Resonant frequency is the specific frequency at which a system naturally oscillates with maximum amplitude due to minimal energy loss. Understanding this concept is crucial for optimizing the performance of mechanical, electrical, and acoustic systems by preventing unwanted vibrations or enhancing signal clarity. Explore the rest of the article to learn how to identify and apply resonant frequency in practical scenarios.

Table of Comparison

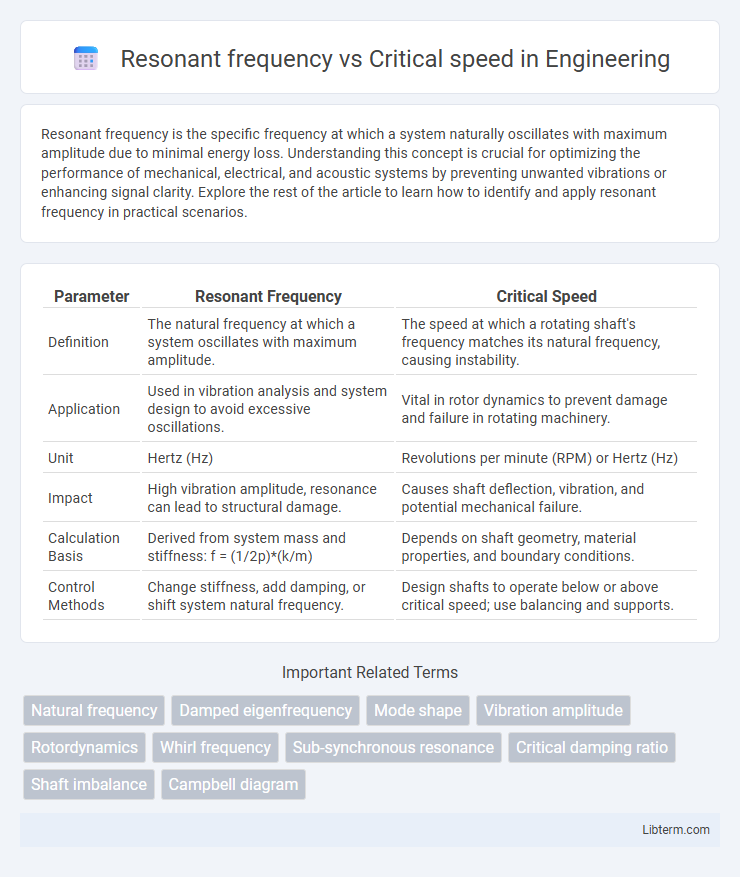

| Parameter | Resonant Frequency | Critical Speed |

|---|---|---|

| Definition | The natural frequency at which a system oscillates with maximum amplitude. | The speed at which a rotating shaft's frequency matches its natural frequency, causing instability. |

| Application | Used in vibration analysis and system design to avoid excessive oscillations. | Vital in rotor dynamics to prevent damage and failure in rotating machinery. |

| Unit | Hertz (Hz) | Revolutions per minute (RPM) or Hertz (Hz) |

| Impact | High vibration amplitude, resonance can lead to structural damage. | Causes shaft deflection, vibration, and potential mechanical failure. |

| Calculation Basis | Derived from system mass and stiffness: f = (1/2p)*(k/m) | Depends on shaft geometry, material properties, and boundary conditions. |

| Control Methods | Change stiffness, add damping, or shift system natural frequency. | Design shafts to operate below or above critical speed; use balancing and supports. |

Introduction to Resonant Frequency and Critical Speed

Resonant frequency is the specific frequency at which a system naturally oscillates with maximum amplitude due to minimal energy dissipation, crucial in mechanical and structural engineering for predicting vibrational behavior. Critical speed refers to the rotational speed at which the system's natural frequency aligns with the excitation frequency, causing excessive vibrations and potential mechanical failure. Understanding the relationship between resonant frequency and critical speed is essential for designing safe and efficient rotating machinery like turbines, motors, and shafts.

