Selective Laser Sintering (SLS) is an advanced additive manufacturing technique that uses a high-powered laser to fuse powdered materials layer by layer into solid, functional parts. This process enables the creation of complex geometries with high precision and durability, making it ideal for prototyping and low-volume production across various industries. Explore the rest of the article to discover how SLS can elevate your manufacturing capabilities and design innovation.

Table of Comparison

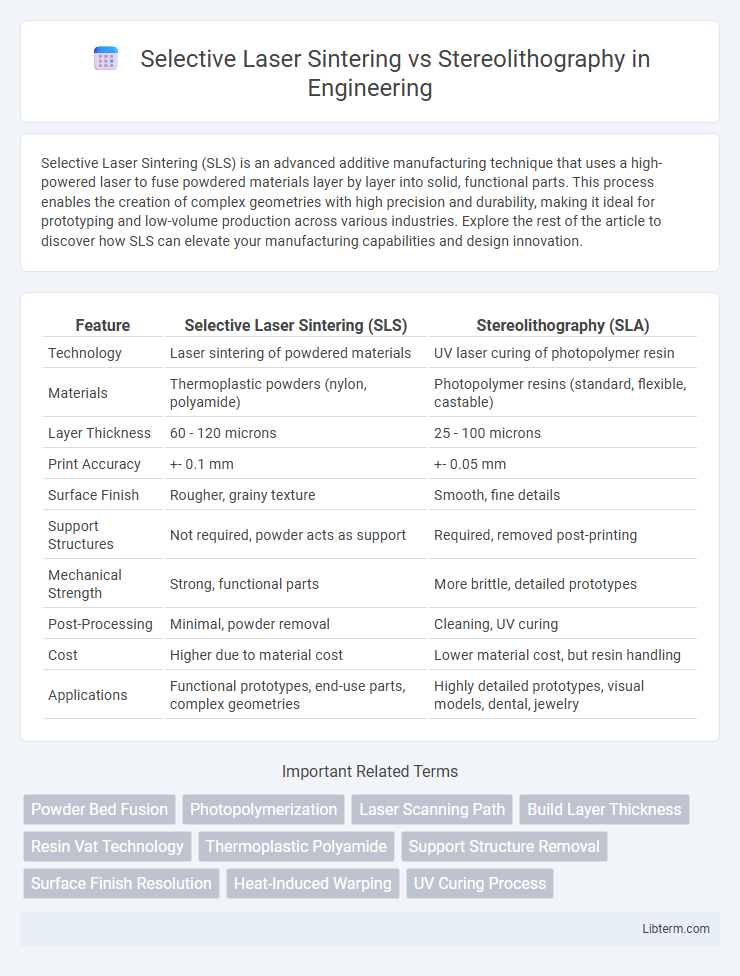

| Feature | Selective Laser Sintering (SLS) | Stereolithography (SLA) |

|---|---|---|

| Technology | Laser sintering of powdered materials | UV laser curing of photopolymer resin |

| Materials | Thermoplastic powders (nylon, polyamide) | Photopolymer resins (standard, flexible, castable) |

| Layer Thickness | 60 - 120 microns | 25 - 100 microns |

| Print Accuracy | +- 0.1 mm | +- 0.05 mm |

| Surface Finish | Rougher, grainy texture | Smooth, fine details |

| Support Structures | Not required, powder acts as support | Required, removed post-printing |

| Mechanical Strength | Strong, functional parts | More brittle, detailed prototypes |

| Post-Processing | Minimal, powder removal | Cleaning, UV curing |

| Cost | Higher due to material cost | Lower material cost, but resin handling |

| Applications | Functional prototypes, end-use parts, complex geometries | Highly detailed prototypes, visual models, dental, jewelry |

Introduction to 3D Printing Technologies

Selective Laser Sintering (SLS) and Stereolithography (SLA) represent two core 3D printing technologies with distinct processes and material compatibilities. SLS uses a laser to sinter powdered materials like nylon or metals, creating durable and complex geometries without support structures, ideal for functional prototypes and end-use parts. SLA utilizes a UV laser to cure liquid resin layer-by-layer, producing high-resolution, smooth-surfaced models commonly used for detailed prototypes and dental or jewelry applications.

