The diesel cycle is a thermodynamic process that powers diesel engines through compression ignition, where air is compressed to high pressure and temperature before fuel injection. This cycle offers higher efficiency and better fuel economy compared to gasoline engines due to its lean burn characteristics and higher compression ratios. Explore the article to understand how the diesel cycle maximizes engine performance and fuel efficiency.

Table of Comparison

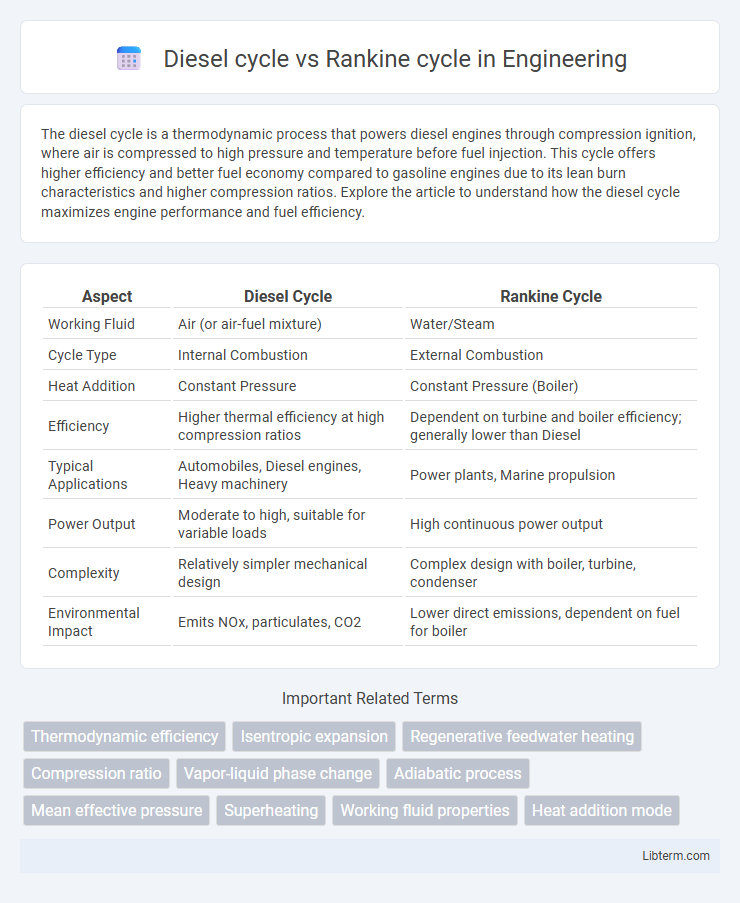

| Aspect | Diesel Cycle | Rankine Cycle |

|---|---|---|

| Working Fluid | Air (or air-fuel mixture) | Water/Steam |

| Cycle Type | Internal Combustion | External Combustion |

| Heat Addition | Constant Pressure | Constant Pressure (Boiler) |

| Efficiency | Higher thermal efficiency at high compression ratios | Dependent on turbine and boiler efficiency; generally lower than Diesel |

| Typical Applications | Automobiles, Diesel engines, Heavy machinery | Power plants, Marine propulsion |

| Power Output | Moderate to high, suitable for variable loads | High continuous power output |

| Complexity | Relatively simpler mechanical design | Complex design with boiler, turbine, condenser |

| Environmental Impact | Emits NOx, particulates, CO2 | Lower direct emissions, dependent on fuel for boiler |

Introduction to Diesel and Rankine Cycles

The Diesel cycle, commonly used in compression-ignition engines, operates through high compression ratios enabling fuel auto-ignition, enhancing thermal efficiency. The Rankine cycle, fundamental to steam power plants, converts heat into mechanical work via phase changes of water between liquid and vapor states. Both cycles are pivotal in thermodynamic systems, with Diesel optimizing fuel combustion and Rankine maximizing steam energy utilization.

Overview of Diesel Cycle

The Diesel cycle is a thermodynamic cycle that describes the functioning of a compression-ignition internal combustion engine, primarily used in diesel engines. It operates through four distinct strokes: intake, compression, power, and exhaust, with fuel ignition occurring due to high compression temperatures rather than spark. Compared to the Rankine cycle, which is commonly employed in steam power plants utilizing phase change of water, the Diesel cycle is characterized by air-standard assumptions and a focus on fuel efficiency and higher compression ratios.

