Lip seal technology ensures effective sealing by preventing fluid leakage and contamination in hydraulic and pneumatic systems. Maintaining a proper lip seal enhances the longevity and performance of your machinery by providing reliable resistance to pressure and wear. Discover how choosing the right lip seal can optimize your equipment's efficiency in the full article.

Table of Comparison

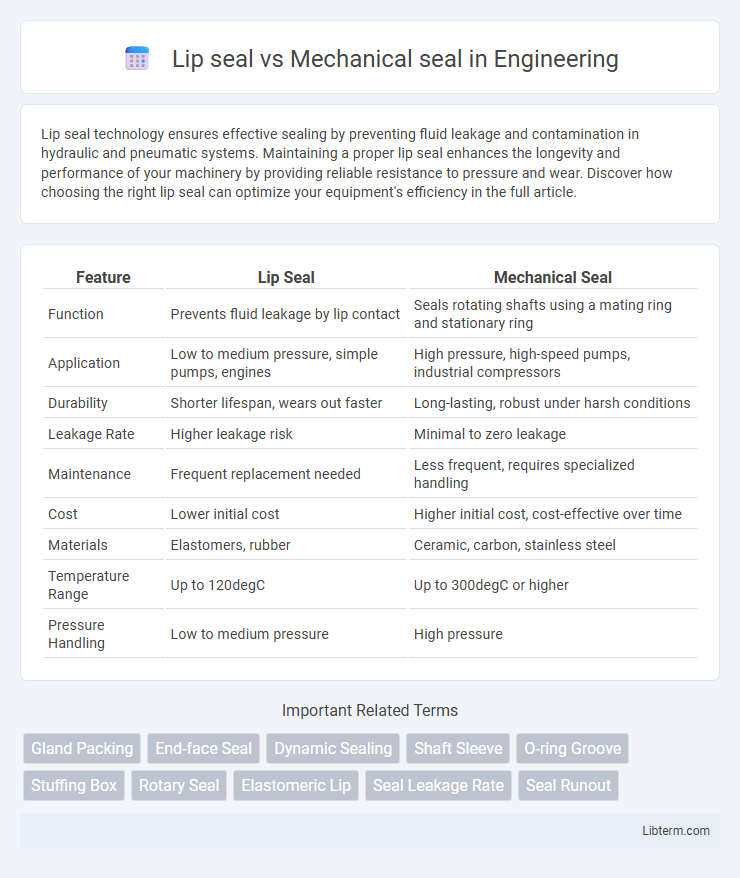

| Feature | Lip Seal | Mechanical Seal |

|---|---|---|

| Function | Prevents fluid leakage by lip contact | Seals rotating shafts using a mating ring and stationary ring |

| Application | Low to medium pressure, simple pumps, engines | High pressure, high-speed pumps, industrial compressors |

| Durability | Shorter lifespan, wears out faster | Long-lasting, robust under harsh conditions |

| Leakage Rate | Higher leakage risk | Minimal to zero leakage |

| Maintenance | Frequent replacement needed | Less frequent, requires specialized handling |

| Cost | Lower initial cost | Higher initial cost, cost-effective over time |

| Materials | Elastomers, rubber | Ceramic, carbon, stainless steel |

| Temperature Range | Up to 120degC | Up to 300degC or higher |

| Pressure Handling | Low to medium pressure | High pressure |

Introduction to Lip Seals and Mechanical Seals

Lip seals are flexible sealing components designed to prevent leakage in rotating or reciprocating shafts by maintaining contact with the shaft surface, commonly made from elastomeric materials for durability and chemical resistance. Mechanical seals consist of two flat surfaces, one stationary and one rotating, pressed together to create a seal that is highly effective in high-pressure and high-speed applications, often used in pumps and compressors. Both types of seals play critical roles in fluid containment, with lip seals favored for simpler, lower-pressure environments and mechanical seals preferred for demanding industrial conditions requiring enhanced reliability.

