Ductility refers to a material's ability to undergo significant plastic deformation before rupture, making it crucial in manufacturing and structural applications. This property ensures materials like metals can be stretched into wires or bent without breaking, enhancing safety and reliability. Explore the full article to understand how ductility impacts your engineering and construction projects.

Table of Comparison

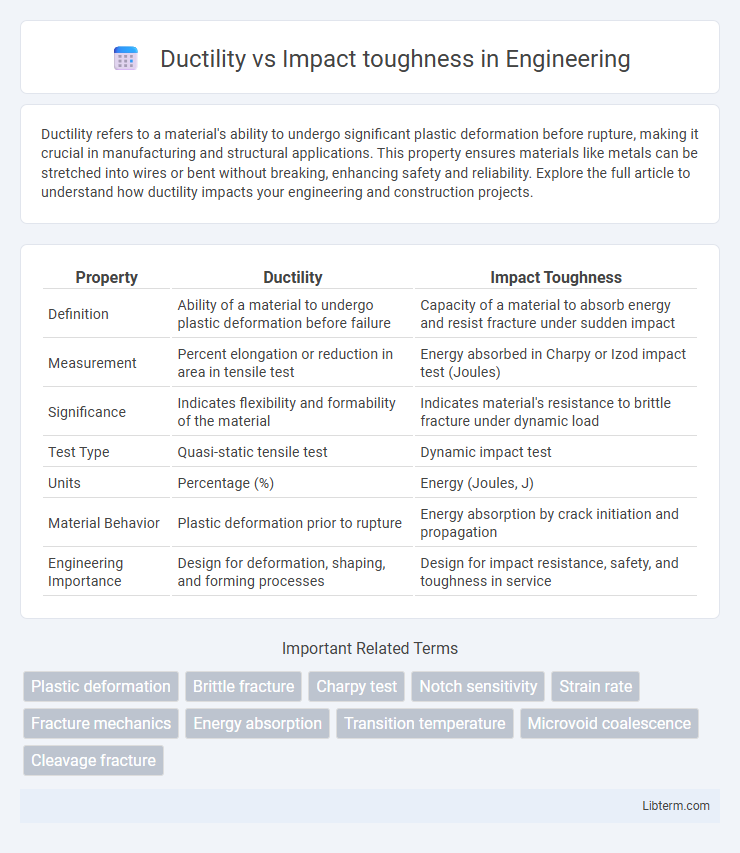

| Property | Ductility | Impact Toughness |

|---|---|---|

| Definition | Ability of a material to undergo plastic deformation before failure | Capacity of a material to absorb energy and resist fracture under sudden impact |

| Measurement | Percent elongation or reduction in area in tensile test | Energy absorbed in Charpy or Izod impact test (Joules) |

| Significance | Indicates flexibility and formability of the material | Indicates material's resistance to brittle fracture under dynamic load |

| Test Type | Quasi-static tensile test | Dynamic impact test |

| Units | Percentage (%) | Energy (Joules, J) |

| Material Behavior | Plastic deformation prior to rupture | Energy absorption by crack initiation and propagation |

| Engineering Importance | Design for deformation, shaping, and forming processes | Design for impact resistance, safety, and toughness in service |

Understanding Ductility: Definition and Importance

Ductility refers to a material's ability to undergo significant plastic deformation before fracture, which is crucial for applications requiring flexibility and shape alteration without failure. It is typically measured by elongation or reduction in area during tensile testing, providing insight into a material's capacity to absorb energy and deform under stress. Understanding ductility helps engineers select materials that can withstand mechanical stresses while maintaining structural integrity, differentiating it from impact toughness, which specifically assesses resistance to sudden forces or shocks.

What is Impact Toughness? Key Concepts Explained

Impact toughness measures a material's ability to absorb energy and resist fracture under sudden, high-strain-rate loading conditions, often assessed using tests like the Charpy or Izod impact tests. Unlike ductility, which quantifies the extent to which a material can deform plastically before failure, impact toughness evaluates both strength and energy absorption capacity during a rapid impact event. Key factors influencing impact toughness include temperature, microstructure, and strain rate sensitivity, making it crucial for applications requiring resistance to dynamic or shock loading.

