Gate valves provide reliable flow control by lifting a gate out of the fluid path, allowing for minimal pressure loss and tight sealing. Commonly used in pipelines for liquids and gases, they are ideal for fully open or fully closed positions but are not recommended for throttling purposes. Discover how gate valves can optimize your system's efficiency by exploring the detailed functions and applications in the rest of the article.

Table of Comparison

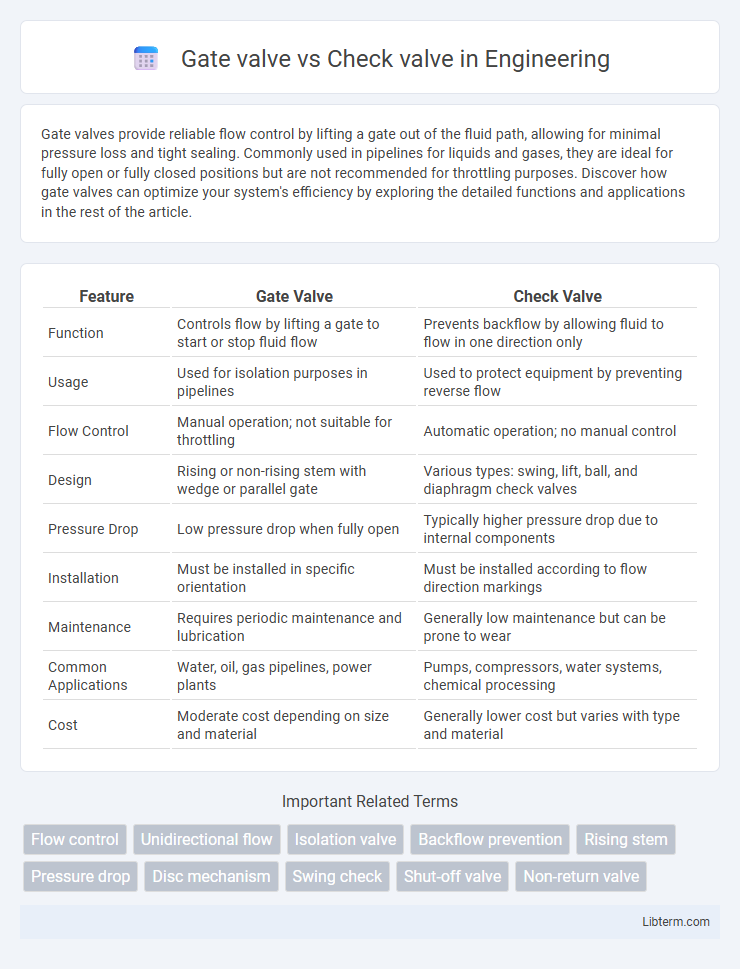

| Feature | Gate Valve | Check Valve |

|---|---|---|

| Function | Controls flow by lifting a gate to start or stop fluid flow | Prevents backflow by allowing fluid to flow in one direction only |

| Usage | Used for isolation purposes in pipelines | Used to protect equipment by preventing reverse flow |

| Flow Control | Manual operation; not suitable for throttling | Automatic operation; no manual control |

| Design | Rising or non-rising stem with wedge or parallel gate | Various types: swing, lift, ball, and diaphragm check valves |

| Pressure Drop | Low pressure drop when fully open | Typically higher pressure drop due to internal components |

| Installation | Must be installed in specific orientation | Must be installed according to flow direction markings |

| Maintenance | Requires periodic maintenance and lubrication | Generally low maintenance but can be prone to wear |

| Common Applications | Water, oil, gas pipelines, power plants | Pumps, compressors, water systems, chemical processing |

| Cost | Moderate cost depending on size and material | Generally lower cost but varies with type and material |

Introduction to Gate Valves and Check Valves

Gate valves operate by lifting a gate out of the flow path, providing a straight-through passage that minimizes pressure drop and is ideal for on/off control in pipelines. Check valves prevent backflow by allowing fluid to flow in only one direction, using mechanisms like swing, lift, or ball types to automatically close when reverse flow occurs. Both valve types play critical roles in fluid control systems, ensuring operational efficiency and system protection in industries such as water treatment, oil and gas, and chemical processing.

