Age hardening enhances the strength and durability of metals through controlled heat treatment processes that promote precipitation of secondary phases within the alloy. This technique improves mechanical properties such as hardness, tensile strength, and resistance to wear by altering the microstructure. Explore the article to understand how age hardening can benefit your materials and manufacturing applications.

Table of Comparison

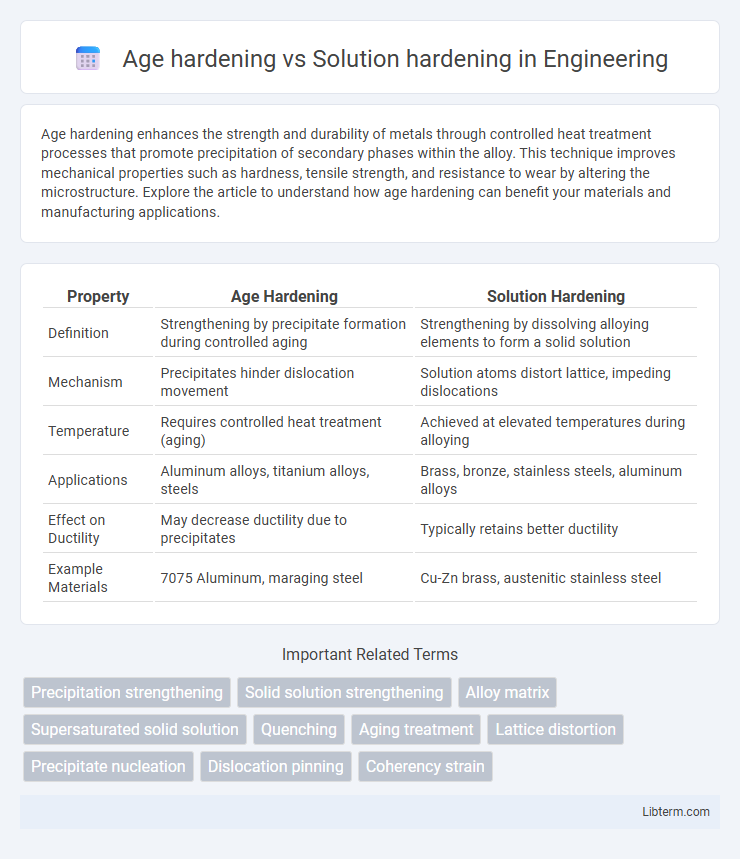

| Property | Age Hardening | Solution Hardening |

|---|---|---|

| Definition | Strengthening by precipitate formation during controlled aging | Strengthening by dissolving alloying elements to form a solid solution |

| Mechanism | Precipitates hinder dislocation movement | Solution atoms distort lattice, impeding dislocations |

| Temperature | Requires controlled heat treatment (aging) | Achieved at elevated temperatures during alloying |

| Applications | Aluminum alloys, titanium alloys, steels | Brass, bronze, stainless steels, aluminum alloys |

| Effect on Ductility | May decrease ductility due to precipitates | Typically retains better ductility |

| Example Materials | 7075 Aluminum, maraging steel | Cu-Zn brass, austenitic stainless steel |

Introduction to Hardening Processes

Age hardening, also known as precipitation hardening, involves the formation of fine particles within the metal matrix to enhance strength and hardness over time at elevated temperatures. Solution hardening achieves increased strength by dissolving alloying elements into the metal's crystal lattice, creating lattice distortions that impede dislocation motion. Both processes are key metallurgical methods to improve mechanical properties by controlling microstructure through heat treatment and alloy composition.

What is Age Hardening?

Age hardening, also known as precipitation hardening, is a heat treatment process that increases the strength and hardness of alloys by forming fine precipitates within the metal matrix. This involves heating the alloy to a high temperature to dissolve solute atoms, followed by rapid cooling and then aging at a lower temperature to allow precipitates to form. Age hardening is commonly used in aluminum, titanium, and nickel-based alloys to enhance mechanical properties without compromising ductility.

