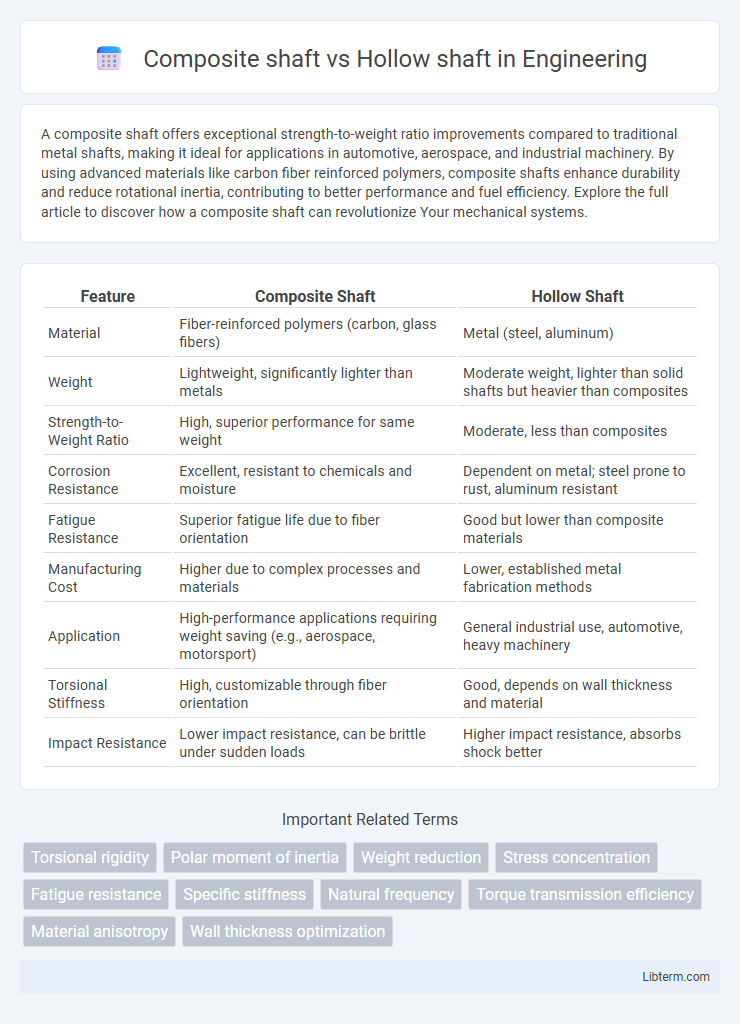

| Feature | Composite Shaft | Hollow Shaft |

|---|---|---|

| Material | Fiber-reinforced polymers (carbon, glass fibers) | Metal (steel, aluminum) |

| Weight | Lightweight, significantly lighter than metals | Moderate weight, lighter than solid shafts but heavier than composites |

| Strength-to-Weight Ratio | High, superior performance for same weight | Moderate, less than composites |

| Corrosion Resistance | Excellent, resistant to chemicals and moisture | Dependent on metal; steel prone to rust, aluminum resistant |

| Fatigue Resistance | Superior fatigue life due to fiber orientation | Good but lower than composite materials |

| Manufacturing Cost | Higher due to complex processes and materials | Lower, established metal fabrication methods |

| Application | High-performance applications requiring weight saving (e.g., aerospace, motorsport) | General industrial use, automotive, heavy machinery |

| Torsional Stiffness | High, customizable through fiber orientation | Good, depends on wall thickness and material |

| Impact Resistance | Lower impact resistance, can be brittle under sudden loads | Higher impact resistance, absorbs shock better |

Introduction to Shaft Types

Composite shafts offer superior strength-to-weight ratios and enhanced torsional stiffness compared to hollow shafts, making them ideal for high-performance automotive and aerospace applications. Hollow shafts reduce weight while maintaining structural integrity, providing cost-effective solutions for various mechanical systems. Both shaft types balance durability and efficiency, with composite materials enabling advanced customization of mechanical properties.