Purpose and Functionality Comparison

Gate valves primarily control fluid flow by providing a straight-through passage when fully open, allowing minimal pressure drop, and are ideal for on/off service without throttling. Check valves automatically prevent backflow by allowing fluid to flow in one direction only, using a hinged or spring-loaded mechanism that closes upon reverse flow. While gate valves require manual or actuator operation for opening and closing, check valves function autonomously to protect pumps and pipelines from reverse flow damage.

Structural Differences Explained

Gate valves feature a flat or wedge-shaped gate that moves perpendicular to the flow to start or stop fluid, providing a straight flow path with minimal pressure drop. Check valves incorporate a hinged or spring-loaded disc that swings or lifts to allow flow in one direction and close automatically to prevent backflow. Structural differences include the gate valve's linear motion for on/off control versus the check valve's automatic, flow-driven mechanism designed specifically for backflow prevention.

How Gate Valves Work

Gate valves operate by lifting a flat or wedge-shaped gate out of the flow path, allowing fluid to pass through when fully open and providing a tight seal when closed. They are designed for on/off control rather than throttling, ensuring minimal pressure drop and smooth flow in pipelines. Commonly used in water, oil, and gas industries, gate valves are ideal for applications requiring a straight-line flow with minimal resistance.

How Check Valves Operate

Check valves operate by allowing fluid to flow in one direction and automatically preventing backflow without manual intervention. They rely on internal mechanisms, such as a spring-loaded disc or a swing flap, that move in response to fluid pressure to open or close the valve. Unlike gate valves, which control flow by lifting a gate, check valves function solely to protect piping systems from reverse flow and potential damage.

Applications and Use Cases

Gate valves are primarily used in applications requiring unobstructed flow and minimal pressure drop, such as water supply systems, oil and gas pipelines, and steam services where on/off control is essential. Check valves are designed for preventing backflow in systems like pumps, compressors, and HVAC units, ensuring unidirectional flow and protecting equipment from damage. Both valves are critical in industrial processes, but gate valves are favored for isolation while check valves are essential for flow protection.

Advantages of Gate Valves

Gate valves offer superior flow control with minimal pressure drop, making them ideal for on/off applications in pipelines. Their robust design supports high-pressure and high-temperature environments, ensuring durability and long service life. Unlike check valves, gate valves provide a tight seal when fully closed, preventing leakage and enabling reliable isolation of fluid flow.

Advantages of Check Valves

Check valves provide automatic flow control by allowing fluid to move in only one direction, preventing backflow and potential damage to equipment. They require no manual intervention or external power, enhancing system reliability and reducing maintenance costs. Their ability to operate effectively in various applications, including water, gas, and chemical pipelines, makes them essential for safeguarding pumps, compressors, and other critical components.

Maintenance and Durability Factors

Gate valves require periodic lubrication and stem packing adjustments to maintain optimal performance, with wear primarily occurring on the gate and seat due to frequent operation. Check valves have simpler maintenance needs as they rely on gravity or flow pressure to close, but their durability depends heavily on the hinge, seal, and disc material resisting water hammer and debris damage. Proper selection of materials like stainless steel or resilient rubber seals significantly enhances the lifespan and reduces downtime for both valve types.

Choosing Between Gate Valve and Check Valve

Choosing between a gate valve and a check valve depends on the specific application requirements for flow control and prevention of backflow. Gate valves are ideal for on/off control with minimal pressure drop and are typically used in systems requiring full flow or no flow, such as water supply lines or pipeline isolation. Check valves, designed to automatically prevent reverse flow, are essential in systems where backflow could damage equipment or disrupt operation, including pumps, compressors, and wastewater treatment facilities.

Gate valve Infographic

libterm.com

libterm.com