Composite materials combine two or more distinct substances to create a product with superior properties such as increased strength, durability, and lightweight characteristics. Commonly used in aerospace, automotive, and construction industries, composites offer enhanced performance while reducing material costs and environmental impact. Explore the full article to discover how composite materials can revolutionize your next project.

Table of Comparison

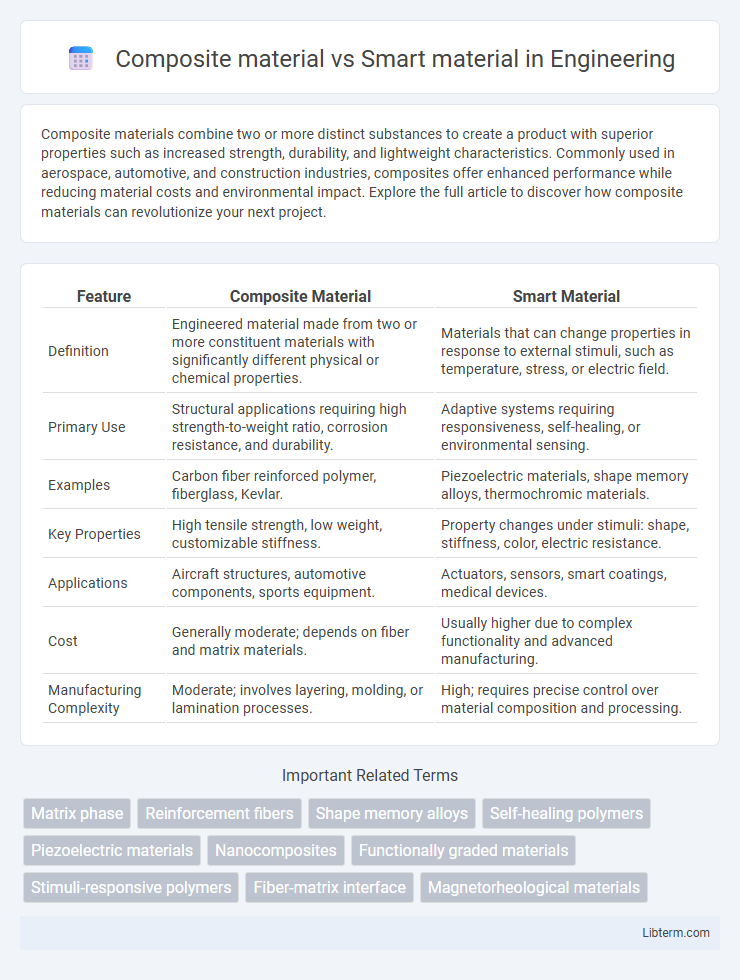

| Feature | Composite Material | Smart Material |

|---|---|---|

| Definition | Engineered material made from two or more constituent materials with significantly different physical or chemical properties. | Materials that can change properties in response to external stimuli, such as temperature, stress, or electric field. |

| Primary Use | Structural applications requiring high strength-to-weight ratio, corrosion resistance, and durability. | Adaptive systems requiring responsiveness, self-healing, or environmental sensing. |

| Examples | Carbon fiber reinforced polymer, fiberglass, Kevlar. | Piezoelectric materials, shape memory alloys, thermochromic materials. |

| Key Properties | High tensile strength, low weight, customizable stiffness. | Property changes under stimuli: shape, stiffness, color, electric resistance. |

| Applications | Aircraft structures, automotive components, sports equipment. | Actuators, sensors, smart coatings, medical devices. |

| Cost | Generally moderate; depends on fiber and matrix materials. | Usually higher due to complex functionality and advanced manufacturing. |

| Manufacturing Complexity | Moderate; involves layering, molding, or lamination processes. | High; requires precise control over material composition and processing. |

Introduction to Composite and Smart Materials

Composite materials consist of two or more distinct constituents combined to achieve superior mechanical properties, such as increased strength, stiffness, and durability, compared to individual components. Smart materials possess the ability to respond adaptively to external stimuli like temperature, stress, or electric fields, enabling applications in sensing, actuation, and self-healing. Both materials enhance performance in advanced engineering fields, with composites primarily optimizing structural integrity and smart materials focusing on functional adaptability.

