Proportional-Integral-Derivative (PID) control is a widely used feedback mechanism in industrial automation that continuously calculates an error value as the difference between a desired setpoint and a measured process variable. It adjusts the control inputs to minimize this error by combining proportional, integral, and derivative terms for precise and stable system regulation. Explore this article to understand how PID control can optimize your system's performance and reliability.

Table of Comparison

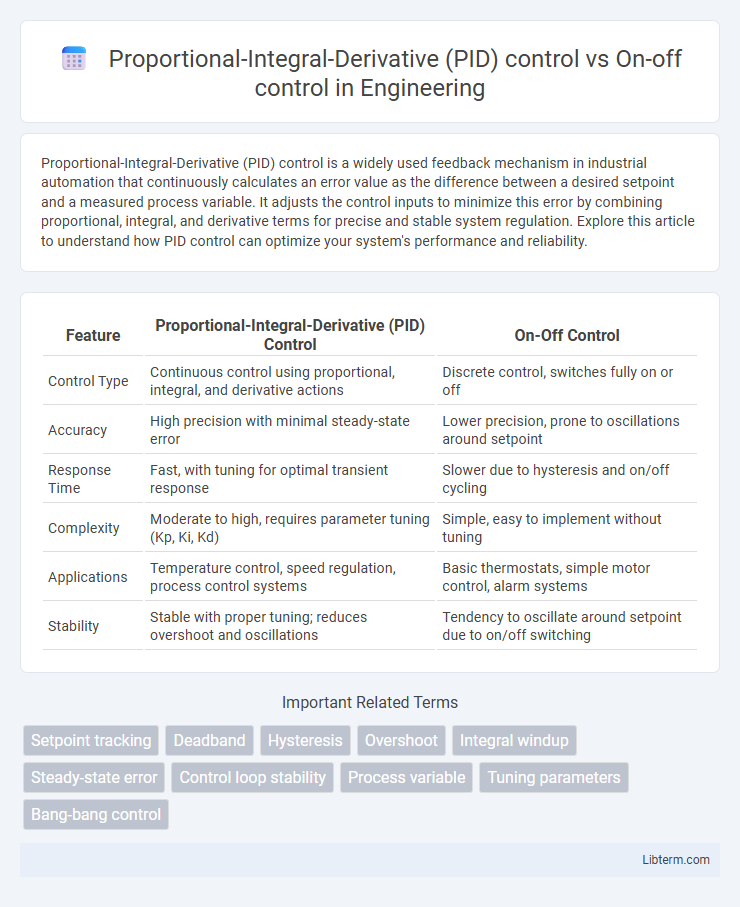

| Feature | Proportional-Integral-Derivative (PID) Control | On-Off Control |

|---|---|---|

| Control Type | Continuous control using proportional, integral, and derivative actions | Discrete control, switches fully on or off |

| Accuracy | High precision with minimal steady-state error | Lower precision, prone to oscillations around setpoint |

| Response Time | Fast, with tuning for optimal transient response | Slower due to hysteresis and on/off cycling |

| Complexity | Moderate to high, requires parameter tuning (Kp, Ki, Kd) | Simple, easy to implement without tuning |

| Applications | Temperature control, speed regulation, process control systems | Basic thermostats, simple motor control, alarm systems |

| Stability | Stable with proper tuning; reduces overshoot and oscillations | Tendency to oscillate around setpoint due to on/off switching |

Introduction to PID and On-Off Control

Proportional-Integral-Derivative (PID) control is a sophisticated feedback mechanism widely used in industrial automation to maintain process variables at desired setpoints by continuously adjusting control inputs based on proportional, integral, and derivative terms. On-off control, a simpler binary method, switches the output fully on or off depending on whether the process variable deviates above or below a threshold, leading to potential oscillations around the setpoint. PID control offers smoother and more precise regulation compared to the abrupt switching behavior of on-off control, making it suitable for systems requiring stable and accurate control responses.

