Wood is a versatile and renewable resource widely used in construction, furniture, and crafts due to its strength, durability, and natural beauty. Different types of wood, such as hardwood and softwood, offer unique properties suitable for various applications and environmental conditions. Discover the essential facts and tips to enhance your projects in the rest of this article.

Table of Comparison

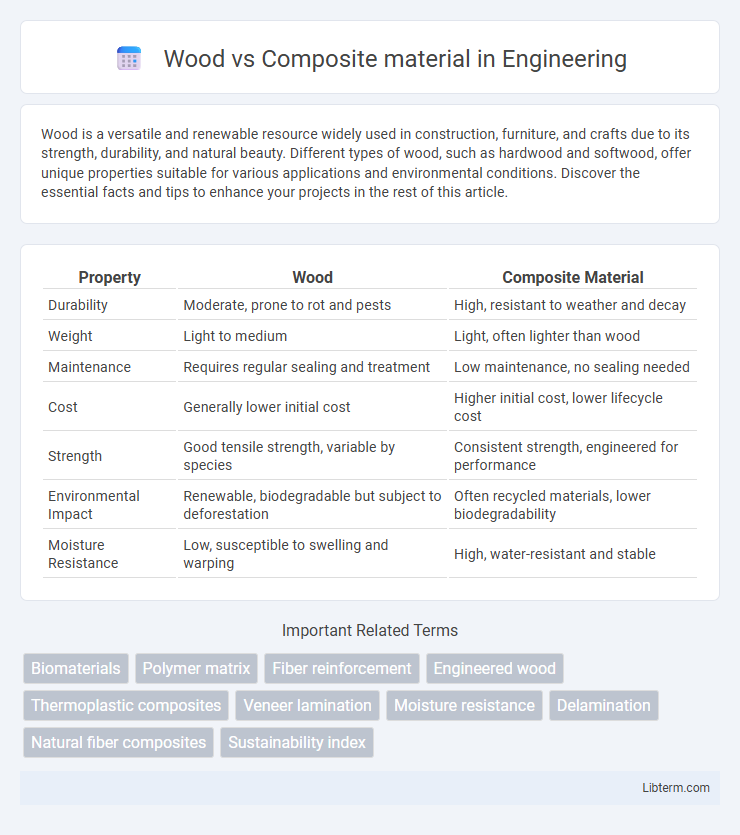

| Property | Wood | Composite Material |

|---|---|---|

| Durability | Moderate, prone to rot and pests | High, resistant to weather and decay |

| Weight | Light to medium | Light, often lighter than wood |

| Maintenance | Requires regular sealing and treatment | Low maintenance, no sealing needed |

| Cost | Generally lower initial cost | Higher initial cost, lower lifecycle cost |

| Strength | Good tensile strength, variable by species | Consistent strength, engineered for performance |

| Environmental Impact | Renewable, biodegradable but subject to deforestation | Often recycled materials, lower biodegradability |

| Moisture Resistance | Low, susceptible to swelling and warping | High, water-resistant and stable |

Introduction to Wood and Composite Materials

Wood, a natural material derived from trees, offers durability, aesthetic appeal, and biodegradability, making it a popular choice for construction and furniture. Composite materials consist of two or more distinct substances, typically combining fibers such as fiberglass or carbon with a resin matrix, resulting in enhanced strength, resistance to moisture, and low maintenance. Understanding the fundamental properties of wood and composite materials is crucial for selecting the appropriate material in applications demanding specific performance criteria and environmental conditions.

Composition and Manufacturing Processes

Wood is a natural, organic material composed primarily of cellulose, hemicellulose, and lignin, harvested from trees and shaped using traditional milling and woodworking techniques. Composite materials combine wood fibers or particles with synthetic polymers like polyethylene or epoxy, created through processes such as extrusion, compression molding, or injection molding. The manufacturing of composites allows for enhanced durability, moisture resistance, and uniformity, contrasting with wood's natural variability and susceptibility to environmental factors.

Durability and Longevity Comparison

Wood offers natural aesthetic appeal but is susceptible to rot, insect damage, and warping, requiring regular maintenance to ensure durability. Composite materials, made from a blend of wood fibers and plastic, provide enhanced resistance to moisture, decay, and pests, significantly extending lifespan with minimal upkeep. Studies show composite decking can last 25 to 30 years, outperforming traditional wood's average durability of 10 to 15 years under similar conditions.

Maintenance Requirements

Wood requires regular maintenance including sealing, staining, and sanding to protect against weathering, rot, and insect damage, typically every 1-3 years depending on climate conditions. Composite materials demand significantly less upkeep, needing only periodic cleaning to prevent mold and surface dirt accumulation, with no sealing or staining necessary. The durability of composite materials reduces long-term maintenance costs and efforts compared to traditional wood.

Environmental Impact and Sustainability

Wood is a renewable resource with a lower carbon footprint due to its ability to sequester carbon dioxide during growth, making it a sustainable choice when sourced from responsibly managed forests. Composite materials, often made from plastics and wood fibers, can be less environmentally friendly because they rely on non-renewable petroleum-based inputs and are more challenging to recycle, leading to increased landfill waste. While composites offer durability and low maintenance, their environmental impact is generally higher than sustainably harvested wood, emphasizing the importance of lifecycle assessment in material selection.

Cost Analysis: Initial and Long-Term

Wood typically has a lower initial cost compared to composite materials, making it attractive for budget-sensitive projects. Over time, composite materials tend to offer better value due to their durability, low maintenance requirements, and resistance to rot, insect damage, and weathering. When considering long-term expenses, composites often result in reduced repair and replacement costs, offsetting their higher upfront price.

Aesthetic Differences and Design Flexibility

Wood offers a natural, warm aesthetic with unique grain patterns that vary in color and texture, providing an organic and timeless look. Composite materials, made from a blend of wood fibers and plastic, offer consistent appearance and are available in a wide range of colors and finishes, allowing for greater design versatility. The design flexibility of composites enables intricate shapes and custom textures that mimic wood while resisting weathering, making them ideal for modern architectural applications.

Performance in Various Climates

Wood offers natural insulation and breathability, making it effective in moderate climates but prone to warping, cracking, or rotting in extreme humidity or temperature fluctuations. Composite materials, engineered with synthetic resins and wood fibers, exhibit superior resistance to moisture, UV rays, and temperature changes, maintaining structural integrity and color over time. Performance in harsh climates favors composite decking for durability, low maintenance, and consistent appearance, while wood requires frequent sealing and treatment to withstand environmental stress.

Safety Considerations

Wood and composite materials differ significantly in safety considerations; wood is susceptible to rot, insect damage, and fire hazards, requiring regular maintenance and treatment to ensure structural integrity. Composite materials, made from a blend of wood fibers and plastic, offer enhanced resistance to moisture, decay, and fire, reducing the risk of structural failure and improving long-term safety. Fire-retardant additives in composites further enhance safety by limiting flame spread and smoke production during exposure to high temperatures.

Choosing the Right Material for Your Project

Selecting the ideal material between wood and composite depends on factors like durability, maintenance, and aesthetic preferences. Wood offers natural beauty and can be more cost-effective but requires regular upkeep to prevent rot and insect damage. Composite materials provide superior resistance to weather and pests with minimal maintenance, making them suitable for long-term outdoor projects.

Wood Infographic

libterm.com

libterm.com