Pressurized pipes are engineered to withstand high internal pressures, ensuring safe and efficient transport of liquids and gases across various industries. Their design involves materials and construction methods that prevent leaks, bursts, and failures under extreme conditions. Discover how pressurized pipes impact your infrastructure and the key factors to consider by reading the rest of the article.

Table of Comparison

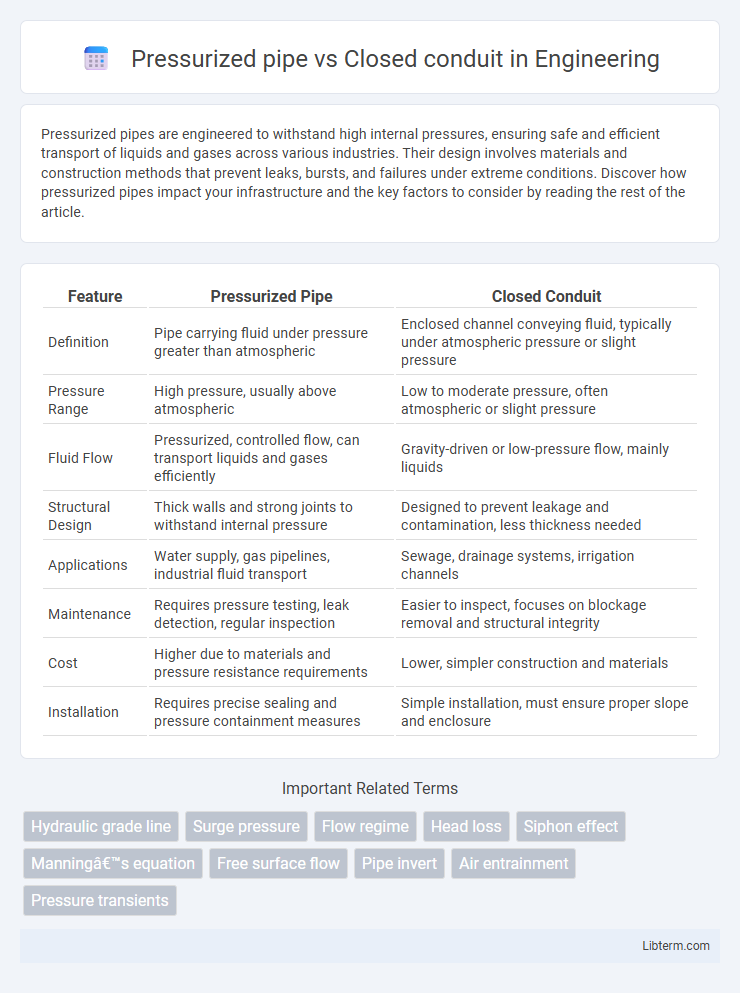

| Feature | Pressurized Pipe | Closed Conduit |

|---|---|---|

| Definition | Pipe carrying fluid under pressure greater than atmospheric | Enclosed channel conveying fluid, typically under atmospheric pressure or slight pressure |

| Pressure Range | High pressure, usually above atmospheric | Low to moderate pressure, often atmospheric or slight pressure |

| Fluid Flow | Pressurized, controlled flow, can transport liquids and gases efficiently | Gravity-driven or low-pressure flow, mainly liquids |

| Structural Design | Thick walls and strong joints to withstand internal pressure | Designed to prevent leakage and contamination, less thickness needed |

| Applications | Water supply, gas pipelines, industrial fluid transport | Sewage, drainage systems, irrigation channels |

| Maintenance | Requires pressure testing, leak detection, regular inspection | Easier to inspect, focuses on blockage removal and structural integrity |

| Cost | Higher due to materials and pressure resistance requirements | Lower, simpler construction and materials |

| Installation | Requires precise sealing and pressure containment measures | Simple installation, must ensure proper slope and enclosure |

Understanding Pressurized Pipes and Closed Conduits

Pressurized pipes are designed to transport fluids under pressure, ensuring a continuous flow regardless of gravity, commonly used in water supply and industrial applications. Closed conduits, including pipes and ducts, fully enclose the fluid and can operate under pressure or gravity flow but prevent exposure to the external environment and contamination. Understanding the distinction involves recognizing that all pressurized pipes are closed conduits, but not all closed conduits maintain pressure, impacting their design, material choice, and function in fluid transport systems.

