Fluid film lubrication occurs when a continuous layer of lubricant separates two moving surfaces, minimizing direct contact and reducing friction. This type of lubrication is essential in high-speed machinery where the fluid film supports the load and prevents wear. Discover how fluid film lubrication enhances machinery performance and prolongs equipment life in the rest of this article.

Table of Comparison

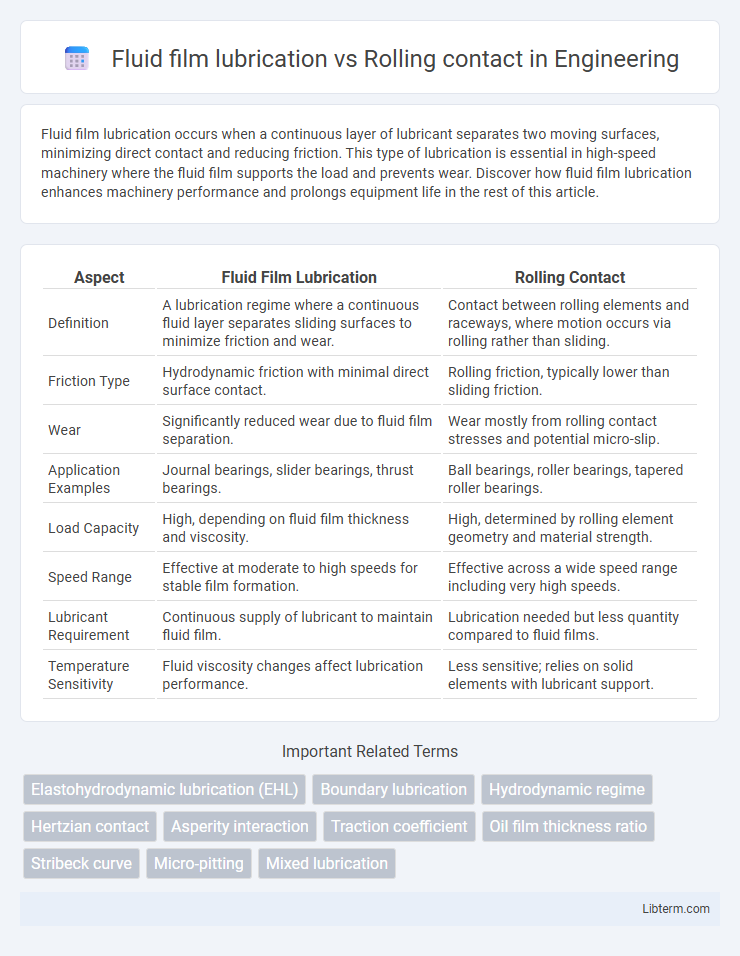

| Aspect | Fluid Film Lubrication | Rolling Contact |

|---|---|---|

| Definition | A lubrication regime where a continuous fluid layer separates sliding surfaces to minimize friction and wear. | Contact between rolling elements and raceways, where motion occurs via rolling rather than sliding. |

| Friction Type | Hydrodynamic friction with minimal direct surface contact. | Rolling friction, typically lower than sliding friction. |

| Wear | Significantly reduced wear due to fluid film separation. | Wear mostly from rolling contact stresses and potential micro-slip. |

| Application Examples | Journal bearings, slider bearings, thrust bearings. | Ball bearings, roller bearings, tapered roller bearings. |

| Load Capacity | High, depending on fluid film thickness and viscosity. | High, determined by rolling element geometry and material strength. |

| Speed Range | Effective at moderate to high speeds for stable film formation. | Effective across a wide speed range including very high speeds. |

| Lubricant Requirement | Continuous supply of lubricant to maintain fluid film. | Lubrication needed but less quantity compared to fluid films. |

| Temperature Sensitivity | Fluid viscosity changes affect lubrication performance. | Less sensitive; relies on solid elements with lubricant support. |

Introduction to Lubrication Mechanisms

Fluid film lubrication forms a continuous lubricant layer that separates contacting surfaces, preventing direct metal-to-metal contact and significantly reducing friction and wear. Rolling contact lubrication, characteristic of bearings and gears, involves lubricant maintaining a thin film within rolling interfaces to minimize surface asperity interaction and dissipate heat. Both mechanisms rely on precise lubricant viscosity and film thickness to optimize machine performance and extend component lifespan.

