Plain bearings provide low-friction movement between two surfaces without the use of rolling elements, making them ideal for applications with high loads and low speeds. These bearings require minimal maintenance and can handle misalignment and shock loads better than ball bearings. Discover how plain bearing technology can enhance your machinery's performance by reading the full article.

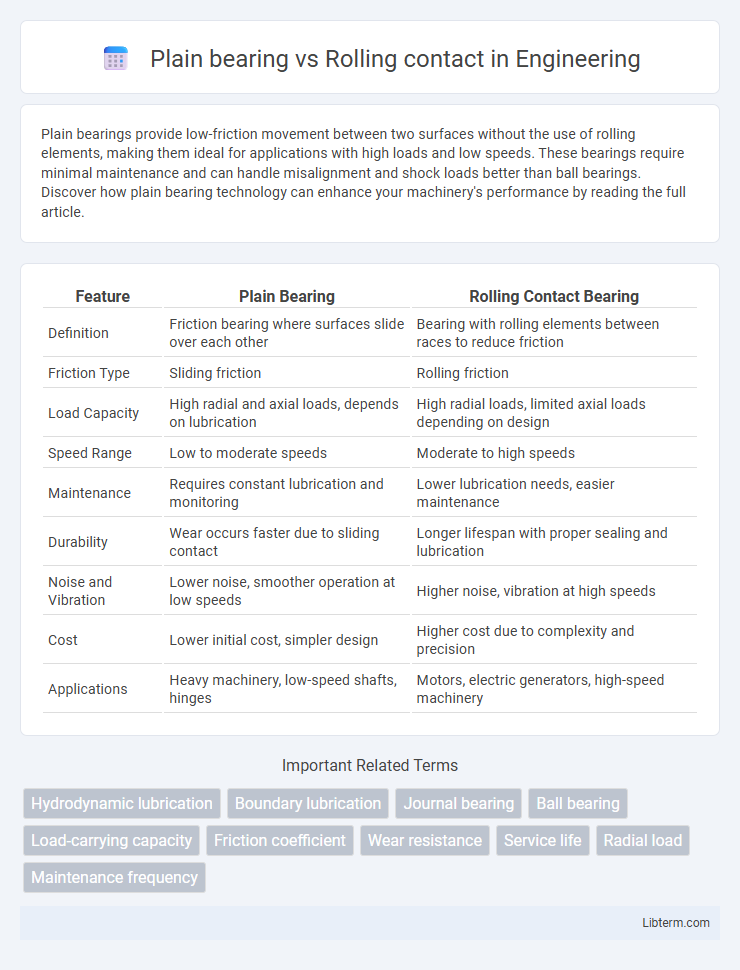

Table of Comparison

| Feature | Plain Bearing | Rolling Contact Bearing |

|---|---|---|

| Definition | Friction bearing where surfaces slide over each other | Bearing with rolling elements between races to reduce friction |

| Friction Type | Sliding friction | Rolling friction |

| Load Capacity | High radial and axial loads, depends on lubrication | High radial loads, limited axial loads depending on design |

| Speed Range | Low to moderate speeds | Moderate to high speeds |

| Maintenance | Requires constant lubrication and monitoring | Lower lubrication needs, easier maintenance |

| Durability | Wear occurs faster due to sliding contact | Longer lifespan with proper sealing and lubrication |

| Noise and Vibration | Lower noise, smoother operation at low speeds | Higher noise, vibration at high speeds |

| Cost | Lower initial cost, simpler design | Higher cost due to complexity and precision |

| Applications | Heavy machinery, low-speed shafts, hinges | Motors, electric generators, high-speed machinery |

Introduction to Plain Bearings and Rolling Contact Bearings

Plain bearings, also known as slide or sleeve bearings, provide frictional support between two surfaces through sliding motion, typically using materials like bronze, graphite, or PTFE for smooth operation and load distribution. Rolling contact bearings, including ball and roller bearings, utilize rolling elements to minimize friction and handle radial and axial loads efficiently, making them suitable for high-speed and precision applications. Understanding the fundamental design differences, load capacities, and lubrication requirements is essential for selecting the appropriate bearing type in mechanical systems.

