Ultimate tensile strength (UTS) measures the maximum stress a material can withstand while being stretched or pulled before breaking, reflecting its overall mechanical resilience. This property is crucial in engineering and construction, influencing the selection of materials for structures subjected to high stress. Explore the rest of the article to understand how UTS impacts material performance and your project outcomes.

Table of Comparison

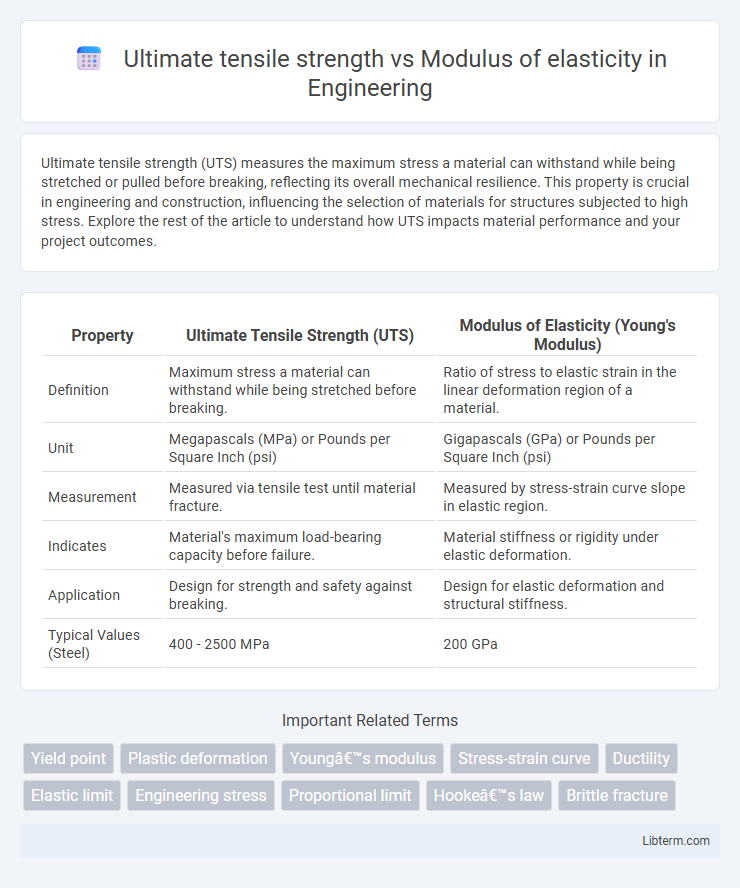

| Property | Ultimate Tensile Strength (UTS) | Modulus of Elasticity (Young's Modulus) |

|---|---|---|

| Definition | Maximum stress a material can withstand while being stretched before breaking. | Ratio of stress to elastic strain in the linear deformation region of a material. |

| Unit | Megapascals (MPa) or Pounds per Square Inch (psi) | Gigapascals (GPa) or Pounds per Square Inch (psi) |

| Measurement | Measured via tensile test until material fracture. | Measured by stress-strain curve slope in elastic region. |

| Indicates | Material's maximum load-bearing capacity before failure. | Material stiffness or rigidity under elastic deformation. |

| Application | Design for strength and safety against breaking. | Design for elastic deformation and structural stiffness. |

| Typical Values (Steel) | 400 - 2500 MPa | 200 GPa |

Introduction to Ultimate Tensile Strength and Modulus of Elasticity

Ultimate tensile strength (UTS) measures the maximum stress a material can withstand while being stretched before breaking, serving as a critical indicator of material toughness. Modulus of elasticity, or Young's modulus, quantifies a material's stiffness by defining the ratio of stress to strain within the elastic deformation region, reflecting its ability to resist shape change. Understanding UTS and modulus of elasticity is essential for selecting materials in engineering applications to ensure structural integrity and performance.

Definition of Ultimate Tensile Strength

Ultimate tensile strength (UTS) refers to the maximum stress a material can withstand while being stretched or pulled before breaking. It is a critical mechanical property measured in units of pressure, such as megapascals (MPa), representing a material's capacity to resist fracture under tension. Modulus of elasticity, also known as Young's modulus, measures a material's stiffness by quantifying the ratio of stress to strain within the elastic deformation region, but unlike UTS, it does not indicate the point of material failure.

