Reciprocating compressors utilize pistons driven by a crankshaft to compress gases efficiently in various industrial applications. Their design allows precise control over pressure and flow rate, making them ideal for processes requiring high-pressure air or gas delivery. Explore the rest of the article to understand how your choice of reciprocating compressor can optimize performance and reliability.

Table of Comparison

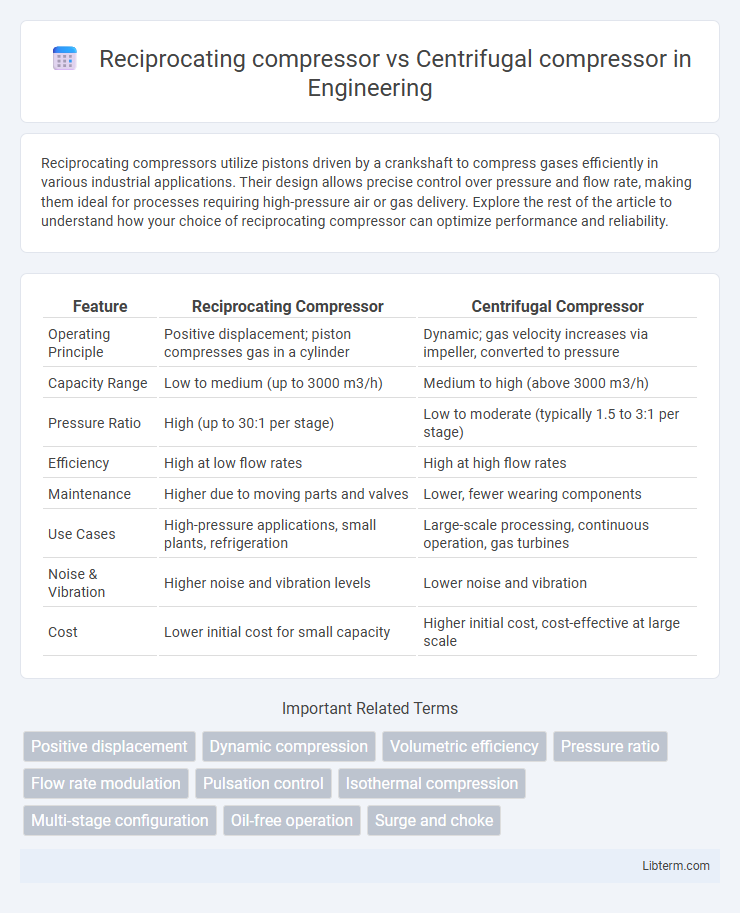

| Feature | Reciprocating Compressor | Centrifugal Compressor |

|---|---|---|

| Operating Principle | Positive displacement; piston compresses gas in a cylinder | Dynamic; gas velocity increases via impeller, converted to pressure |

| Capacity Range | Low to medium (up to 3000 m3/h) | Medium to high (above 3000 m3/h) |

| Pressure Ratio | High (up to 30:1 per stage) | Low to moderate (typically 1.5 to 3:1 per stage) |

| Efficiency | High at low flow rates | High at high flow rates |

| Maintenance | Higher due to moving parts and valves | Lower, fewer wearing components |

| Use Cases | High-pressure applications, small plants, refrigeration | Large-scale processing, continuous operation, gas turbines |

| Noise & Vibration | Higher noise and vibration levels | Lower noise and vibration |

| Cost | Lower initial cost for small capacity | Higher initial cost, cost-effective at large scale |

Introduction to Reciprocating and Centrifugal Compressors

Reciprocating compressors operate using pistons driven by a crankshaft to compress gases in discrete volumes, making them ideal for high-pressure applications and small to medium flow rates. Centrifugal compressors utilize a rotating impeller to impart kinetic energy to the gas, converting it to pressure through diffuser vanes, suited for high flow rates and continuous operation. Both compressor types serve critical roles in industries like oil and gas, refrigeration, and chemical processing, with selection based on pressure, flow requirements, and operational efficiency.

Working Principles: Reciprocating vs Centrifugal Compressors

Reciprocating compressors operate by using pistons driven by a crankshaft to compress gas within cylinders, delivering high-pressure output through positive displacement mechanics. Centrifugal compressors rely on an impeller rotating at high speeds to impart kinetic energy to the gas, which is then converted into increased pressure via diffusion, making them ideal for continuous, high-flow applications. The fundamental difference lies in reciprocating compressors' pulsating compression cycles versus the smooth, dynamic compression process of centrifugal compressors.

