Conduction is the process of heat transfer through direct contact between molecules, where energy is passed from one particle to another without the movement of the material itself. This phenomenon is essential in everyday activities like cooking and the functioning of electronic devices. Explore the rest of the article to understand how conduction impacts your daily life and its practical applications.

Table of Comparison

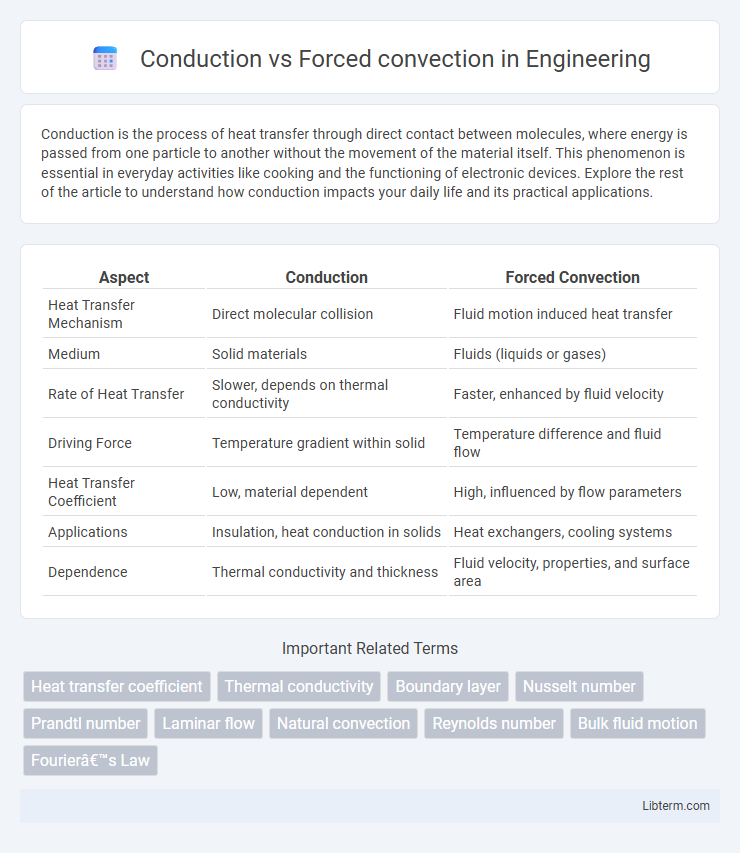

| Aspect | Conduction | Forced Convection |

|---|---|---|

| Heat Transfer Mechanism | Direct molecular collision | Fluid motion induced heat transfer |

| Medium | Solid materials | Fluids (liquids or gases) |

| Rate of Heat Transfer | Slower, depends on thermal conductivity | Faster, enhanced by fluid velocity |

| Driving Force | Temperature gradient within solid | Temperature difference and fluid flow |

| Heat Transfer Coefficient | Low, material dependent | High, influenced by flow parameters |

| Applications | Insulation, heat conduction in solids | Heat exchangers, cooling systems |

| Dependence | Thermal conductivity and thickness | Fluid velocity, properties, and surface area |

Introduction to Heat Transfer Mechanisms

Heat transfer mechanisms include conduction and forced convection, fundamental processes in thermal engineering. Conduction involves heat transfer through direct molecular interaction within a solid or stationary fluid, governed by Fourier's law. Forced convection enhances heat transfer by fluid motion driven by external forces such as fans or pumps, significantly increasing the convective heat transfer coefficient.

What is Conduction?

Conduction is the heat transfer process where thermal energy moves through a solid material due to molecular vibrations and electron movement without any bulk motion of the material itself. It occurs primarily in metals and solids, where atoms are tightly packed, allowing faster energy transfer compared to fluids. Understanding conduction is crucial for designing efficient thermal insulation and managing heat dissipation in electronic devices.