Fundamentals of Fluid Film Lubrication

Fluid film lubrication relies on a continuous, pressurized lubricating film that separates sliding surfaces, minimizing direct metal-to-metal contact and reducing friction and wear. This lubrication regime depends on factors such as viscosity, relative surface speed, and load, which together establish a hydrodynamic pressure that sustains the fluid film. In contrast, rolling contact lubrication involves elastohydrodynamic lubrication, where high pressures cause elastic deformation and a thin lubricant film forms, preventing surface damage in rolling elements like bearings and gears.

Principles of Rolling Contact Lubrication

Rolling contact lubrication relies on the formation of a durable lubricating film that separates rolling elements and raceways, minimizing metal-to-metal contact and surface wear. The principle involves maintaining a consistent lubricant film thickness through controlled viscosity and pressure, which supports load distribution while preventing asperity interaction. Fluid film lubrication differs by creating a full hydrodynamic film that completely separates sliding surfaces, whereas rolling contact lubrication adapts to elastic deformation and micro-asperities in the contact zone.

Key Differences: Fluid Film vs Rolling Contact

Fluid film lubrication involves a continuous, pressurized fluid layer separating surfaces, preventing direct metal-to-metal contact and minimizing friction and wear, typically found in hydrodynamic or elastohydrodynamic applications. Rolling contact lubrication occurs between surfaces in rolling motion, such as ball or roller bearings, where a thin lubricant film supports the load, reducing friction but allowing slight deformation at contact points. Key differences include fluid film's reliance on full separation via a robust fluid layer versus rolling contact's partial contact with localized lubrication under high pressure and repeated deformation cycles.

Load-Carrying Capabilities Comparison

Fluid film lubrication provides superior load-carrying capabilities by creating a continuous lubricant layer that completely separates contact surfaces, reducing friction and wear under high-pressure conditions. Rolling contact relies on discrete contact points and often experiences higher localized stresses, limiting its load-carrying capacity compared to fluid film lubrication. Studies show fluid film supports loads up to several thousand Newtons per square millimeter, whereas rolling contact mechanisms typically endure lower maximum pressures before surface fatigue occurs.

Friction and Wear Characteristics

Fluid film lubrication significantly reduces friction by maintaining a continuous lubricant layer between surfaces, preventing direct contact and minimizing wear. Rolling contact involves elements such as balls or rollers that reduce friction compared to sliding contact but still experience localized stress points that can lead to wear over time. Fluid film lubrication typically exhibits lower friction coefficients and enhanced wear resistance compared to rolling contact, which is more susceptible to fatigue and surface degradation under high loads.

Typical Applications of Fluid Film Lubrication

Fluid film lubrication is typically used in high-load and high-speed applications such as journal bearings, hydrodynamic bearings, and large industrial turbines where a continuous oil film separates moving surfaces to minimize friction and wear. This lubrication method is crucial in automotive engines, compressors, and heavy machinery, ensuring smooth operation and extending component lifespan. The fluid film layer adapts to varying loads and speeds, providing reliable performance in critical mechanical systems.

Common Uses of Rolling Contact Lubrication

Rolling contact lubrication is commonly used in applications involving bearings, gears, and rolling mills where reduced friction and wear between rolling elements are critical for performance and longevity. This lubrication method effectively supports heavy loads and high speeds by maintaining a thin lubricant film that minimizes metal-to-metal contact. Industries such as automotive, aerospace, and manufacturing frequently rely on rolling contact lubrication to ensure equipment reliability and operational efficiency.

Performance Influences: Speed, Load, and Environment

Fluid film lubrication maintains a continuous fluid layer between surfaces, ensuring optimal performance at high speeds and moderate loads by minimizing friction and wear. Rolling contact lubrication relies on a thin lubricant film supporting rolling elements, performing efficiently under varying loads but is sensitive to contamination and temperature fluctuations. Environmental factors such as temperature, humidity, and contaminants critically affect lubricant viscosity and film stability, directly impacting the durability and efficiency of both lubrication types.

Choosing the Optimal Lubrication Method

Selecting the optimal lubrication method depends on operating conditions such as load, speed, and surface geometry. Fluid film lubrication excels in high-speed, low-load applications by forming a continuous lubricant layer that prevents metal-to-metal contact. Rolling contact lubrication is more suitable for high-load, slow-speed environments where lubricant film thickness is thinner and boundary lubrication mechanisms dominate.

Fluid film lubrication Infographic

libterm.com

libterm.com