Key Components Comparison

Reciprocating compressors feature key components such as pistons, cylinders, valves, and crankshafts, designed for positive displacement and high-pressure applications. Centrifugal compressors utilize impellers, diffusers, and volutes to increase air velocity and convert it to pressure, suitable for continuous, high-flow operations. The mechanical complexity and maintenance requirements differ significantly, with reciprocating compressors requiring more frequent upkeep due to multiple moving parts compared to the streamlined design of centrifugal compressors.

Performance Efficiency Analysis

Reciprocating compressors typically offer high volumetric efficiency and pressure ratios, making them suitable for low to medium flow rates and high-pressure applications, with typical isentropic efficiency ranging from 80% to 90%. Centrifugal compressors excel in handling high flow rates at moderate pressure ratios, often achieving isentropic efficiencies between 85% and 92%, benefiting from continuous operation and fewer moving parts. Performance efficiency analysis reveals that reciprocating compressors have higher energy consumption per unit volume at large scales, whereas centrifugal compressors provide better overall efficiency and lower maintenance costs in industrial gas processing.

Pressure and Flow Rate Capabilities

Reciprocating compressors excel in generating high pressures, often exceeding 3000 psi, making them suitable for applications requiring low to medium flow rates. Centrifugal compressors are optimized for high flow rates, typically in the range of several thousand cubic feet per minute (CFM), but operate efficiently at lower pressure ratios, usually below 10:1. The choice between reciprocating and centrifugal compressors depends primarily on the desired balance between maximum pressure output and volumetric flow capacity.

Maintenance and Reliability Factors

Reciprocating compressors require frequent maintenance due to multiple moving parts such as pistons, valves, and rings that experience wear and tear, making them less reliable for continuous operation. Centrifugal compressors feature fewer moving components and utilize magnetic or hydrodynamic bearings, resulting in higher reliability and reduced maintenance intervals. Predictive maintenance strategies using vibration analysis and real-time monitoring systems improve the operational lifespan of centrifugal compressors compared to the more maintenance-intensive reciprocating types.

Energy Consumption and Operating Costs

Reciprocating compressors typically consume more energy due to their intermittent operation and mechanical complexity, leading to higher operating costs in maintenance and energy usage. Centrifugal compressors offer continuous flow with higher efficiency, which generally results in lower energy consumption and reduced operating expenses over time. Choosing between the two depends on the application's demand for capacity, pressure, and operational efficiency.

Industrial Applications and Suitability

Reciprocating compressors excel in industrial applications requiring high pressure and intermittent operation, such as natural gas processing, chemical plants, and refrigeration systems due to their positive displacement design and ability to handle varying flow rates. Centrifugal compressors are more suitable for continuous, high flow applications including petrochemical refineries, HVAC systems, and large-scale power generation, offering efficiency at steady-state conditions with lower maintenance needs. The choice depends on factors like required pressure, flow stability, operational cost, and maintenance frequency, making reciprocating compressors ideal for high-pressure, low-flow scenarios and centrifugal compressors preferable for high-flow, moderate-pressure applications.

Advantages and Disadvantages of Each Compressor

Reciprocating compressors offer high-pressure output and precise capacity control, making them ideal for applications requiring intermittent, high-pressure delivery; however, they have higher maintenance costs and generate more noise and vibration compared to centrifugal compressors. Centrifugal compressors provide continuous, high-flow rates with greater efficiency and smoother operation, benefiting large-scale industrial processes, but they struggle with handling high-pressure ratios per stage and are less effective for variable load conditions. Selecting between reciprocating and centrifugal compressors depends on factors like required pressure, flow rate, efficiency, operational costs, and maintenance capabilities.

Choosing the Right Compressor for Your Needs

Selecting the right compressor depends on the specific application requirements such as pressure, flow rate, and efficiency. Reciprocating compressors excel in high-pressure, low-flow applications with precise control, while centrifugal compressors are ideal for high-flow, continuous operation with lower maintenance. Evaluating factors like operational costs, space constraints, and performance characteristics ensures optimal compressor selection tailored to industrial or commercial needs.

Reciprocating compressor Infographic

libterm.com

libterm.com