Overview of Composite Shafts

Composite shafts feature lightweight, high-strength materials such as carbon fiber and fiberglass, offering superior stiffness-to-weight ratios compared to traditional metal shafts. These shafts provide enhanced torsional rigidity and vibration damping, improving performance in automotive, aerospace, and industrial applications. Reduced weight contributes to increased fuel efficiency and dynamic response, making composite shafts a preferred choice for high-performance mechanical systems.

Overview of Hollow Shafts

The informal sector often lacks legal protections, social security, and minimum wage guarantees, exposing workers to exploitation and poor working conditions. In contrast, the formal sector provides regulated employment with enforced labor laws, social benefits, and access to healthcare and pensions, promoting worker stability and well-being. The disparity significantly impacts social equity, as informal workers face higher vulnerability without formal rights or institutional support.

Material Properties Comparison

Composite shafts offer superior strength-to-weight ratios compared to hollow shafts, due to materials like carbon fiber reinforced polymers that provide high tensile strength and stiffness with reduced density. Hollow shafts, typically made from metals such as steel or aluminum, exhibit greater ductility and impact resistance but result in higher overall weight. The anisotropic nature of composite materials allows tailored directional stiffness, whereas hollow shafts maintain isotropic mechanical properties.

Strength and Durability Contrast

Composite shafts exhibit superior strength-to-weight ratios compared to hollow shafts, making them ideal for applications requiring high performance and reduced mass. The enhanced durability of composite shafts stems from their resistance to corrosion, fatigue, and impact, whereas hollow shafts, typically made from metals like steel or aluminum, can suffer from corrosion and fatigue over time despite their inherent toughness. Composite shafts maintain structural integrity under cyclic loading better than hollow shafts, contributing to longer service life in demanding environments.

Weight and Performance Analysis

Composite shafts exhibit significantly lower weight compared to hollow shafts due to advanced fiber-reinforced materials, enabling higher strength-to-weight ratios that enhance overall mechanical efficiency. Hollow shafts, while robust and cost-effective, tend to be heavier, which can adversely affect dynamic performance and energy consumption in rotating machinery. Performance analysis reveals that composite shafts offer superior vibration damping and fatigue resistance, making them ideal for aerospace and automotive applications where lightweight and high-strength are critical.

Cost Efficiency Evaluation

Composite shafts demonstrate superior cost efficiency compared to hollow shafts due to reduced material weight and enhanced strength-to-weight ratio, leading to lower manufacturing and transportation costs. Hollow shafts, while offering good strength and durability, typically incur higher expenses in raw material procurement and machining processes. Lifecycle cost analysis reveals composite shafts provide better long-term savings through decreased maintenance and improved fuel efficiency in automotive and aerospace applications.

Applications in Industry

Composite shafts offer superior strength-to-weight ratios and corrosion resistance, making them ideal for aerospace and automotive industries where reducing weight without sacrificing performance is critical. Hollow shafts are widely used in heavy machinery, robotics, and industrial equipment due to their high torsional rigidity and ability to accommodate internal components like wiring or fluids. Both types serve essential roles in power transmission systems, with composite shafts preferred for dynamic applications and hollow shafts favored for robustness under heavy load conditions.

Maintenance and Lifespan

Composite shafts require less maintenance due to their corrosion resistance and reduced susceptibility to fatigue compared to hollow shafts, which often need regular inspections for cracks and corrosion. The lifespan of composite shafts generally exceeds that of hollow shafts, as composites offer higher strength-to-weight ratios and better fatigue endurance. Maintenance costs for composite shafts are typically lower over time, providing enhanced durability in demanding operational environments.

Conclusion: Choosing the Right Shaft

Choosing the right shaft depends on balancing weight, strength, and application demands; composite shafts offer superior strength-to-weight ratios and corrosion resistance, making them ideal for high-performance and lightweight applications. Hollow shafts provide enhanced torsional strength and reduced weight compared to solid shafts, suitable for automotive and industrial machinery requiring durability and flexibility. Selecting between composite and hollow shafts involves evaluating specific load requirements, environmental conditions, and cost considerations to optimize performance and longevity.

Composite shaft Infographic

libterm.com

libterm.com