Basic Construction and Operating Principles

Plain bearings consist of a simple cylindrical surface that slides against a shaft, relying on a lubricant film to reduce friction during relative motion. Rolling contact bearings incorporate rolling elements such as balls or rollers between the inner and outer rings, converting sliding friction into rolling friction for smoother operation and higher load capacity. The fundamental operating principle of plain bearings depends on hydrodynamic lubrication, while rolling bearings utilize the rolling motion of elements to minimize resistance and wear.

Key Differences Between Plain and Rolling Contact Bearings

Plain bearings operate through sliding motion with a thin lubricating film between surfaces, resulting in lower speed capabilities but high load capacity and simplicity in design. Rolling contact bearings use rolling elements like balls or rollers to minimize friction, offering higher speed performance and greater precision but often at increased complexity and cost. Key differences include friction type, load classification, maintenance requirements, and suitable applications, with plain bearings favored for heavy loads and rolling bearings preferred for high-speed, precision machinery.

Load Capacity and Performance Efficiency

Plain bearings typically offer higher load capacity due to their larger contact surface area distributing forces evenly, which reduces stress concentrations and improves durability under heavy loads. Rolling contact bearings provide superior performance efficiency by minimizing friction through rolling elements, resulting in lower energy consumption and smoother motion, especially at high speeds. Load capacity for rolling bearings is limited by point contact stress, while plain bearings excel in shock load applications and harsh environments where contamination or misalignment are factors.

Friction and Wear Characteristics

Plain bearings exhibit higher friction due to the sliding contact between surfaces, leading to increased wear in applications with inadequate lubrication. Rolling contact bearings minimize friction by employing rolling elements, which significantly reduce wear and extend service life under dynamic loads. Materials with low friction coefficients and proper lubrication are essential in plain bearings to mitigate wear, whereas rolling contact bearings rely more on precise manufacturing to ensure minimal friction and longevity.

Maintenance and Lubrication Requirements

Plain bearings require regular lubrication using oils or grease to reduce friction and prevent wear, as inadequate lubrication leads to increased maintenance and potential failure. Rolling contact bearings typically need less frequent lubrication due to built-in rolling elements but still demand periodic inspection and relubrication to avoid contamination and ensure longevity. Both bearing types benefit from clean operating environments and proper lubrication schedules to optimize performance and reduce downtime.

Common Applications in Industry

Plain bearings are widely used in heavy machinery, automotive engines, and hydraulic systems due to their simplicity, load capacity, and ability to operate in contaminated environments. Rolling contact bearings dominate applications requiring high-speed rotation and precision, such as electric motors, aerospace components, and machine tools. Industries like manufacturing, transportation, and energy rely on selecting between plain and rolling bearings based on load type, speed, and maintenance demands.

Advantages and Disadvantages Comparison

Plain bearings offer simplicity, low cost, and excellent performance in high-load, low-speed applications due to their minimal moving parts and reduced friction through lubrication. Rolling contact bearings provide higher speed capability, reduced friction, and better precision, making them ideal for applications requiring rapid rotational movement and accurate positioning, but they are generally more complex and expensive. Plain bearings may suffer from wear and heat buildup under high-speed conditions, whereas rolling contact bearings can be sensitive to shock loads and require regular maintenance for optimal performance.

Cost Analysis and Longevity

Plain bearings generally offer lower initial costs compared to rolling contact bearings due to simpler design and fewer components, making them ideal for budget-sensitive applications. Rolling contact bearings typically provide longer service life and reduced maintenance needs because of their ability to minimize friction and wear under high-load conditions. Cost analysis should weigh upfront expenses against lifespan and replacement frequency, with plain bearings favored for low-speed or intermittent use and rolling contact bearings preferred in high-speed, high-precision environments.

Selecting the Right Bearing for Your Application

Selecting the right bearing for your application depends on factors such as load type, speed, and environmental conditions. Plain bearings are ideal for applications requiring high load capacity, low speed, and minimal maintenance, as they provide a simple and cost-effective solution with excellent shock absorption. Rolling contact bearings excel in high-speed and precision applications due to their low friction, ability to handle radial and axial loads, and longer service life under consistent operating conditions.

Plain bearing Infographic

libterm.com

libterm.com