Force fit refers to the process of rigidly inserting or fitting components together despite dimensional mismatches or tight tolerances, often requiring applied pressure or mechanical force. This technique ensures secure assembly and reliable mechanical connections in engineering and manufacturing applications. Discover how mastering force fit can improve your project's structural integrity and efficiency by reading the full article.

Table of Comparison

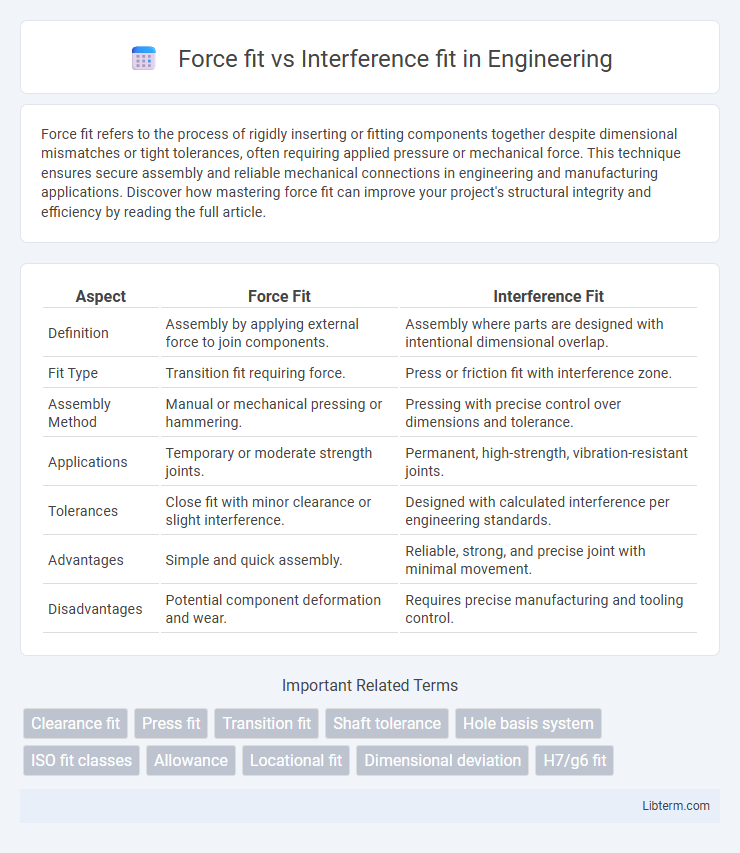

| Aspect | Force Fit | Interference Fit |

|---|---|---|

| Definition | Assembly by applying external force to join components. | Assembly where parts are designed with intentional dimensional overlap. |

| Fit Type | Transition fit requiring force. | Press or friction fit with interference zone. |

| Assembly Method | Manual or mechanical pressing or hammering. | Pressing with precise control over dimensions and tolerance. |

| Applications | Temporary or moderate strength joints. | Permanent, high-strength, vibration-resistant joints. |

| Tolerances | Close fit with minor clearance or slight interference. | Designed with calculated interference per engineering standards. |

| Advantages | Simple and quick assembly. | Reliable, strong, and precise joint with minimal movement. |

| Disadvantages | Potential component deformation and wear. | Requires precise manufacturing and tooling control. |

Understanding Fit Types in Engineering

Force fit and interference fit are engineering methods used to join two components with a tight, secure connection by creating intentional dimensional overlap. Force fit typically involves pressing or hammering a slightly larger shaft into a smaller hole, relying on frictional force to maintain joint integrity. Interference fit refers to a precise manufacturing tolerance where the shaft diameter exceeds the hole diameter by a controlled amount, ensuring stress and deformation generate a robust, vibration-resistant assembly.

What is a Force Fit?

A force fit refers to the assembly method where two parts are joined by applying pressure, creating a tight, secure connection without additional fasteners. This type of fit relies on precise machining tolerances to ensure the parts deform slightly and hold together due to friction and mechanical stress. Force fits are commonly used in applications like press-fit bearings or shafts, where maintaining a firm bond under operational loads is critical.

What is an Interference Fit?

An interference fit, also known as a press fit, is a fastening method where two mating parts are designed with slightly overlapping dimensions, creating a tight, secure connection through friction. This fit relies on precise engineering tolerances to ensure that the inner component is slightly larger than the hole, causing deformation and resistance upon assembly. The resulting mechanical bond provides high load capacity and prevents relative motion without the need for additional adhesives or fasteners.

Key Differences: Force Fit vs Interference Fit

Force fit and interference fit both describe methods of joining components by creating a tight fit, but they differ in the degree and application of the fit. Force fit typically involves pressing parts together with an external force, resulting in a temporary or semi-permanent joint without material deformation. Interference fit, also known as a press or friction fit, involves a purposeful slight dimensional oversize of one part causing elastic deformation when assembled, producing a stronger and more permanent joint due to the material interference.

Applications of Force Fits

Force fits are widely used in mechanical assemblies where components must be securely joined without relative movement, such as in mounting gears on shafts or attaching bearings to housings. This method ensures high load transfer and precise alignment, making it ideal for heavy-duty machinery and automotive applications. The interference created by the force fit enhances stability and durability under dynamic and static loads.

Applications of Interference Fits

Interference fits are commonly used in applications requiring permanent or semi-permanent assembly of mechanical components such as shafts and hubs, ensuring high load capacity and rotational stability. Typical uses include securing bearings, gears, and pulleys to shafts in automotive, aerospace, and heavy machinery industries. This type of fit provides excellent vibration resistance and precise alignment under heavy operational stresses.

Advantages and Disadvantages: Force Fit

Force fit provides a secure and robust mechanical connection by applying external force to assemble parts, ensuring high resistance to relative motion and vibration. Advantages include strong joint integrity and enhanced load transfer, while disadvantages involve potential damage to components from excessive assembly force and difficulty in disassembly or maintenance. This method is ideal for permanent or semi-permanent assemblies where contamination, loosening, or misalignment must be minimized.

Pros and Cons: Interference Fit

Interference fit offers superior strength and stability by creating a tight joint through material deformation, making it ideal for high-load applications and ensuring minimal relative movement between components. However, this fit requires precise machining and can cause stress concentrations, increasing the risk of component damage or deformation during assembly and disassembly. The difficulty in removing parts once fitted also leads to higher maintenance complexity and costs.

Choosing the Right Fit for Your Project

Choosing the right fit between force fit and interference fit depends on the specific application requirements such as load, material properties, and assembly methods. Force fit involves applying a controlled force to assemble parts with a tight tolerance, ideal for components that must resist moderate loads without permanent deformation. Interference fit creates a more permanent connection through slight dimensional oversizing, providing greater load transmission and resistance to movement, making it suitable for high-stress mechanical joints.

Conclusion: Selecting Between Force and Interference Fits

Selecting between force fit and interference fit depends on application requirements such as load capacity, assembly method, and precision. Force fits are ideal for parts requiring strong, permanent attachment with slight elastic deformation, while interference fits provide a tighter bond through controlled material overlap and expansion. Careful consideration of material properties, tolerance levels, and service conditions ensures optimal fit selection for mechanical performance and durability.

Force fit Infographic

libterm.com

libterm.com