Needle peening is a precise surface treatment process that uses small, hardened needles to improve the fatigue strength and durability of metal components by inducing beneficial compressive stresses. This technique effectively reduces surface cracks and enhances resistance to wear and corrosion in parts such as automotive springs or aircraft components. Explore the benefits and applications of needle peening to understand how your materials can achieve longer service life.

Table of Comparison

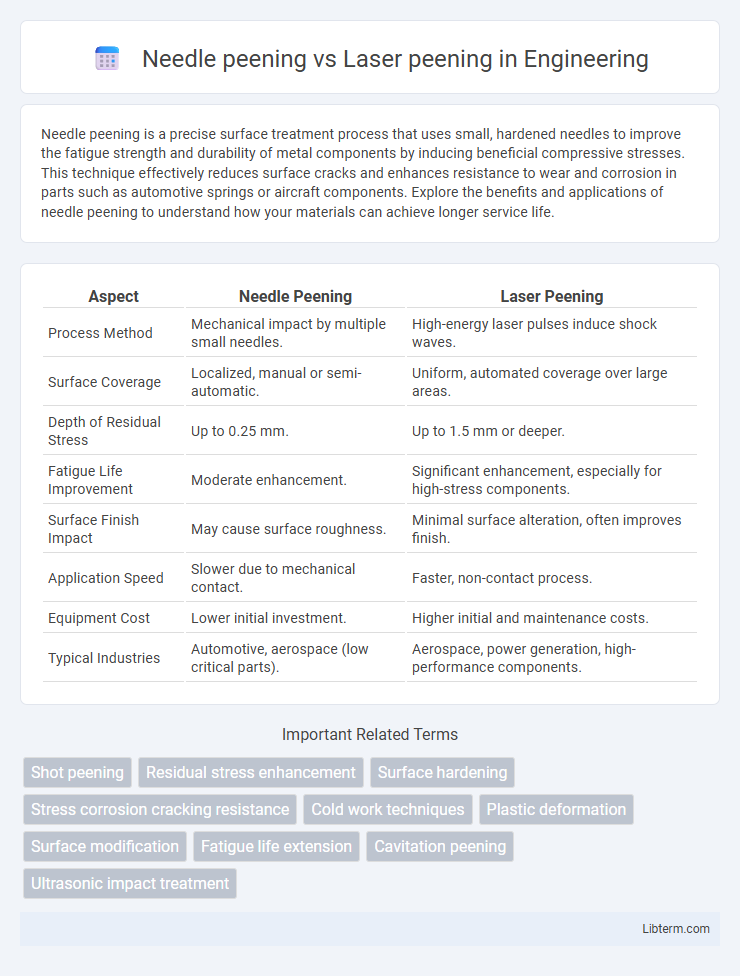

| Aspect | Needle Peening | Laser Peening |

|---|---|---|

| Process Method | Mechanical impact by multiple small needles. | High-energy laser pulses induce shock waves. |

| Surface Coverage | Localized, manual or semi-automatic. | Uniform, automated coverage over large areas. |

| Depth of Residual Stress | Up to 0.25 mm. | Up to 1.5 mm or deeper. |

| Fatigue Life Improvement | Moderate enhancement. | Significant enhancement, especially for high-stress components. |

| Surface Finish Impact | May cause surface roughness. | Minimal surface alteration, often improves finish. |

| Application Speed | Slower due to mechanical contact. | Faster, non-contact process. |

| Equipment Cost | Lower initial investment. | Higher initial and maintenance costs. |

| Typical Industries | Automotive, aerospace (low critical parts). | Aerospace, power generation, high-performance components. |

Introduction to Peening Techniques

Needle peening and laser peening are advanced surface enhancement techniques used to improve metal fatigue strength and resistance to stress corrosion cracking. Needle peening employs a cluster of fine needles mechanically impacting the surface, creating localized plastic deformation and compressive residual stresses. Laser peening uses high-energy laser pulses to generate shock waves that induce deeper compressive stresses and enhance the longevity of critical components in aerospace and automotive industries.

What is Needle Peening?

