A fracture occurs when a bone breaks or cracks due to trauma, overuse, or underlying medical conditions affecting bone strength. Proper diagnosis and treatment are essential for optimal healing and to prevent complications such as improper bone alignment or chronic pain. Explore the rest of the article to learn more about fracture symptoms, types, and effective recovery methods for your well-being.

Table of Comparison

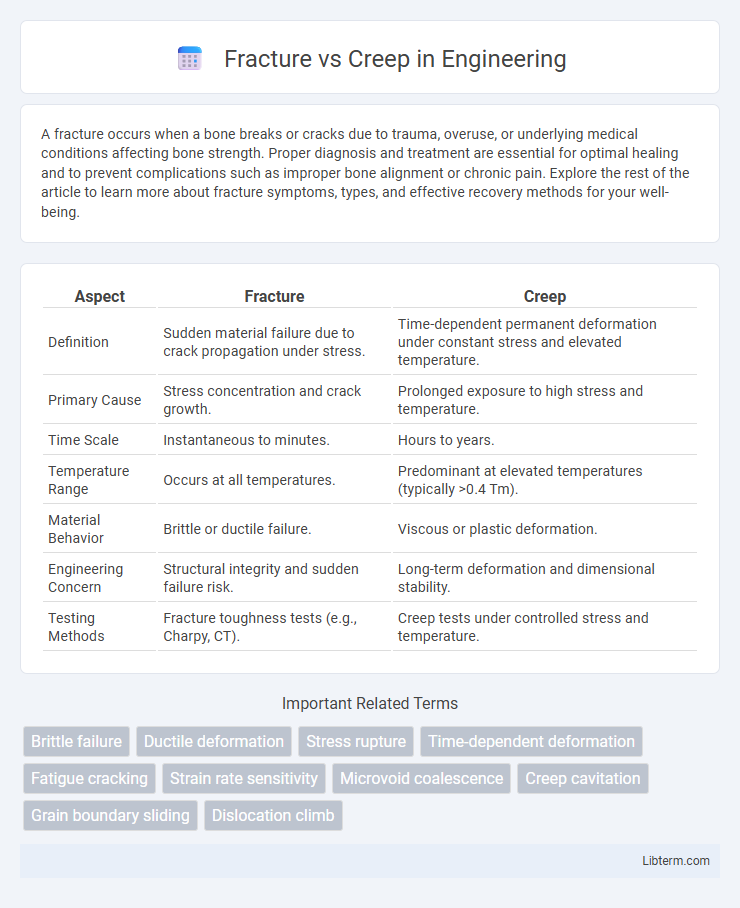

| Aspect | Fracture | Creep |

|---|---|---|

| Definition | Sudden material failure due to crack propagation under stress. | Time-dependent permanent deformation under constant stress and elevated temperature. |

| Primary Cause | Stress concentration and crack growth. | Prolonged exposure to high stress and temperature. |

| Time Scale | Instantaneous to minutes. | Hours to years. |

| Temperature Range | Occurs at all temperatures. | Predominant at elevated temperatures (typically >0.4 Tm). |

| Material Behavior | Brittle or ductile failure. | Viscous or plastic deformation. |

| Engineering Concern | Structural integrity and sudden failure risk. | Long-term deformation and dimensional stability. |

| Testing Methods | Fracture toughness tests (e.g., Charpy, CT). | Creep tests under controlled stress and temperature. |

Introduction to Fracture and Creep

Fracture and creep represent two critical deformation and failure mechanisms in materials under stress. Fracture refers to the separation or breaking of a material into pieces due to applied forces exceeding its strength, often characterized by crack initiation and propagation. Creep describes the time-dependent, gradual deformation of materials under constant stress, typically occurring at high temperatures, leading to eventual failure without immediate fracture.

Fundamental Definitions: Fracture vs Creep

Fracture refers to the sudden failure of a material when it experiences stress beyond its strength, resulting in the formation of cracks and complete separation. Creep is the slow, time-dependent deformation of a material under constant stress, typically occurring at high temperatures. Understanding the fundamental difference highlights that fracture is instantaneous and catastrophic, whereas creep is a gradual process leading to material deformation over extended periods.