Key Differences Between Pressurized Pipes and Closed Conduits

Pressurized pipes transport fluids under pressure greater than atmospheric, enabling flow through elevation changes and long distances without gravity reliance, while closed conduits typically operate at or below atmospheric pressure, relying on gravity flow. Pressurized pipes require sealing to withstand internal pressure, unlike closed conduits which may allow air in and out to regulate pressure. The construction materials and thickness for pressurized pipes are designed for strength to resist bursting, whereas closed conduits prioritize flow capacity and minimal friction losses.

Functional Principles of Pressurized Pipes

Pressurized pipes operate by maintaining internal pressure higher than atmospheric levels, enabling fluid transport regardless of elevation changes, unlike closed conduits which typically rely on gravity flow. These pipes utilize sealed, rigid structures designed to withstand high internal pressures, ensuring continuous and controlled fluid movement within municipal water systems, industrial applications, and irrigation networks. Flow dynamics in pressurized pipes are governed by pressure gradients, pump operations, and pipe material strength, facilitating efficient distribution and minimizing leakage.

How Closed Conduits Operate

Closed conduits operate by channeling fluids within fully enclosed pipes or tunnels, allowing for controlled pressure and flow without exposure to external environmental factors. This system relies on the pipe's structural integrity to withstand internal pressure, ensuring efficient transport of liquids or gases over long distances. The pressurized environment in closed conduits minimizes leakage and contamination, optimizing hydraulic performance compared to open or partially open systems.

Material Selection: Pressurized Pipe vs Closed Conduit

Material selection for pressurized pipes prioritizes high-strength metals like steel, ductile iron, or reinforced thermoplastics to withstand internal pressure and prevent rupture. Closed conduits often use non-pressurized materials such as concrete, PVC, or corrugated steel designed primarily for protection and structural support rather than pressure resistance. The choice depends on load requirements, fluid properties, and environmental conditions, with pressurized pipes necessitating materials engineered for durability under pressure and closed conduits focusing on robustness and corrosion resistance.

Typical Applications in Modern Infrastructure

Pressurized pipes are commonly used in water supply networks, sewage systems, and industrial fluid transport where controlled flow and high pressure withstand are essential. Closed conduits typically serve as stormwater drains, culverts, and irrigation channels, designed to manage gravity flow without pressure buildup. Modern infrastructure often integrates pressurized pipes for reliability in urban water distribution, while closed conduits facilitate efficient drainage and flood prevention.

Advantages of Pressurized Pipe Systems

Pressurized pipe systems offer the advantage of transporting fluids over long distances with consistent flow rates and controlled pressure, reducing the risk of contamination and leakage compared to closed conduit systems. They enable efficient water distribution in urban and industrial applications by maintaining hydraulic pressure, facilitating the use of smaller diameter pipes and minimizing land use. The ability to operate under pressure also supports better system flexibility and easier integration with pumps and valves for precise flow management.

Benefits and Limitations of Closed Conduits

Closed conduits offer significant benefits such as protection from environmental damage, reduced leakage, and consistent flow control, making them ideal for urban water supply systems. Their limitations include higher installation costs and maintenance challenges due to the need for airtight seals and resistance to pressure fluctuations. Closed conduits also require careful design to prevent blockages and ensure structural integrity under varying hydraulic loads.

Factors Influencing System Choice

Choosing between pressurized pipes and closed conduits depends significantly on factors like the required flow rate, pressure conditions, and environmental impact. Pressurized pipes are ideal for high-pressure applications and long-distance fluid transport, offering leak prevention and system efficiency. Closed conduits suit gravity-driven flow with lower pressure needs, often used in urban drainage systems where minimizing excavation and cost is essential.

Cost, Maintenance, and Longevity Comparison

Pressurized pipes typically involve higher initial costs due to the need for stronger materials and specialized installation to withstand internal pressure, whereas closed conduits are generally less expensive and simpler to install as they rely on gravity flow. Maintenance for pressurized pipes is more complex and costly, requiring regular pressure testing and corrosion control, while closed conduits usually need less frequent inspection and cleaning because they operate under gravity with no internal pressure. In terms of longevity, pressurized pipes often have a shorter lifespan if not properly maintained due to stress and risk of leaks, whereas closed conduits tend to have longer durability since they experience less mechanical stress and corrosion.

Pressurized pipe Infographic

libterm.com

libterm.com