What is Solution Hardening?

Solution hardening, also known as solid solution strengthening, occurs when alloying elements dissolve into a metal's crystal lattice, creating lattice distortions that hinder dislocation motion. This process enhances the metal's strength and hardness by increasing the resistance to plastic deformation without changing its microstructure. Common examples include copper alloys with zinc or nickel additions, which improve mechanical properties through atomic-scale interactions within the solution.

Key Differences: Age Hardening vs Solution Hardening

Age hardening, also known as precipitation hardening, involves the formation of fine particles within a metal matrix to increase strength, typically occurring at relatively low temperatures over time. Solution hardening strengthens alloys by dissolving solute atoms uniformly within the solvent metal at high temperatures, creating lattice distortions that impede dislocation movement. The key difference lies in the mechanism: age hardening uses precipitate formation post heat treatment, while solution hardening relies on solute atoms uniformly dispersed in the metal matrix.

Mechanisms Behind Age Hardening

Age hardening involves the formation of finely dispersed precipitates within a metal matrix, which obstruct dislocation movement and increase strength through precipitation strengthening. This process occurs by first creating a supersaturated solid solution via rapid quenching, followed by controlled aging to allow uniform nucleation and growth of coherent precipitates. In contrast, solution hardening relies on the presence of solute atoms that create lattice distortions, impeding dislocation motion without precipitate formation.

Mechanisms Behind Solution Hardening

Solution hardening, also known as solid solution strengthening, occurs when impurity atoms are dissolved in a metal's crystal lattice, creating lattice distortions that impede dislocation movement. These distortions generate internal stresses, raising the critical resolved shear stress required for plastic deformation. In contrast to age hardening, which relies on the formation of fine precipitates during heat treatment, solution hardening depends solely on the atomic size and modulus mismatch introduced by the solute atoms in the solvent matrix.

Materials Suited for Age Hardening

Age hardening is particularly effective for aluminum alloys such as 2024, 6061, and 7075, as well as certain titanium and nickel-based superalloys, where controlled precipitation of secondary phases enhances strength. Solution hardening, conversely, relies on alloying elements dissolved in the matrix to impede dislocation movement, commonly used in austenitic stainless steels and brass. Materials suited for age hardening benefit from heat treatment processes that allow fine precipitates to form, significantly improving yield strength and hardness without compromising ductility.

Materials Suited for Solution Hardening

Solution hardening is most effective in materials with high solid solubility limits, such as aluminum alloys, copper alloys, and certain stainless steels, where substitutional or interstitial solutes create lattice distortions that impede dislocation motion. These materials exhibit enhanced tensile strength and hardness through controlled alloying elements uniformly dissolved in the base metal matrix. In contrast, age hardening relies on precipitation mechanisms and is typically suited for alloys like aluminum 7075 or nickel-based superalloys.

Applications and Industrial Uses

Age hardening enhances the strength and hardness of alloys like aluminum, titanium, and nickel-based superalloys, making them ideal for aerospace, automotive, and military applications requiring high-performance materials. Solution hardening primarily improves the mechanical properties of steels and copper alloys, widely used in construction, shipbuilding, and heavy machinery industries due to enhanced toughness and corrosion resistance. The choice between age hardening and solution hardening depends on the specific material requirements and desired industrial applications, optimizing performance in components subjected to stress and environmental exposure.

Advantages and Limitations of Each Process

Age hardening enhances alloy strength and hardness by precipitating finely dispersed particles within the metal matrix, offering improved mechanical properties and wear resistance; however, it requires precise temperature control and aging time to prevent over-aging or reduced ductility. Solution hardening increases strength by introducing solute atoms into the metal matrix, creating lattice distortions that hinder dislocation movement, with the advantage of simplicity and uniform strengthening but often limited by reduced corrosion resistance and lower maximum attainable hardness compared to precipitation hardening. Both processes are critical in tailoring material properties for specific applications yet must be selected based on desired balance between strength, ductility, and environmental resistance.

Age hardening Infographic

libterm.com

libterm.com