Continuous cutting offers a streamlined approach to manufacturing, enhancing efficiency by minimizing downtime and maintaining consistent precision. This technique is essential for industries requiring high-volume production with tight tolerances to reduce waste and improve product quality. Explore the rest of the article to discover how continuous cutting can optimize your manufacturing processes and boost productivity.

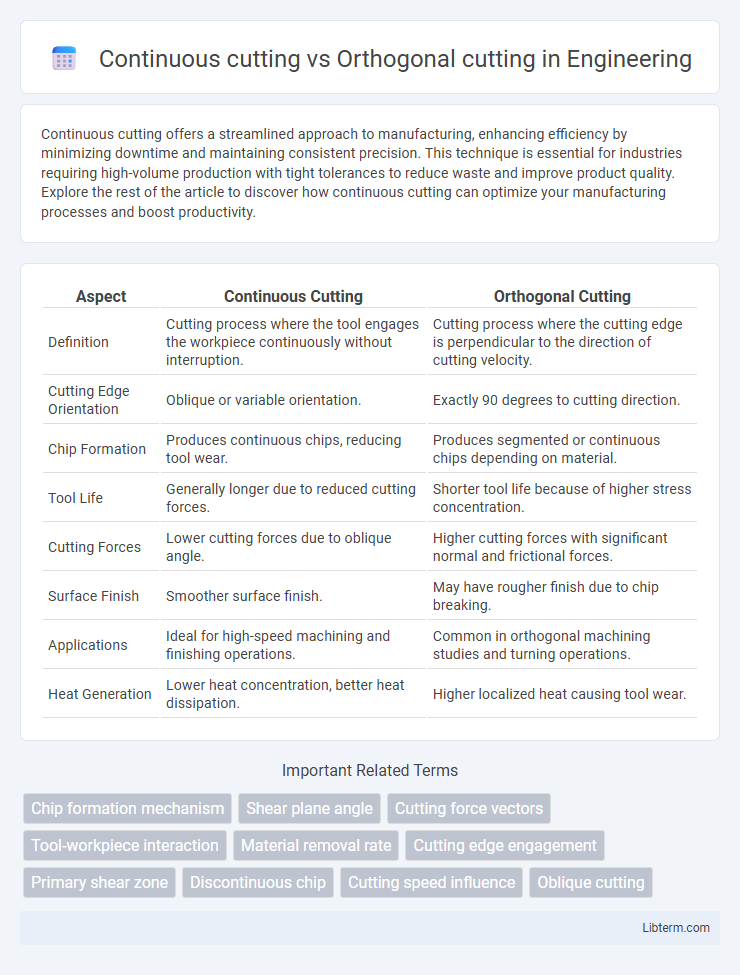

Table of Comparison

| Aspect | Continuous Cutting | Orthogonal Cutting |

|---|---|---|

| Definition | Cutting process where the tool engages the workpiece continuously without interruption. | Cutting process where the cutting edge is perpendicular to the direction of cutting velocity. |

| Cutting Edge Orientation | Oblique or variable orientation. | Exactly 90 degrees to cutting direction. |

| Chip Formation | Produces continuous chips, reducing tool wear. | Produces segmented or continuous chips depending on material. |

| Tool Life | Generally longer due to reduced cutting forces. | Shorter tool life because of higher stress concentration. |

| Cutting Forces | Lower cutting forces due to oblique angle. | Higher cutting forces with significant normal and frictional forces. |

| Surface Finish | Smoother surface finish. | May have rougher finish due to chip breaking. |

| Applications | Ideal for high-speed machining and finishing operations. | Common in orthogonal machining studies and turning operations. |

| Heat Generation | Lower heat concentration, better heat dissipation. | Higher localized heat causing tool wear. |

Introduction to Cutting Processes

Continuous cutting involves a constant chip formation process where the tool removes material smoothly, resulting in a uniform surface finish and consistent cutting forces. Orthogonal cutting, characterized by the cutting edge being perpendicular to the direction of tool travel, simplifies analysis by separating cutting and thrust forces, making it ideal for studying fundamental metal removal mechanisms. Both processes are essential in manufacturing for understanding chip formation, tool wear, and optimizing cutting conditions to improve efficiency and product quality.