How Lip Seals Work

Lip seals work by creating a tight barrier between rotating shafts and stationary housings, relying on a flexible elastomeric lip that presses against the shaft surface to prevent fluid leakage. The lip is often spring-loaded to maintain consistent contact pressure, compensating for shaft misalignments and wear over time. This sealing mechanism efficiently blocks contaminants from entering while retaining lubricants within pumps, motors, and gearboxes.

How Mechanical Seals Work

Mechanical seals function by creating a sealing interface between the rotating shaft and stationary housing, using two flat, polished surfaces pressed together by a spring or other mechanical force to prevent fluid leakage. Unlike lip seals that rely on elastomer lips maintaining contact, mechanical seals utilize precisely engineered materials such as carbon, ceramic, or silicon carbide for durability and enhanced sealing performance. This design effectively controls fluid leakage under high pressure, temperature, and speed conditions, making mechanical seals essential in pumps and rotating equipment.

Key Differences Between Lip Seals and Mechanical Seals

Lip seals rely on a flexible lip made of elastomer to prevent fluid leakage by maintaining contact with a rotating shaft, making them ideal for low-pressure and low-speed applications. Mechanical seals utilize a combination of stationary and rotating components with a precisely machined sealing surface, offering superior leak prevention under high-pressure, high-speed, and harsh operating conditions. Key differences include the complexity, durability, pressure handling, and cost, with mechanical seals providing enhanced reliability and longevity in demanding industrial environments compared to the simpler design and cost-effective nature of lip seals.

Applications of Lip Seals

Lip seals are widely used in automotive and industrial machinery to prevent lubricant leakage and exclude contaminants from rotating shafts, ensuring optimal performance in engines, gearboxes, and pumps. Their flexible, non-metallic design makes them ideal for applications involving moderate speeds and temperatures, especially where cost-effectiveness and ease of installation are critical. Unlike mechanical seals, lip seals excel in sealing dynamic parts where slight shaft misalignment and axial motion occur, making them preferred in hydraulic systems and agricultural equipment.

Applications of Mechanical Seals

Mechanical seals are widely used in applications requiring high-pressure containment and aggressive chemical environments, such as pumps, compressors, and mixers in the chemical, petrochemical, and pharmaceutical industries. Their superior sealing capability prevents leakage in rotating equipment handling hazardous fluids, ensuring operational safety and reliability in critical industrial processes. Mechanical seals also enhance equipment longevity by reducing wear and maintenance frequency in high-speed and high-temperature settings.

Performance and Reliability Comparison

Lip seals provide effective sealing for low to moderate pressure applications with minimal friction and wear, offering reliable performance in dynamic environments. Mechanical seals, designed for high-pressure and high-speed operations, deliver superior leakage prevention and longer operational life through advanced sealing mechanisms. Overall, mechanical seals outperform lip seals in durability and sealing integrity, particularly in demanding industrial settings.

Cost Analysis: Lip Seal vs Mechanical Seal

Lip seals generally offer lower upfront costs and simpler installation compared to mechanical seals, making them cost-effective for less demanding applications. Mechanical seals, despite a higher initial investment, provide superior durability and reduced maintenance frequency, leading to lower long-term operational costs in high-pressure or high-speed environments. Evaluating total cost of ownership involves considering factors such as seal lifespan, replacement frequency, leakage risk, and associated downtime expenses.

Maintenance and Lifespan Considerations

Lip seals require regular inspection and replacement due to wear caused by friction and exposure to contaminants, often resulting in a shorter lifespan of 6 months to 2 years. Mechanical seals offer superior durability with lifespans ranging from 1 to 5 years or more, depending on operating conditions, and require periodic maintenance such as lubricant checks and seal face cleaning. Proper maintenance of mechanical seals reduces downtime and extends operational efficiency, while lip seals demand more frequent attention to prevent leaks and equipment damage.

Choosing the Right Seal for Your Application

Choosing the right seal for your application depends on factors such as operating pressure, temperature, and fluid compatibility. Lip seals are ideal for low-pressure and less demanding environments, providing effective sealing for rotary shafts with minimal leakage. Mechanical seals offer superior durability and performance in high-pressure, high-temperature, and chemically aggressive conditions, ensuring reliable sealing in pumps and compressors.

Lip seal Infographic

libterm.com

libterm.com