Fundamentals of Forced Convection

Forced convection involves the transfer of heat through a fluid induced by an external source such as a pump or fan, enhancing the heat transfer rate compared to natural convection. The heat transfer coefficient in forced convection depends on factors like fluid velocity, viscosity, thermal conductivity, and flow geometry, governed by the Reynolds and Nusselt numbers. Understanding the fundamentals requires analyzing fluid dynamics and thermal boundary layers to optimize heat exchanger performance and cooling systems.

Key Differences Between Conduction and Forced Convection

Conduction is the heat transfer process through direct molecular collision within a solid or stationary fluid, characterized by a temperature gradient and governed by Fourier's law. Forced convection involves the movement of fluid induced by external means such as fans or pumps, enhancing heat transfer by carrying thermal energy away from surfaces according to Newton's law of cooling. The key differences lie in conduction's reliance on molecular interactions without fluid motion, while forced convection depends on fluid flow velocity to increase the convective heat transfer coefficient and overall heat transfer rate.

Heat Transfer Equations: Conduction vs Forced Convection

Heat transfer by conduction is governed by Fourier's law, expressed as q = -kA(dT/dx), where q is the heat transfer rate, k is the thermal conductivity, A is the cross-sectional area, and dT/dx is the temperature gradient. In forced convection, the heat transfer rate follows Newton's law of cooling, q = hA(T_s - T_), where h is the convective heat transfer coefficient, A is the surface area, T_s is the surface temperature, and T_ is the fluid temperature far from the surface. The convective heat transfer coefficient h depends on fluid velocity, viscosity, thermal conductivity, and flow characteristics, contrasting with the material-dependent parameter k in conduction.

Factors Affecting Conduction and Forced Convection

Conduction heat transfer depends primarily on the thermal conductivity of the material, temperature gradient, and the cross-sectional area through which heat flows. Forced convection is influenced by fluid velocity, properties of the fluid such as viscosity and thermal conductivity, and the surface area in contact with the moving fluid. Surface roughness and flow regime, whether laminar or turbulent, also critically affect heat transfer rates in forced convection.

Real-World Applications of Conduction

Conduction is a primary heat transfer method in solid materials, extensively utilized in cooking utensils such as metal pans where heat moves directly through the material to cook food uniformly. It plays a crucial role in electronic devices by dissipating heat from components to heat sinks, preventing overheating and ensuring optimal performance. Industrial processes like metal forging and casting rely on conduction to transfer thermal energy efficiently within solid molds and materials for precise temperature control.

Practical Examples of Forced Convection

Forced convection occurs when an external force, such as a fan or pump, induces fluid motion to enhance heat transfer, commonly seen in cooling systems like computer fans and HVAC units. Examples include air forced over engine radiators to dissipate heat and liquid coolant circulated in car engines to prevent overheating. This mechanism significantly improves thermal efficiency compared to conduction, where heat transfer relies solely on molecular interactions without fluid movement.

Comparative Efficiency in Various Systems

Conduction transfers heat through direct molecular contact, making it highly efficient in solid materials with low thermal resistance, such as metals used in heat sinks. Forced convection enhances heat transfer by mechanically circulating fluid, significantly increasing efficiency in systems like HVAC and cooling of electronic devices where air or liquid movement reduces thermal boundary layers. Comparative efficiency favors forced convection in applications requiring rapid heat dissipation across fluid interfaces, while conduction prevails in compact, solid-state devices with minimal fluid interaction.

Summary: Choosing the Right Heat Transfer Method

Conduction involves direct heat transfer through a solid medium by molecular interaction, making it efficient for stationary or solid materials with high thermal conductivity. Forced convection enhances heat transfer by using external means like fans or pumps to move fluid, optimizing heat exchange in liquids and gases where conduction alone is insufficient. Selecting the right method depends on the material properties, temperature gradients, and application-specific factors such as fluid velocity and surface area.

Conduction Infographic

libterm.com

libterm.com