A U-tube gauge is an essential device used to measure pressure by comparing the height difference of liquid in a U-shaped tube. It operates based on the principle of hydrostatic equilibrium, where the pressure applied causes the liquid levels to change, providing a visual indication of pressure magnitude. Explore the full article to understand how a U-tube gauge can enhance your pressure measurement accuracy.

Table of Comparison

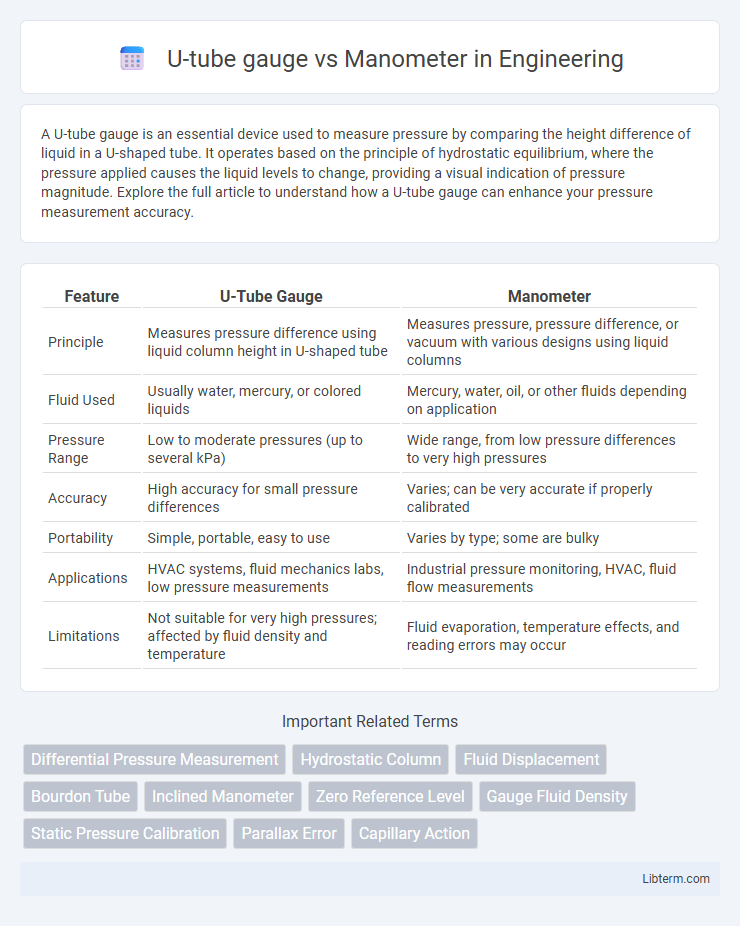

| Feature | U-Tube Gauge | Manometer |

|---|---|---|

| Principle | Measures pressure difference using liquid column height in U-shaped tube | Measures pressure, pressure difference, or vacuum with various designs using liquid columns |

| Fluid Used | Usually water, mercury, or colored liquids | Mercury, water, oil, or other fluids depending on application |

| Pressure Range | Low to moderate pressures (up to several kPa) | Wide range, from low pressure differences to very high pressures |

| Accuracy | High accuracy for small pressure differences | Varies; can be very accurate if properly calibrated |

| Portability | Simple, portable, easy to use | Varies by type; some are bulky |

| Applications | HVAC systems, fluid mechanics labs, low pressure measurements | Industrial pressure monitoring, HVAC, fluid flow measurements |

| Limitations | Not suitable for very high pressures; affected by fluid density and temperature | Fluid evaporation, temperature effects, and reading errors may occur |

Introduction to U-tube Gauges and Manometers

U-tube gauges and manometers are essential instruments for measuring fluid pressure by comparing it against atmospheric or reference pressure. A U-tube gauge consists of a transparent tube shaped like a 'U' filled with a liquid, typically mercury or water, where pressure differences cause liquid displacement that indicates the pressure value. Manometers function on the same principle but can vary in design, including digital and inclined manometers, offering precise measurements in various industrial and laboratory applications.

