A potentiometer is a versatile electronic component that adjusts voltage levels by varying resistance within circuits, making it essential for controlling devices like volume knobs and light dimmers. Its simple design combines a resistive element with a movable wiper, allowing precise manual adjustments to your electronic projects. Discover how potentiometers can optimize your designs by exploring the detailed insights in the rest of this article.

Table of Comparison

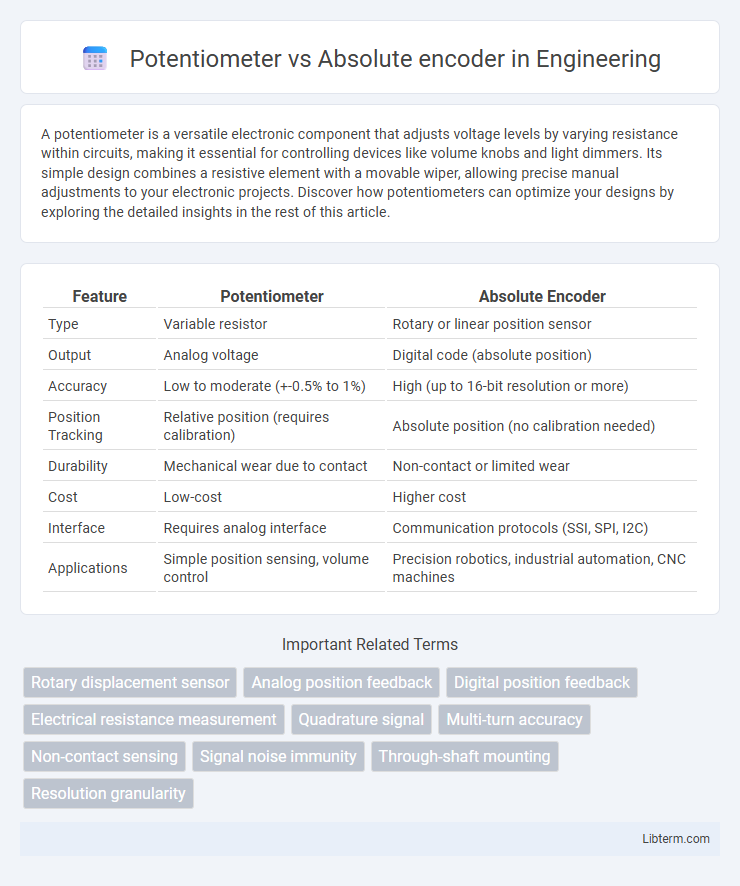

| Feature | Potentiometer | Absolute Encoder |

|---|---|---|

| Type | Variable resistor | Rotary or linear position sensor |

| Output | Analog voltage | Digital code (absolute position) |

| Accuracy | Low to moderate (+-0.5% to 1%) | High (up to 16-bit resolution or more) |

| Position Tracking | Relative position (requires calibration) | Absolute position (no calibration needed) |

| Durability | Mechanical wear due to contact | Non-contact or limited wear |

| Cost | Low-cost | Higher cost |

| Interface | Requires analog interface | Communication protocols (SSI, SPI, I2C) |

| Applications | Simple position sensing, volume control | Precision robotics, industrial automation, CNC machines |

Introduction to Potentiometers and Absolute Encoders

Potentiometers are variable resistors that measure angular or linear position by varying resistance, offering simple, cost-effective position feedback in control systems. Absolute encoders provide precise position information by generating unique digital codes for each mechanical position, ensuring accurate and repeatable readings even after power loss. Both devices serve critical roles in motion control, with potentiometers favored for simplicity and cost, and absolute encoders preferred for high precision and reliability.

How Potentiometers Work

Potentiometers operate by varying resistance through the mechanical movement of a wiper across a resistive element, translating angular or linear displacement into a corresponding voltage output. This analog sensor provides a continuous position signal by dividing the input voltage proportionally according to the wiper position. Unlike absolute encoders, which provide discrete digital position data, potentiometers deliver smooth, variable electrical signals ideal for measuring variable angles or linear positions in control applications.

How Absolute Encoders Function

Absolute encoders function by using a unique code or position value for every shaft angle, providing precise and unambiguous angular position without needing a reference point or reset after power loss. They employ optical, magnetic, or capacitive sensors to read a patterned disk or scale, translating physical position into a digital output signal. This mechanism enables absolute encoders to offer reliable position feedback in applications requiring precise motion control and repeatability.

Key Differences Between Potentiometers and Absolute Encoders

Potentiometers measure angular position through a variable resistance, providing analog signals, while absolute encoders deliver digital outputs representing unique position values for each angle. Potentiometers are susceptible to wear and signal noise due to mechanical contact, whereas absolute encoders offer higher accuracy, reliability, and noise immunity with contactless sensing technology. The resolution of absolute encoders typically surpasses that of potentiometers, making encoders preferable for applications requiring precise position feedback and repeatability.

Accuracy and Resolution Comparison

Potentiometers typically offer lower accuracy and resolution compared to absolute encoders, with accuracy often around +-0.5% to +-1% full scale and resolution limited by mechanical and electrical noise. Absolute encoders provide high precision measurements with accuracy ranging from +-0.01deg to +-0.1deg and resolutions exceeding 12 bits, enabling detailed angular positioning. The superior resolution and repeatability of absolute encoders make them ideal for applications demanding precise control and reliable feedback.

Durability and Lifespan Considerations

Potentiometers typically have shorter lifespans due to mechanical wear on their resistive tracks, often lasting around 1 to 10 million rotations depending on the quality and application conditions. Absolute encoders feature non-contact sensing technologies, such as optical or magnetic methods, which significantly enhance durability and can exceed 100 million cycles without performance degradation. For industrial environments requiring long-term reliability under harsh conditions, absolute encoders provide superior lifespan and reduced maintenance compared to traditional potentiometers.

Cost and Budget Implications

Potentiometers generally offer a lower upfront cost compared to absolute encoders, making them attractive for budget-conscious projects requiring basic position feedback. Absolute encoders, while more expensive initially, provide long-term savings by delivering higher accuracy and reliability, reducing maintenance costs and downtime in complex applications. Budget decisions should weigh initial expenses against the potential for improved system performance and durability inherent in absolute encoder technology.

Applications in Industry and Robotics

Potentiometers are widely used in industrial applications for precise position sensing in motor controls, robotic arms, and conveyor systems due to their simplicity and cost-effectiveness. Absolute encoders provide critical feedback in robotics and automation where exact position data is essential for motion control, safety systems, and multi-axis coordination, offering non-volatile position data even after power loss. Industries such as automotive manufacturing, aerospace, and assembly lines rely on absolute encoders for their reliability and accuracy in complex, high-precision tasks.

Pros and Cons of Potentiometers

Potentiometers offer simplicity, cost-effectiveness, and ease of integration in position sensing applications but suffer from limited lifespan due to wear and susceptibility to noise and environmental factors. Their analog output provides smooth signal variation but lacks the precision and absolute position feedback found in absolute encoders. While potentiometers are ideal for low-cost, low-accuracy needs, absolute encoders excel in applications requiring high resolution, durability, and immunity to signal loss.

Pros and Cons of Absolute Encoders

Absolute encoders provide precise position feedback with unique digital codes for each shaft angle, ensuring accurate and reliable measurement even after power loss. They offer high resolution, robustness against electrical noise, and do not require re-homing or calibration after startup. However, absolute encoders tend to be more expensive, complex to integrate, and may have slower update rates compared to potentiometers, which are simpler and cost-effective for basic applications.

Potentiometer Infographic

libterm.com

libterm.com