A pressuremeter is an essential geotechnical tool used to measure the deformation and stress-strain behavior of soils in situ, providing accurate data for foundation design and earthwork stability. This device offers reliable insights into soil strength and elasticity, enabling engineers to assess the bearing capacity and settlement potential of ground conditions. Explore the rest of the article to understand how your projects can benefit from pressuremeter testing and its practical applications.

Table of Comparison

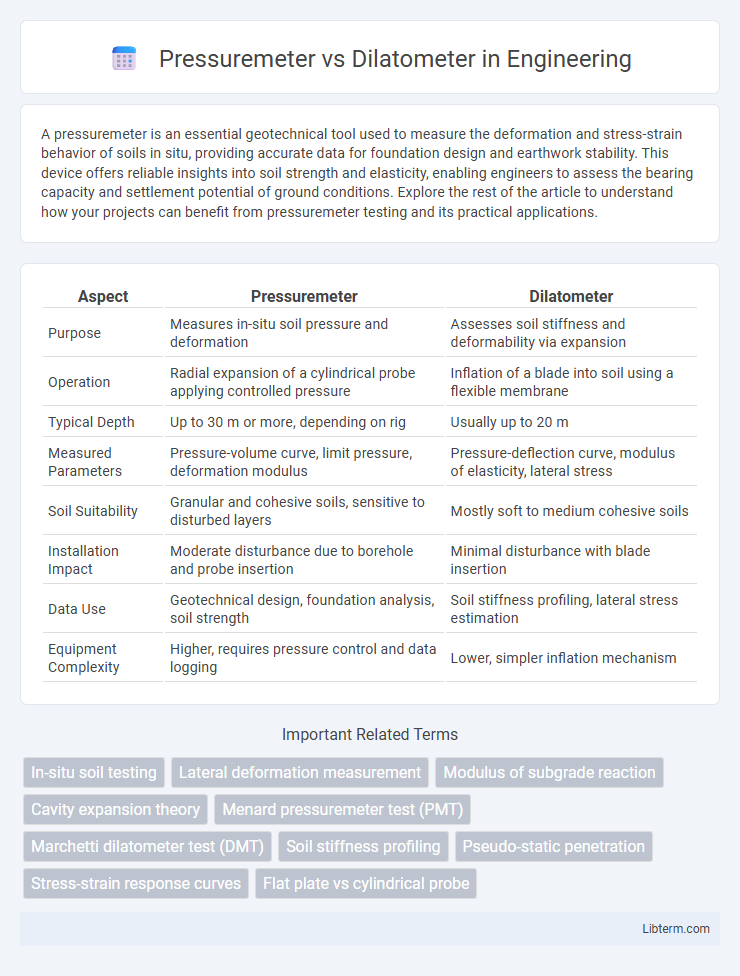

| Aspect | Pressuremeter | Dilatometer |

|---|---|---|

| Purpose | Measures in-situ soil pressure and deformation | Assesses soil stiffness and deformability via expansion |

| Operation | Radial expansion of a cylindrical probe applying controlled pressure | Inflation of a blade into soil using a flexible membrane |

| Typical Depth | Up to 30 m or more, depending on rig | Usually up to 20 m |

| Measured Parameters | Pressure-volume curve, limit pressure, deformation modulus | Pressure-deflection curve, modulus of elasticity, lateral stress |

| Soil Suitability | Granular and cohesive soils, sensitive to disturbed layers | Mostly soft to medium cohesive soils |

| Installation Impact | Moderate disturbance due to borehole and probe insertion | Minimal disturbance with blade insertion |

| Data Use | Geotechnical design, foundation analysis, soil strength | Soil stiffness profiling, lateral stress estimation |

| Equipment Complexity | Higher, requires pressure control and data logging | Lower, simpler inflation mechanism |

Introduction to In-Situ Soil Testing Methods

Pressuremeter and dilatometer tests are essential in-situ soil testing methods used to determine soil deformation and strength characteristics directly within the ground. The pressuremeter test measures soil response by expanding a cylindrical probe against the borehole wall, providing data on pressure-volume relationships and soil stiffness. The dilatometer test utilizes a flat blade inserted into the soil to gauge lateral soil pressure and moduli, offering rapid assessment of soil stratigraphy and shear strength parameters.

Overview of Pressuremeter Testing

Pressuremeter testing measures in-situ soil deformability and strength by expanding a cylindrical probe in a borehole, providing detailed load-deformation curves essential for geotechnical design. The test captures parameters such as limit pressure, modulus of deformation, and creep behavior, aiding in accurate assessment of soil stress-strain characteristics. Compared to dilatometer tests, pressuremeter offers direct measurement of lateral soil pressures and better results in layered or stiff soil conditions.