Definition and Key Characteristics of Composite Materials

Composite materials consist of two or more distinct constituents combined to achieve superior mechanical properties, such as enhanced strength, lightweight, and corrosion resistance. These materials typically include a matrix, like polymer, metal, or ceramic, reinforced by fibers or particles to improve performance and durability under various stress conditions. Unlike smart materials, composites lack inherent responsiveness to environmental stimuli, focusing instead on structural integrity and tailored physical attributes.

Definition and Key Characteristics of Smart Materials

Smart materials are substances that can respond dynamically to environmental stimuli such as temperature, pressure, moisture, or electric and magnetic fields by altering their properties in a controlled manner. Unlike composite materials, which combine two or more distinct materials to enhance mechanical strength and durability, smart materials exhibit adaptability, self-healing, or shape memory effects. Key characteristics of smart materials include their ability to sense changes, process inputs, and actuate responses, making them integral to advanced engineering and responsive systems.

Composition and Structure Comparison

Composite materials consist of two or more distinct constituents, such as fibers embedded in a matrix, designed to optimize mechanical properties like strength and stiffness through their heterogeneous structure. Smart materials contain embedded sensors, actuators, or responsive elements allowing them to adapt to environmental changes by altering their physical properties dynamically. While composites focus on static reinforcement at a macro or micro scale, smart materials integrate functional components at the molecular or structural level for active responsiveness.

Functional Properties and Performance Differences

Composite materials consist of two or more constituent materials with distinct physical or chemical properties, designed for enhanced mechanical strength, durability, and lightweight performance. Smart materials exhibit adaptive functional properties such as shape memory, piezoelectricity, or self-healing abilities, enabling real-time response to environmental stimuli like temperature, stress, or electric fields. The performance difference lies in composites primarily providing static structural improvements, while smart materials offer dynamic functionality that alters their behavior based on external conditions, making them ideal for advanced sensing and actuation applications.

Typical Applications in Industry

Composite materials are widely utilized in aerospace, automotive, and construction industries for their high strength-to-weight ratio and corrosion resistance, enabling lightweight structural components and durable infrastructure. Smart materials are primarily applied in robotics, aerospace, and biomedical devices, where their ability to respond to environmental stimuli, such as temperature, stress, or electric fields, allows for adaptive sensors, actuators, and self-healing systems. The integration of smart materials in industrial applications enhances functionality and efficiency, while composites provide fundamental mechanical support and durability.

Advantages and Limitations of Composite Materials

Composite materials offer high strength-to-weight ratios, corrosion resistance, and tailored mechanical properties, making them ideal for aerospace, automotive, and construction applications. Limitations include complex manufacturing processes, higher costs, and challenges in repairability compared to traditional materials. Despite these drawbacks, composites provide enhanced performance and design flexibility that are unmatched by many conventional materials.

Advantages and Limitations of Smart Materials

Smart materials offer significant advantages such as their ability to respond dynamically to environmental stimuli like temperature, pressure, and electric fields, enabling adaptive performance in aerospace, biomedical, and automotive industries. However, limitations include higher manufacturing costs, complex integration requirements, and potential durability issues under prolonged exposure to harsh conditions. Compared to composite materials, smart materials excel in functionality but often face challenges in large-scale production and long-term reliability.

Future Trends in Material Science

Future trends in material science emphasize the integration of composite materials with smart functionalities to create adaptive structures capable of self-healing, shape memory, and environmental responsiveness. Advanced composites combining carbon fiber reinforcements with embedded sensors and actuators enable real-time monitoring and performance optimization in aerospace and automotive industries. Innovations in nanotechnology and artificial intelligence-driven design accelerate the development of multifunctional smart composites, driving sustainable and high-performance solutions for next-generation applications.

Choosing the Right Material: Composite vs Smart Material

Choosing the right material depends on application demands: composite materials, known for their high strength-to-weight ratio and excellent durability, excel in structural applications such as aerospace and automotive industries. Smart materials offer adaptive properties like shape memory, self-healing, and responsiveness to environmental stimuli, making them ideal for sensors, actuators, and biomedical devices. Evaluating factors such as mechanical performance, environmental interaction, and functionality requirements guides optimal selection between composite and smart materials.

Composite material Infographic

libterm.com

libterm.com