Overview of Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is an additive manufacturing process that uses a high-power laser to fuse powdered materials layer by layer, enabling the creation of complex geometries without support structures. SLS materials commonly include nylon, polyamides, and composite powders, offering excellent mechanical properties and thermal resistance. This technology is widely utilized in industries such as aerospace, automotive, and healthcare for rapid prototyping and functional end-use parts production.

Understanding Stereolithography (SLA)

Stereolithography (SLA) is an additive manufacturing process that uses a UV laser to cure liquid photopolymer resin layer by layer, resulting in highly detailed and smooth surface finishes. SLA excels in producing complex geometries with tight tolerances, making it ideal for prototypes, dental molds, and jewelry. Compared to Selective Laser Sintering (SLS), which fuses powdered materials, SLA offers superior resolution but typically uses limited material options like photopolymers.

Key Differences: SLS vs SLA Processes

Selective Laser Sintering (SLS) uses a laser to fuse powdered materials, allowing the creation of complex geometries without support structures, while Stereolithography (SLA) employs a UV laser to cure liquid resin layer by layer, resulting in smoother surface finishes and finer details. SLS materials typically include nylon, polyamides, and composites, offering strong, durable parts suitable for functional prototypes, whereas SLA materials comprise photopolymer resins optimized for high resolution and aesthetic models. The SLS process enables faster production and better mechanical properties for end-use applications, contrasting with SLA's precision and ideal use in detailed prototypes and casting patterns.

Material Options in SLS and SLA

Selective Laser Sintering (SLS) offers a wide range of material options including nylon, polyamide, glass-filled composites, and flexible elastomers, enabling robust and functional prototypes and end-use parts. Stereolithography (SLA) primarily uses photopolymer resins, with specialized options such as standard, tough, flexible, and castable resins tailored for high-detail, smooth surface finishes. Material versatility in SLS supports durable and heat-resistant applications, while SLA materials excel in precision and fine detail for aesthetic or intricate designs.

Print Quality and Surface Finish Comparison

Selective Laser Sintering (SLS) offers robust mechanical properties with a slightly grainy surface finish due to its powder-based process, making it ideal for functional prototypes and end-use parts. Stereolithography (SLA) excels in delivering high-resolution prints with smooth, detailed surfaces, suitable for intricate models and visual prototypes requiring fine detail. Print quality in SLA is generally superior with sharper edges and finer details, while SLS provides durability and versatility at the expense of a rougher texture.

Strength and Durability of Printed Parts

Selective Laser Sintering (SLS) produces parts with superior strength and durability due to its ability to fuse powdered materials into fully dense, functional components, ideal for mechanical applications and functional prototypes. Stereolithography (SLA), while offering excellent surface finish and fine detail, generally results in brittle parts that are less durable under mechanical stress compared to SLS prints. SLS parts typically exhibit higher impact resistance and thermal stability, making them preferable for end-use products requiring robust performance.

Cost Considerations: SLS vs SLA

Selective Laser Sintering (SLS) generally incurs higher initial equipment costs compared to Stereolithography (SLA), but offers cost advantages for larger production runs due to its ability to sinter powder without the need for support structures. SLA typically has lower upfront costs and produces smoother surface finishes, yet its resin materials tend to be more expensive and less durable, affecting long-term cost efficiency. Both technologies present distinct cost dynamics, with SLS better suited for functional prototypes and end-use parts while SLA excels in detailed, high-precision models.

Ideal Applications for SLS and SLA

Selective Laser Sintering (SLS) excels in producing durable, functional prototypes and complex geometries from a wide range of thermoplastic materials, making it ideal for automotive, aerospace, and industrial parts requiring high strength and heat resistance. Stereolithography (SLA) specializes in delivering high-resolution, smooth surface finishes suitable for detailed models, dental molds, jewelry prototypes, and highly accurate visual or presentation pieces. The decision between SLS and SLA hinges on the required mechanical properties and surface quality, with SLS favored for robust parts and SLA preferred for meticulous detail and fine accuracy.

Choosing the Right Technology for Your Project

Selective Laser Sintering (SLS) excels in producing durable, functional prototypes and complex geometries using powdered materials like nylon, making it ideal for engineering applications requiring strength and flexibility. Stereolithography (SLA) offers superior surface finish and high precision with photopolymer resins, perfect for detailed models and visual prototypes where accuracy and smoothness are critical. Choosing the right technology depends on project requirements such as material properties, dimensional accuracy, mechanical strength, and budget constraints.

Selective Laser Sintering Infographic

libterm.com

libterm.com