Mechanisms of Fracture in Materials

Fracture in materials occurs when stress exceeds the material's intrinsic strength, leading to crack initiation and propagation through mechanisms like brittle fracture, characterized by rapid crack growth without significant plastic deformation, or ductile fracture, involving significant plastic deformation and void coalescence. Creep, on the other hand, involves time-dependent deformation under constant stress at elevated temperatures, primarily driven by mechanisms such as dislocation creep and grain boundary sliding, which weaken the material's resistance to fracture over prolonged periods. Understanding the interplay between fracture mechanisms and creep deformation is critical for predicting lifetime and failure in high-temperature applications like turbine blades and pressure vessels.

Creep Behavior: Causes and Characteristics

Creep behavior occurs when materials experience slow, time-dependent deformation under constant stress at high temperatures, often near their melting point. The primary causes include prolonged exposure to stress, elevated temperature, and microstructural changes such as grain boundary sliding and dislocation movement. Characteristic stages of creep include primary (decreasing rate), secondary (steady rate), and tertiary (accelerating rate leading to failure), critical for predicting material lifespan in applications like turbine blades and pressure vessels.

Key Differences Between Fracture and Creep

Fracture is a sudden failure of a material due to stress exceeding its ultimate strength, whereas creep is the slow, time-dependent deformation of a material under constant stress at elevated temperatures. Fracture results in immediate breakage or cracking, while creep manifests as gradual elongation or shape change without immediate rupture. The key difference lies in timescale and conditions: fracture occurs rapidly under high stress, and creep occurs over prolonged periods under moderate stress and high temperature.

Factors Influencing Fracture and Creep

Fracture and creep are influenced by distinct factors related to material properties and environmental conditions. Fracture is primarily governed by stress concentration, temperature, material toughness, and microstructural defects such as cracks or voids, which initiate brittle or ductile failure. Creep behavior depends on prolonged exposure to high temperature, applied stress, grain boundary diffusion, and material creep resistance, leading to time-dependent plastic deformation under constant load.

Material Selection: Minimizing Fracture and Creep

Material selection to minimize fracture and creep involves choosing alloys with high fracture toughness and creep resistance, such as nickel-based superalloys for high-temperature applications. Grain size refinement and phase stability are critical factors, as fine grains improve fracture resistance while stable phases reduce creep deformation under stress. Incorporating elements like chromium and molybdenum enhances oxidation resistance and mechanical strength, optimizing material performance in demanding environments.

Testing Methods for Fracture and Creep Resistance

Fracture testing methods commonly include Charpy impact tests and fracture toughness tests like ASTM E399, designed to evaluate material behavior under sudden loads and crack propagation resistance. Creep resistance assessment relies on long-term creep tests conducted at elevated temperatures, measuring deformation over time according to standards such as ASTM E139. Both testing methods provide critical data for predicting material performance in high-stress or high-temperature environments, ensuring reliability and safety in engineering applications.

Real-World Applications and Case Studies

Fracture and creep are critical factors in material performance across industries such as aerospace, civil engineering, and nuclear power, where structural integrity under stress and prolonged exposure to high temperatures is paramount. Real-world case studies reveal that fracture often leads to sudden failure in components like aircraft fuselages and bridges, while creep results in gradual deformation in turbine blades and pipelines, necessitating distinct monitoring and maintenance strategies. Advanced materials and simulation techniques are employed to predict fracture toughness and creep rates, enhancing safety and extending the lifespan of critical infrastructure.

Conclusion: Importance in Material Design and Engineering

Fracture and creep are critical failure mechanisms that significantly influence material design and engineering decisions, especially in high-stress and high-temperature environments. Understanding fracture toughness and creep resistance enables engineers to select and develop materials that ensure structural integrity and longevity under specific operating conditions. Optimizing these properties reduces the risk of catastrophic failure, enhances safety, and improves overall performance in applications ranging from aerospace to power generation.

Fracture Infographic

libterm.com

libterm.com