Warping distorts an image or object by altering its shape, often used in graphic design and digital art to create dynamic and visually engaging effects. Techniques like mesh warping or perspective warping allow precise control over bending and stretching elements without compromising quality. Explore the rest of the article to understand how warping can enhance your creative projects.

Table of Comparison

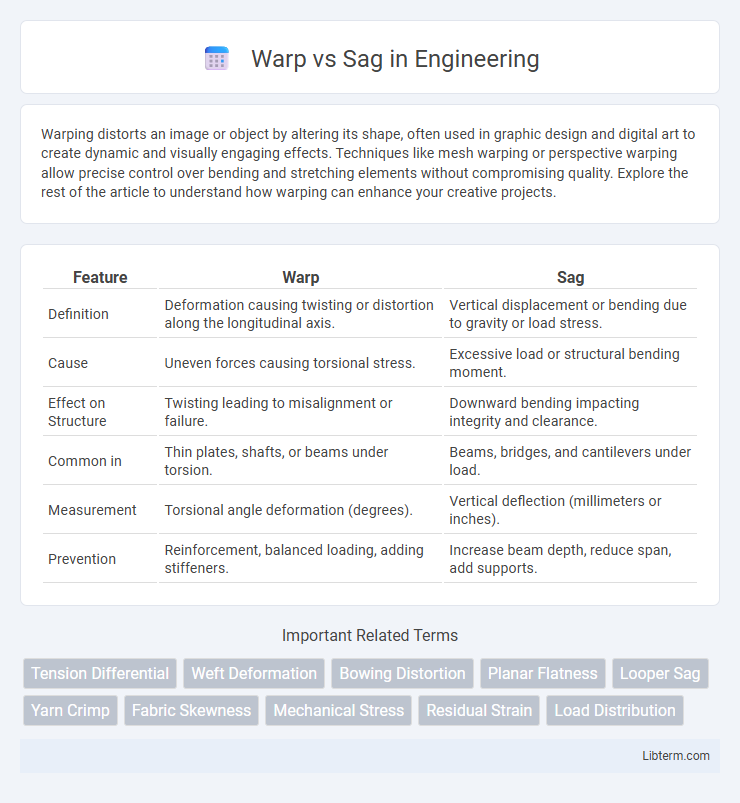

| Feature | Warp | Sag |

|---|---|---|

| Definition | Deformation causing twisting or distortion along the longitudinal axis. | Vertical displacement or bending due to gravity or load stress. |

| Cause | Uneven forces causing torsional stress. | Excessive load or structural bending moment. |

| Effect on Structure | Twisting leading to misalignment or failure. | Downward bending impacting integrity and clearance. |

| Common in | Thin plates, shafts, or beams under torsion. | Beams, bridges, and cantilevers under load. |

| Measurement | Torsional angle deformation (degrees). | Vertical deflection (millimeters or inches). |

| Prevention | Reinforcement, balanced loading, adding stiffeners. | Increase beam depth, reduce span, add supports. |

Introduction to Warp and Sag

Warp refers to the vertical threads held stationary in a weaving loom, forming the foundation of a fabric. Sag describes the unwanted looseness or drooping in the warp threads during weaving, which can affect tension and fabric quality. Proper management of warp tension minimizes sag, ensuring a consistent and durable textile structure.

Definitions: What are Warp and Sag?

Warp refers to the twisting or distortion of a material or surface caused by uneven stress, temperature changes, or moisture exposure, resulting in deviation from its original flat or intended shape. Sag is the downward bending or drooping of a structural element due to gravitational forces, excessive load, or material deformation, leading to a concave curve along the length of the component. Both warp and sag affect the structural integrity and performance of materials, with warp primarily involving torsional deformation while sag involves vertical displacement.

Causes of Warp and Sag

Warp occurs due to uneven moisture absorption, temperature fluctuations, and residual stresses within materials, causing distortion and bending along their surfaces. Sag arises from gravitational forces acting on materials with insufficient structural support or rigidity, leading to downward deformation over time. Both warp and sag are influenced by material composition, thickness, and environmental conditions such as humidity and temperature.

Key Differences Between Warp and Sag

Warp refers to the distortion of material fibers causing a twist or bow, primarily due to uneven moisture or heat exposure, while sag is the downward drooping caused by gravity or insufficient support over time. Warp commonly affects flat surfaces like wooden panels or fabric, altering shape and structure, whereas sag is often seen in suspended elements such as ceilings, beams, or soft materials losing firmness. Key differences include the cause, with warp resulting from internal stress and sag from external load, and their impact on functionality, as warp impairs alignment and sag compromises load-bearing capacity.

Impact of Warp and Sag on Materials

Warp causes deformation in materials due to uneven internal stresses, leading to bending or twisting that compromises structural integrity and dimensional accuracy. Sag results from continuous gravitational or mechanical forces, causing materials to bend or droop over time, reducing load-bearing capacity and potentially leading to material failure. Both warp and sag adversely affect the mechanical properties and lifespan of materials used in construction, manufacturing, and aerospace applications.

Detection and Measurement Techniques

Warp and sag in materials are detected using distinct measurement techniques tailored to their deformation characteristics. Warp is often assessed through optical profilometry and laser scanning, which provide high-resolution surface topography capturing localized out-of-plane deviations. Sag measurement typically employs dial gauges or displacement sensors that quantify vertical deflections over a span, crucial for evaluating load-induced bending in beams or panels.

Preventive Measures for Warp and Sag

Preventive measures for warp include maintaining consistent moisture levels, using kiln-dried lumber, and proper acclimatization of wood before installation to reduce internal stresses. To prevent sag, ensure adequate joist spacing, use stronger or thicker support materials, and install proper load-bearing beams to evenly distribute weight. Regular structural inspections and timely reinforcement help mitigate both warp and sag in wooden constructions.

Industry Applications Affected by Warp and Sag

Warp and sag significantly impact industry applications such as electronics manufacturing, where precision in component alignment and flatness is critical to ensure functionality and reliability. In aerospace and automotive sectors, warped or sagged materials can lead to structural weaknesses, affecting safety and performance standards. The semiconductor industry faces yield reductions and increased defect rates due to warp and sag during wafer processing, emphasizing the importance of material stability in high-precision environments.

Case Studies: Real-World Examples

Case studies comparing Warp and Sag reveal distinct performance dynamics in network acceleration, where Warp consistently reduces latency by up to 30% in distributed applications, enhancing user experience in gaming and video streaming platforms. Sag demonstrates superior reliability in high-traffic environments, maintaining stable connections with minimal packet loss across enterprise VPNs. Real-world deployments highlight Warp's edge in speed optimization, while Sag excels in network resilience and security under heavy loads.

Conclusion: Choosing the Right Approach

Selecting between warp and sag depends on the specific requirements of your project and the material properties involved. Warp techniques offer precision in correcting geometric distortions, ideal for digital imaging and fabric adjustments, while sag methods address gravitational or load-induced deformations found in structural engineering and material science. Evaluating factors such as application context, desired accuracy, and environmental conditions ensures the optimal choice for maintaining integrity and performance.

Warp Infographic

libterm.com

libterm.com