Fundamental Concepts: Vibration and Rotational Dynamics

Resonant frequency refers to the natural vibration rate at which a system oscillates with maximum amplitude due to external forces matching this frequency, fundamental in vibration analysis of mechanical systems. Critical speed is the rotational velocity at which a rotating shaft or rotor experiences resonance, causing excessive vibrations that can lead to failure. Understanding the interplay between resonant frequency and critical speed is essential in designing rotating machinery to ensure operational stability and avoid destructive resonance conditions.

Resonant Frequency: Definition and Significance

Resonant frequency is the specific frequency at which a system naturally oscillates with maximum amplitude due to the buildup of energy from external periodic forces matching the system's natural vibration rate. This phenomenon is significant in mechanical and structural engineering, as operating at or near resonant frequency can cause excessive vibrations, leading to fatigue or catastrophic failure. Understanding resonant frequency allows engineers to design components and structures that avoid resonance conditions, ensuring stability and longevity in machinery and construction.

Critical Speed: Definition and Importance

Critical speed refers to the rotational speed at which a rotating shaft or machine component experiences resonance, leading to excessive vibration and potential mechanical failure. Understanding critical speed is essential for designing machinery like turbines, rotors, and driveshafts to avoid destructive resonance conditions that compromise performance and safety. Proper calculation and mitigation of critical speed ensure operational stability, extend equipment life, and prevent costly downtime.

Key Differences Between Resonant Frequency and Critical Speed

Resonant frequency refers to the natural frequency at which a system oscillates with maximum amplitude due to resonance, whereas critical speed specifically denotes the rotational speed at which a rotating shaft experiences excessive vibration leading to potential failure. Resonant frequency is a property inherent to both static and dynamic systems, while critical speed applies primarily to rotating machinery and depends on factors such as shaft stiffness, mass distribution, and support conditions. Understanding these distinctions is essential for engineers to design vibration-free mechanical systems and prevent structural damage or machinery breakdown.

Factors Affecting Resonant Frequency and Critical Speed

Resonant frequency is primarily influenced by the stiffness and mass distribution of a system, with material properties and boundary conditions playing crucial roles in determining the vibration response. Critical speed depends on factors such as shaft geometry, rotational speed, and the dynamic stiffness of bearings and supports, impacting the onset of instability in rotating machinery. Both parameters are affected by changes in temperature, load conditions, and structural damping, which alter the system's natural frequencies and stability thresholds.

Methods for Calculating Resonant Frequency and Critical Speed

Resonant frequency calculation methods often involve analytical techniques such as the Rayleigh method, Dunkerley's approximation, and finite element analysis (FEA) to evaluate the natural frequencies of vibrating systems. Critical speed determination primarily relies on rotor dynamics models, including the Jeffcott rotor model and Campbell diagrams, which account for mass distribution, stiffness, and damping to identify speeds causing resonance. Both calculations use modal analysis and computational simulations to predict dynamic behavior, ensuring safety and performance in rotating machinery design.

Practical Applications in Engineering and Machinery Design

Resonant frequency refers to the natural frequency at which a system oscillates with maximum amplitude, critical for avoiding excessive vibrations in machinery components such as rotating shafts and beams. Critical speed is the rotational speed at which an object, like a rotor or turbine, experiences resonance, potentially causing catastrophic failure if not properly managed. Engineers design machinery by identifying these frequencies through modal analysis and dynamic testing to ensure safe operational speeds and enhance longevity in turbines, compressors, and automotive engines.

Common Problems Related to Resonance and Critical Speed

Resonant frequency causes excessive vibrations when the system's natural frequency matches the excitation frequency, leading to structural fatigue and potential failure. Critical speed occurs when rotating machinery reaches a specific speed causing instability and increased amplitude of shaft deflections, resulting in bearing damage and misalignment. Common problems include amplified vibrations, noise, accelerated wear, and potential catastrophic breakdowns in mechanical systems.

Strategies for Mitigating Resonance and Critical Speed Issues

Mitigating resonance and critical speed issues in rotating machinery involves tuning operational speeds away from natural frequencies and critical speeds to prevent excessive vibration. Implementing vibration dampers, isolators, and balancing techniques reduces amplitude build-up during resonance, enhancing machine stability. Structural modifications and real-time monitoring systems further aid in identifying and controlling conditions to avoid resonance-induced failures and critical speed-related damage.

Resonant frequency Infographic

libterm.com

libterm.com