Defining Continuous Cutting

Continuous cutting involves a machining process where the cutting tool maintains unbroken engagement with the workpiece, resulting in a smooth and consistent chip formation. This method contrasts with orthogonal cutting, where the cutting edge is perpendicular to the direction of the tool's movement, often producing segmented chips. Continuous cutting reduces vibrations and improves surface finish due to steady contact between tool and material.

Understanding Orthogonal Cutting

Orthogonal cutting involves a single cutting edge moving perpendicular to the workpiece surface, creating a clearly defined shear plane where material deformation occurs. This process simplifies analysis by focusing on two-dimensional forces, making it essential for understanding chip formation, cutting forces, and tool wear. Unlike continuous cutting, orthogonal cutting provides precise control over cutting parameters and efficient material removal in machining operations.

Key Differences between Continuous and Orthogonal Cutting

Continuous cutting involves a smooth, uninterrupted removal of material, typically achieved with sharp cutting tools producing a continuous chip, while orthogonal cutting features a straight, perpendicular cutting edge resulting in segmented chip formation. The primary distinction lies in chip type--continuous chips indicate steady material flow and lower cutting forces, whereas orthogonal cutting chips are discontinuous, causing higher stress on the workpiece. Tool geometry and cutting mechanics also differ significantly, influencing surface finish quality and tool wear rates in manufacturing processes.

Advantages of Continuous Cutting

Continuous cutting offers superior surface finish quality and reduced tool wear compared to orthogonal cutting due to its steady shear action along the cutting edge. The process generates less vibration and heat, enabling higher cutting speeds and improved dimensional accuracy in machining operations. Continuous cutting is particularly advantageous for machining ductile materials, where it minimizes chip segmentation and enhances overall process stability.

Benefits of Orthogonal Cutting

Orthogonal cutting offers precise control over chip formation and cutting forces, resulting in improved surface finish and dimensional accuracy. This method reduces tool wear by maintaining consistent tool-workpiece contact angles, enhancing tool life and productivity. It also facilitates easier analysis of cutting mechanics, enabling optimized process parameters and efficient material removal.

Applications in Modern Manufacturing

Continuous cutting excels in high-speed machining of ductile metals, enhancing surface finish and tool life in automotive and aerospace component production. Orthogonal cutting is preferred for precise material removal in machining operations like turning and grooving, commonly used in manufacturing precision parts for medical devices and electronics. Both techniques optimize manufacturing efficiency by aligning cutting methods with specific material properties and production requirements.

Tool Wear and Chip Formation

Continuous cutting produces uniform, ribbon-like chips resulting in steady tool wear due to consistent cutting forces and temperatures. Orthogonal cutting generates segmented or discontinuous chips, leading to fluctuating stresses that accelerate tool wear through mechanical and thermal fatigue. Tool wear rates differ significantly as continuous cutting favors wear mechanisms like abrasion, while orthogonal cutting enhances chipping and crater wear from intermittent impact loads.

Surface Finish and Quality Comparison

Continuous cutting typically generates smoother surface finishes due to steady tool engagement, minimizing vibrations and tool marks on the workpiece. Orthogonal cutting, characterized by a perpendicular cutting edge, often produces better dimensional accuracy and consistent chip formation, contributing to higher surface quality in precision machining. Surface finish quality in continuous cutting excels in applications requiring fine aesthetics, while orthogonal cutting ensures superior control over material removal and surface integrity in engineering-critical parts.

Choosing the Right Cutting Method

Choosing the right cutting method depends on the material properties and desired surface finish, where continuous cutting excels with ductile materials by producing smooth, continuous chips that reduce tool wear. Orthogonal cutting suits brittle materials, emphasizing precision and controlled chip formation in a single shear plane for enhanced dimensional accuracy. Evaluating cutting forces, chip morphology, and tool life ensures optimal method selection for improved machining efficiency and product quality.

Continuous cutting Infographic

libterm.com

libterm.com