Needle peening is a mechanical surface treatment that improves metal fatigue resistance by impacting the material with a bundle of small, hardened needles at high frequency, creating compressive residual stresses. This process refines surface microstructure, reduces tensile stresses, and enhances crack initiation resistance in components such as turbine blades and automotive parts. Unlike laser peening, which uses high-energy laser pulses, needle peening relies solely on mechanical indentation for surface hardening and stress relief.

What is Laser Peening?

Laser peening is a surface enhancement technology that uses high-energy laser pulses to induce deep compressive residual stresses in metal components, significantly improving fatigue strength and resistance to stress corrosion cracking. Unlike needle peening, which relies on mechanical impact from fine needles to create beneficial stresses near the surface, laser peening delivers precise and deeper treatment without direct contact, enabling superior performance in critical aerospace, automotive, and power generation parts. This innovative method can penetrate several millimeters beneath the surface, offering enhanced durability and extended service life for high-stress metal alloys.

Mechanisms of Surface Modification

Needle peening modifies surfaces by delivering controlled mechanical impacts through fine needles, inducing plastic deformation and compressive residual stresses to enhance fatigue resistance. Laser peening employs high-energy laser pulses to generate shock waves that produce deeper and more uniform compressive residual stresses, significantly improving surface hardness and resistance to stress corrosion cracking. The primary difference in mechanisms lies in needle peening's mechanical impact versus laser peening's shock-induced plastic deformation, resulting in varied depth and intensity of surface modifications.

Key Differences Between Needle and Laser Peening

Needle peening uses mechanical impact via multiple steel needles to induce surface compressive stress, while laser peening employs high-energy laser pulses to generate plasma shock waves for deeper residual stress penetration. Laser peening typically achieves greater depth of compressive stress, enhancing fatigue resistance more effectively than needle peening's surface-focused treatment. Cost, precision, and application scale also differ: needle peening is more economical and suited for localized areas, whereas laser peening demands specialized equipment and is preferred for high-performance aerospace and automotive components.

Advantages of Needle Peening

Needle peening offers precise control over surface compression, making it highly effective for stress relief in complex geometries and localized areas. This mechanical process enhances fatigue strength by inducing beneficial compressive residual stresses without the need for expensive equipment or extensive setup times. Compared to laser peening, needle peening is more cost-efficient and adaptable to diverse industrial applications such as aerospace and automotive component manufacturing.

Advantages of Laser Peening

Laser peening offers superior benefits over needle peening by inducing deeper compressive residual stresses, resulting in enhanced fatigue strength and resistance to stress corrosion cracking in metals such as titanium, aluminum, and steel alloys. The non-contact, precise nature of laser peening enables consistent treatment of complex geometries without surface damage, ensuring improved durability in aerospace and automotive components. Moreover, laser peening's ability to treat hard-to-reach areas with minimal thermal impact extends component life and reduces maintenance costs compared to conventional needle peening methods.

Typical Applications in Industry

Needle peening is commonly applied in the automotive and aerospace industries to enhance fatigue resistance in components such as gears, springs, and landing gear parts through controlled surface compressive stresses. Laser peening is primarily used in high-performance sectors like aerospace and power generation for its deep stress layer capabilities, improving fatigue life in turbine blades, aircraft engine components, and welded structures. Industrial use of laser peening also extends to shipbuilding and nuclear power where precision and minimal distortion are critical for component durability.

Cost and Efficiency Comparison

Needle peening typically incurs lower initial costs due to simpler equipment and reduced maintenance requirements, making it cost-effective for small to medium-scale applications. Laser peening, while involving higher capital investment and operational expenses, delivers superior efficiency through deeper compressive stress layers and faster processing times, enhancing fatigue life and material performance. The choice between needle and laser peening depends on balancing upfront expenditure against long-term benefits in productivity and component durability.

Choosing the Right Peening Method

Needle peening involves mechanically striking the surface to induce compressive stress, making it ideal for small-scale repairs and intricate geometries. Laser peening uses high-energy laser pulses to generate shock waves, offering deeper compressive layers suitable for high-strength aerospace and automotive components. Selecting the right peening method depends on factors such as material type, component size, desired fatigue life improvement, and cost-effectiveness.

Needle peening Infographic

libterm.com

libterm.com