Fundamental Principles of PID Control

Proportional-Integral-Derivative (PID) control continuously adjusts the control input by calculating the error between a desired setpoint and the process variable, based on proportional, integral, and derivative terms to minimize this error. The proportional term provides immediate correction proportional to the error magnitude, the integral term eliminates steady-state error by summing past errors, and the derivative term predicts future errors by considering the rate of change. Unlike On-off control, which switches output fully on or off, PID control enables smoother, more precise regulation by continuously modulating the control signal to enhance system stability and response time.

Basics of On-Off Control Systems

On-off control systems operate by switching the actuator fully on or off based on whether the process variable crosses a set threshold, resulting in simple implementation but potential oscillations. Unlike Proportional-Integral-Derivative (PID) controllers, which provide continuous and precise adjustments by considering error magnitude, accumulation, and rate of change, on-off control lacks smooth modulation and often causes system wear due to frequent switching. This basic control strategy suits applications where simplicity and cost-effectiveness outweigh the need for fine-tuned process regulation.

Key Differences Between PID and On-Off Control

PID control continuously adjusts the control output based on proportional, integral, and derivative terms, offering precise regulation and minimizing steady-state error. In contrast, on-off control operates by switching the output fully on or off, resulting in simpler implementation but causing oscillations and less stability around the setpoint. Key differences include PID's ability to handle complex dynamic systems with smooth control responses, while on-off control suits basic applications requiring binary control actions without fine tuning.

Performance Comparison: Accuracy and Stability

Proportional-Integral-Derivative (PID) control offers superior accuracy and stability compared to On-off control by continuously adjusting the control output based on error magnitude, integral of past errors, and prediction of future errors. On-off control frequently causes oscillations and overshoot due to its binary switching nature, leading to lower precision and potential system wear. PID control's smooth and adaptive response enhances performance in systems requiring precise regulation and minimizes steady-state error, ensuring stable operation across various dynamic conditions.

Application Areas for PID vs On-Off Control

PID control excels in applications requiring precise and continuous regulation, such as temperature control in industrial furnaces, motor speed control in robotics, and process industries like chemical manufacturing. On-off control is commonly used in simpler systems where only two states are needed, such as household thermostats, water heaters, and basic lighting controls. The ability of PID control to minimize steady-state error and handle dynamic system changes makes it ideal for complex automated processes, while on-off control suits applications with less stringent precision and slower system response requirements.

Advantages and Limitations of PID Controllers

PID controllers provide precise control by continuously adjusting output based on proportional, integral, and derivative terms, reducing steady-state error and improving system stability. They handle complex dynamic systems more effectively compared to on-off control, which only switches states and can cause oscillations and wear in mechanical components. Limitations of PID controllers include sensitivity to tuning parameters and potential instability if gains are not properly set, requiring expert knowledge or adaptive algorithms for optimal performance.

Advantages and Limitations of On-Off Controllers

On-off controllers offer simplicity and ease of implementation, making them cost-effective for applications requiring basic control without the need for continuous variability. Their main limitation lies in the inherent oscillations around the setpoint, which can lead to wear on mechanical components and reduced precision in temperature or process regulation. In contrast to PID controllers, on-off controllers lack the ability to modulate output smoothly, resulting in less stable and less accurate control performance.

Tuning and Implementation Considerations

Proportional-Integral-Derivative (PID) control requires precise tuning of its three parameters (proportional gain, integral time, and derivative time) to achieve optimal system performance, often using methods like Ziegler-Nichols or software-based optimization. On-off control, by contrast, involves simpler implementation with binary output states but may cause oscillations and wear due to frequent switching, making it less suitable for systems demanding smooth regulation. PID controllers demand continuous monitoring and adjustments during implementation to handle system nonlinearities and disturbances, whereas on-off controllers excel in applications with less stringent precision and stability requirements.

Choosing the Right Control Strategy

Choosing the right control strategy between Proportional-Integral-Derivative (PID) control and On-off control depends on the system's complexity and precision requirements. PID control offers continuous, fine-tuned adjustments by calculating error values and applying proportional, integral, and derivative corrections, making it ideal for processes requiring stable, accurate control such as temperature regulation and motor speed control. On-off control suits simpler applications with binary states, providing cost-effective and straightforward operation for devices like thermostats and level controllers where precision is less critical.

Proportional-Integral-Derivative (PID) control Infographic

libterm.com

libterm.com