Fundamental Differences: Ductility vs Impact Toughness

Ductility measures a material's ability to undergo plastic deformation under tensile stress without fracturing, reflecting how much it can stretch or elongate. Impact toughness quantifies a material's capacity to absorb energy during a sudden impact or shock load, highlighting resistance to brittle fracture. The fundamental difference lies in ductility assessing deformation behavior under slow or steady loading, while impact toughness evaluates energy absorption under rapid, high-strain-rate conditions.

Measuring Ductility: Common Methods and Standards

Measuring ductility commonly involves tensile testing methods such as the ASTM E8/E8M standard, which evaluates elongation and reduction of area to quantify material deformation before fracture. Charpy impact tests, defined under ASTM E23, primarily assess impact toughness but can indirectly provide insights into ductility by observing energy absorption during fracture. Accurate ductility measurement ensures material performance reliability in applications subjected to plastic deformation and impact loading.

Testing Impact Toughness: Charpy and Izod Methods

Impact toughness testing evaluates a material's ability to absorb energy during fracture under high strain rates, with Charpy and Izod methods being the most common standardized tests. The Charpy test measures the energy absorbed by a notched specimen struck by a pendulum, emphasizing material resistance to impact in a fixed position, while the Izod test evaluates the absorbed energy with the specimen clamped vertically, highlighting differences in stress distribution. Both methods provide critical data for assessing fracture behavior and material selection in applications requiring balanced ductility and impact toughness.

Material Structure and Its Effect on Ductility

Ductility is heavily influenced by the material's microstructure, where a fine-grained structure typically enhances ductile behavior by allowing more slip systems for dislocation movement. In contrast, impact toughness depends on the material's ability to absorb energy during fracture, which can be affected by the presence of microstructural defects or phase boundaries that initiate cracks. Materials with a balanced combination of grain size, phase distribution, and fewer inclusions tend to exhibit both high ductility and impact toughness, as the microstructural attributes promote plastic deformation before brittle failure.

Factors Influencing Impact Toughness in Materials

Impact toughness in materials is strongly influenced by factors such as microstructure, temperature, and strain rate. Fine-grained microstructures and low temperatures typically reduce impact toughness, while higher strain rates can increase the material's resistance to sudden shocks. Alloy composition and heat treatment processes also play critical roles in optimizing impact toughness by improving energy absorption during fracture.

Real-World Applications: When to Prioritize Ductility vs Impact Toughness

Ductility is prioritized in applications requiring extensive deformation without fracture, such as metal forming, automotive body panels, and structural components in earthquake-prone regions where materials must absorb strain and prevent catastrophic failure. Impact toughness becomes critical in scenarios involving sudden or dynamic loads, such as aerospace components, protective gear, and pipelines subjected to rapid pressure surges, where resistance to crack propagation under high strain rates is essential. Selecting between ductility and impact toughness depends on the operational environment, load conditions, and the necessity for energy absorption versus shape adaptation.

Case Studies: Failures Linked to Poor Ductility or Impact Toughness

Case studies reveal that failures in materials with poor ductility often manifest as brittle fractures under tensile stress, exemplified by the catastrophic collapse of the Silver Bridge in 1967 due to stress corrosion cracking and insufficient ductility of the eye-bar material. Impact toughness deficiencies have led to fractures in low-temperature applications, such as the Liberty ships during World War II, where brittle rupture occurred from inadequate impact toughness in welds exposed to cold seawater. These failures underscore the critical need to optimize both ductility and impact toughness for structural components subjected to dynamic and harsh environments.

Choosing the Right Property for Engineering Design Decisions

Ductility measures a material's ability to deform plastically before fracturing, which is crucial for applications requiring flexibility and shape changes under stress. Impact toughness quantifies a material's capacity to absorb energy during sudden impacts or shock loading, essential for components exposed to dynamic forces. Selecting between ductility and impact toughness depends on specific engineering demands, where ductility favors deformation resilience and impact toughness ensures resistance to brittle failure in abrupt loading conditions.

Ductility Infographic

libterm.com

libterm.com