Understanding Modulus of Elasticity

Modulus of elasticity, also known as Young's modulus, measures a material's stiffness by quantifying its ability to resist deformation under stress. Unlike ultimate tensile strength, which indicates the maximum stress a material can withstand before failure, modulus of elasticity reflects the initial linear portion of the stress-strain curve, representing elastic behavior. High modulus materials such as steel exhibit minimal elastic deformation, crucial for applications demanding rigidity and dimensional stability.

Key Differences Between Tensile Strength and Modulus of Elasticity

Ultimate tensile strength measures the maximum stress a material can withstand before failure, indicating its breaking point, while modulus of elasticity quantifies a material's stiffness by defining the linear relationship between stress and strain in the elastic deformation region. Tensile strength is expressed in units of pressure such as megapascals (MPa) and is critical for evaluating material durability under load, whereas modulus of elasticity, also in MPa or GPa, is essential for understanding material deformation and rigidity. Unlike tensile strength, which indicates material capacity to resist fracture, modulus of elasticity determines flexibility and elastic limit without causing permanent deformation.

Importance in Material Selection

Ultimate tensile strength defines the maximum stress a material can withstand before failure, making it crucial for applications requiring high load-bearing capacity. Modulus of elasticity measures a material's stiffness, indicating how much it will deform under stress, which is essential for predicting structural behavior and ensuring dimensional stability. Balancing these properties ensures the selection of materials that provide both durability and performance in engineering designs.

Factors Influencing Ultimate Tensile Strength

Ultimate tensile strength (UTS) is significantly influenced by factors such as material composition, microstructure, and the presence of defects or inclusions within the material. Processing conditions including heat treatment, strain rate, and temperature can alter grain size and phase distribution, directly impacting UTS. Modulus of elasticity, while related to stiffness, is less affected by these variables and more dependent on bonding forces and material type.

Factors Affecting Modulus of Elasticity

The modulus of elasticity is influenced by factors such as material composition, temperature, and microstructure, which determine the material's stiffness and ability to deform elastically under stress. Unlike ultimate tensile strength, which measures the maximum stress a material can withstand before failure, the modulus of elasticity quantifies the initial resistance to deformation and is highly sensitive to changes in bonding forces and atomic arrangement. Variations in alloying elements, heat treatment, and grain size significantly affect the modulus, making it a critical parameter for applications requiring precise elastic behavior.

Real-World Applications and Examples

Ultimate tensile strength measures the maximum stress a material can withstand before failure, crucial in selecting materials for load-bearing components like bridge cables and aircraft fuselages. Modulus of elasticity quantifies a material's stiffness, influencing applications that require minimal deformation under stress, such as precision instruments and structural beams. For example, steel has a high ultimate tensile strength for durability in construction, while aluminum's moderate modulus of elasticity suits aerospace parts needing lightweight resilience.

Testing Methods for Each Property

Ultimate tensile strength (UTS) testing involves subjecting a material specimen to uniaxial tensile load using a universal testing machine until fracture to determine the maximum stress it can withstand. Modulus of elasticity testing requires precise strain measurement during elastic deformation, typically using extensometers or strain gauges attached to the specimen in a tension test to calculate the stress-to-strain ratio within the linear elastic region. Both tests follow standardized procedures such as ASTM E8 for metals or ASTM D638 for plastics to ensure accuracy and repeatability.

Summary and Practical Implications

Ultimate tensile strength (UTS) measures the maximum stress a material can withstand before failure, while modulus of elasticity (E) quantifies the material's stiffness by defining the stress-strain relationship within the elastic range. UTS is crucial for assessing material durability under extreme loading, whereas modulus of elasticity determines deformation behavior under normal operational stresses. In practical applications, selecting materials with high UTS ensures safety against fracture, and an appropriate modulus of elasticity guarantees structural rigidity and dimensional stability in engineering designs.

Ultimate tensile strength Infographic

libterm.com

libterm.com