Basic Working Principles of U-tube Gauges

U-tube gauges operate based on the principle of balancing pressure differences using a liquid column, typically mercury or water, in a U-shaped tube. The pressure applied on one side causes the liquid to rise or fall, creating a measurable height difference proportional to the pressure difference. This height variation directly correlates to pressure values, allowing accurate measurement of pressure in various applications.

How Manometers Measure Pressure

Manometers measure pressure by comparing the height difference of a liquid column, typically mercury or water, in a U-shaped tube to determine the pressure exerted by a gas or fluid. The liquid column moves in response to pressure changes, with the difference in height directly proportional to the pressure value based on hydrostatic principles. Unlike U-tube gauges, which often measure differential pressure in closed systems, manometers provide precise readings of absolute or gauge pressure using simple, gravity-based mechanics.

Key Differences Between U-tube Gauges and Manometers

U-tube gauges primarily measure pressure differences by balancing a fluid column against the pressure, using a simple U-shaped tube filled with liquid like mercury or water, whereas manometers encompass a broader category of devices designed to measure pressure, including both U-tube and digital variations. The key difference lies in U-tube gauges being typically more manual and limited to static pressure comparisons, while manometers can offer enhanced accuracy, digital readouts, and applications across varying pressure types such as gauge, differential, or vacuum measurements. Material selection in U-tube gauges affects responsiveness and range, whereas manometers often incorporate sensors or electronic components for improved precision and ease of use in industrial and laboratory environments.

Types of Manometers Explained

U-tube gauges are a type of manometer that use a U-shaped tube filled with liquid, usually mercury or water, to measure pressure differences by the height difference of the liquid columns. Manometers vary in type, including simple U-tube manometers, inclined manometers for higher sensitivity, and digital manometers for electronic pressure readings. Each type of manometer offers distinct advantages in accuracy, range, and application suitability for measuring gas or liquid pressures in laboratories and industrial settings.

Advantages of U-tube Gauges

U-tube gauges offer high accuracy and stability in measuring pressure due to their simple design and reliable liquid column principle. They require no external power source, making them cost-effective and easy to maintain in various industrial applications. The visual clarity of fluid displacement in U-tube gauges allows for straightforward, precise readings compared to manometers, which may be affected by temperature and fluid density variations.

Benefits of Using Manometers

Manometers provide precise and reliable pressure measurements due to their simple construction and direct reading capability, making them ideal for low-pressure applications. Their ease of maintenance and calibration ensures long-term accuracy, unlike U-tube gauges that can be affected by fluid density variations. Manometers also offer greater sensitivity and can measure extremely small pressure differences, enhancing their effectiveness in laboratory and industrial processes.

Common Applications in Industry

U-tube gauges and manometers are widely used for measuring pressure differences in industrial settings, such as HVAC systems, fluid flow monitoring, and laboratory experiments. U-tube gauges are preferred in applications requiring simple, low-cost, and highly accurate differential pressure readings, often found in water treatment plants and air filtration systems. Manometers, especially digital or inclined types, are favored in chemical processing and pharmaceutical industries for precise pressure measurement and calibration of gas flow instruments.

Factors to Consider When Choosing Between U-tube and Manometer

Choosing between a U-tube gauge and a manometer depends on accuracy requirements, pressure range, and fluid compatibility with the measuring device. U-tube gauges offer simplicity and reliability for low-pressure measurements using a liquid column, while manometers provide greater versatility with different designs suitable for various pressure types and environments. Consider factors such as measurement precision, ease of reading, maintenance needs, and the working fluid's density when selecting the appropriate instrument.

Summary and Final Recommendations

U-tube gauges offer high precision measurement of pressure differences using a liquid column, making them suitable for low-pressure applications and laboratory environments. Manometers vary in design, including digital and inclined types, providing flexibility for both industrial and educational use with a broader pressure range. For accuracy in static pressure measurements, U-tube gauges are recommended, while manometers are preferable for versatile and dynamic pressure monitoring needs.

U-tube gauge Infographic

libterm.com

libterm.com