Fundamentals of Dilatometer Testing

Dilatometer testing involves inserting a flat, circular membrane into a borehole and expanding it to measure soil deformation and in-situ stress, providing continuous profiles of soil stiffness and stress-strain behavior. Unlike pressuremeter testing, which uses a cylindrical probe to apply radial pressure, dilatometer tests offer higher resolution data with simpler equipment and quicker deployment in soft to medium cohesive soils. This method is fundamental for characterizing soil compressibility, shear strength, and lateral earth pressures critical for geotechnical design and foundation assessments.

Equipment and Setup Differences

Pressuremeters feature cylindrical probes inserted into boreholes to measure soil deformation under radial expansion, requiring a sealed testing environment and hydraulic or pneumatic inflation systems. Dilatometers use flat, blade-like probes with an expandable membrane pressed laterally against the soil, often requiring shallower insertion and simpler inflation mechanisms. Equipment differences impact setup complexity: pressuremeter tests need borehole stabilization and precise depth control, while dilatometers allow quicker deployment with minimal borehole preparation.

Principles of Operation: Pressuremeter vs Dilatometer

The pressuremeter operates by inserting a cylindrical probe into a borehole and expanding it to measure soil deformation and pressure response, providing in-situ stress-strain characteristics. In contrast, the dilatometer utilizes a flat blade with an inflatable membrane that expands laterally against the soil, allowing indirect assessment of soil stiffness and lateral stress. Both devices deliver critical geotechnical data, yet the pressuremeter directly measures radial soil pressure while the dilatometer infers soil properties from membrane expansion and pressure profiles.

Data Interpretation and Parameter Outcomes

Pressuremeter tests provide direct measurements of soil deformation and stress response, enabling detailed calculation of soil parameters such as limit pressure, modulus of elasticity, and lateral earth pressure coefficients. Dilatometer tests offer continuous profiles of soil stiffness and lateral stress, yielding parameters like the material index, horizontal stress index, and dilatometer modulus, which correlate well with in-situ soil behavior. Data interpretation from pressuremeters emphasizes stress-strain relationships, while dilatometers excel in providing integrated stiffness and stress distribution, making both indispensable for comprehensive geotechnical analysis.

Applications in Geotechnical Engineering

Pressuremeters are primarily used in geotechnical engineering to measure in-situ soil pressure and deformation characteristics, providing critical data for foundation design and assessing soil strength. Dilatometers serve similarly but excel in determining soil modulus and stress-strain behavior, offering precise measurements for site characterization and settlement analysis. Both tools enhance soil investigation accuracy, with pressuremeters favored for deeper, cohesive soils and dilatometers preferred in softer, granular soil profiles.

Advantages and Limitations: Comparative Analysis

Pressuremeter testing provides direct measurement of soil deformation under controlled pressure, offering precise data on in-situ soil stiffness and strength parameters critical for foundation design. Dilatometer testing yields rapid soil profiling with minimal soil disturbance, enabling detailed stratigraphic delineation and reliable estimates of lateral stress and modulus values, yet it may be less effective in very stiff or gravelly soils. While pressuremeters excel in obtaining accurate stress-strain curves for complex analyses, their deployment can be more time-consuming and costly compared to the simpler, quicker dilatometer method, which is limited by its reduced effectiveness in heterogeneous ground conditions.

Site Conditions Best Suited for Each Method

The pressuremeter is most effective in stable, granular soils and weak rock formations where controlled radial expansion can accurately measure soil stiffness and strength parameters. The dilatometer excels in soft to medium cohesive soils with low permeability, providing precise measurements of lateral soil stress and deformation due to its flat blade design and hydraulic membrane expansion. Site conditions with high groundwater levels and soft clays benefit from dilatometer testing, while dense sands and stiff soils are better suited for pressuremeter investigations.

Cost, Efficiency, and Practical Considerations

Pressuremeters generally incur higher costs due to their complex equipment and longer testing time compared to dilatometers, which use simpler, more cost-effective devices. Efficiency in field operations favors dilatometers because they provide rapid, easy-to-interpret results with less soil disturbance, whereas pressuremeters offer detailed soil behavior data but require more expertise and time. Practical considerations include the choice of tool based on project scale and soil type, with dilatometers preferred for routine site characterization and pressuremeters reserved for detailed geotechnical analysis where precise soil deformation properties are critical.

Pressuremeter Infographic

libterm.com

libterm.com