Overview of Rankine Cycle

The Rankine cycle operates as a thermodynamic process commonly used in steam power plants for electricity generation, converting heat into mechanical work through phase changes of water. It involves four key stages: water heating by a boiler, steam expansion in a turbine, condensation in a condenser, and pumping of condensed water back to the boiler. This cycle is highly efficient for low to medium temperature heat sources and is distinguished by its closed-loop system using liquid-vapor phase change to optimize energy conversion.

Working Principles Compared

The Diesel cycle operates on the principle of compression ignition, where air is compressed to a high temperature before fuel injection causes spontaneous combustion, leading to power generation in internal combustion engines. The Rankine cycle, primarily used in steam power plants, relies on phase change of a working fluid, typically water, undergoing evaporation in a boiler, expansion through a turbine, condensation, and pumping to complete the cycle. Efficiency differences arise from the Diesel cycle's direct combustion and high compression ratios, while the Rankine cycle depends on heat transfer and fluid phase transitions for energy conversion.

Key Components in Each Cycle

The Diesel cycle primarily consists of a piston-cylinder arrangement, fuel injector, air intake and exhaust valves, and a crankshaft to convert combustion into mechanical work. The Rankine cycle features a boiler, steam turbine, condenser, and feedwater pump to convert heat into mechanical energy through phase change of a working fluid. Both cycles optimize energy conversion but differ in components and operational mechanisms tailored to internal combustion and steam power, respectively.

Thermodynamic Processes Involved

The Diesel cycle operates through a sequence of isentropic compression, constant-pressure combustion, isentropic expansion, and constant-volume exhaust processes, optimizing fuel efficiency in internal combustion engines. In contrast, the Rankine cycle employs isentropic compression and expansion along with constant-pressure heat addition and rejection, commonly used in steam power plants for converting thermal energy into mechanical work. The key thermodynamic distinction lies in the Diesel cycle's combustion at constant pressure versus the Rankine cycle's phase change heat transfer, impacting cycle efficiency and application suitability.

Efficiency Comparison: Diesel vs Rankine

The Diesel cycle typically achieves higher thermal efficiency due to its higher compression ratio and direct fuel injection, making it more efficient for internal combustion engines. In contrast, the Rankine cycle, used in steam power plants, operates at lower temperatures and pressures, resulting in relatively lower efficiency but greater reliability and fuel flexibility. Efficiency improvements in the Diesel cycle often exceed 40%, while modern Rankine cycles generally reach efficiencies between 35% and 40%.

Common Applications and Uses

The Diesel cycle is primarily used in internal combustion engines for heavy-duty vehicles, construction machinery, and power generation due to its high thermal efficiency and ability to operate on lower-quality fuels. The Rankine cycle is extensively applied in steam power plants, including coal, nuclear, and geothermal power stations, converting heat into mechanical work for electricity production. Diesel engines dominate mobile and industrial applications, while the Rankine cycle is central to large-scale stationary power generation.

Environmental Impact and Emissions

The Diesel cycle typically produces higher nitrogen oxides (NOx) emissions due to its high combustion temperatures, impacting air quality more severely than the Rankine cycle. The Rankine cycle, often employed in steam power plants, tends to have lower direct emissions but depends heavily on the fuel type and combustion technology used, influencing its overall carbon footprint. Advances in emission control technologies and renewable integrations are crucial for reducing the environmental impact of both cycles.

Conclusion: Choosing the Right Cycle

Choosing the right cycle between Diesel and Rankine depends on the specific application requirements, efficiency goals, and fuel availability. The Diesel cycle excels in high-efficiency internal combustion engine applications with direct fuel use, making it ideal for transportation and power generation where compact size and rapid response are critical. The Rankine cycle is better suited for large-scale power plants utilizing steam turbines, offering reliable operation with diverse fuel sources like coal, nuclear, or biomass for sustained energy generation.

Diesel cycle Infographic

libterm.com

libterm.com