Binder jetting is an advanced additive manufacturing process that uses a liquid binding agent to join powder materials layer by layer, creating complex metal or ceramic parts without the need for high heat. This technique offers rapid production, design flexibility, and cost savings, making it ideal for prototyping and small batch manufacturing. Discover how binder jetting can transform your production workflow by reading the full article.

Table of Comparison

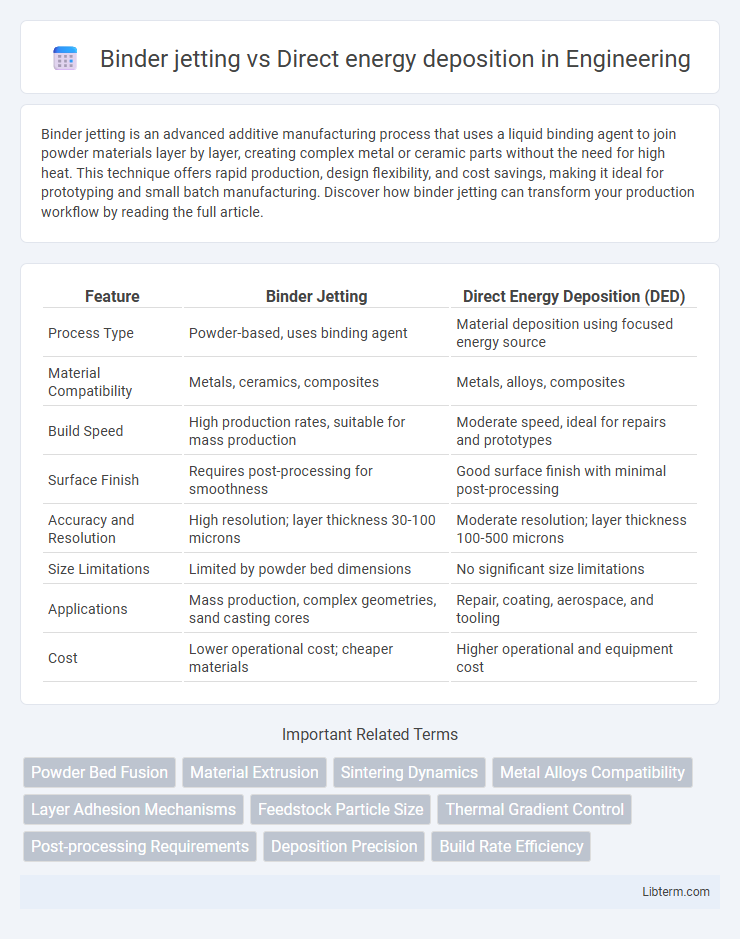

| Feature | Binder Jetting | Direct Energy Deposition (DED) |

|---|---|---|

| Process Type | Powder-based, uses binding agent | Material deposition using focused energy source |

| Material Compatibility | Metals, ceramics, composites | Metals, alloys, composites |

| Build Speed | High production rates, suitable for mass production | Moderate speed, ideal for repairs and prototypes |

| Surface Finish | Requires post-processing for smoothness | Good surface finish with minimal post-processing |

| Accuracy and Resolution | High resolution; layer thickness 30-100 microns | Moderate resolution; layer thickness 100-500 microns |

| Size Limitations | Limited by powder bed dimensions | No significant size limitations |

| Applications | Mass production, complex geometries, sand casting cores | Repair, coating, aerospace, and tooling |

| Cost | Lower operational cost; cheaper materials | Higher operational and equipment cost |

Overview of Binder Jetting and Direct Energy Deposition

Binder Jetting uses a liquid binding agent to selectively adhere powdered material layer-by-layer, enabling rapid production of complex metal, ceramic, or sand parts without high-temperature melting. Direct Energy Deposition (DED) employs focused energy sources such as lasers or electron beams to melt material feedstock (powder or wire) as it is deposited, allowing precise repair, coating, or fabrication with metallurgical bonding. Both methods offer unique advantages in additive manufacturing, with Binder Jetting excelling in speed and scalability, while DED provides superior part strength and versatility in material choices.

How Binder Jetting Works

Binder jetting creates 3D objects by selectively depositing a liquid binding agent onto a thin layer of powdered material, bonding particles together before a new layer of powder is spread on top. This layer-by-layer approach repeats until the full structure is formed, followed by curing or sintering to enhance strength and durability. Unlike direct energy deposition, which uses focused energy sources to melt material during the process, binder jetting operates at room temperature and relies on post-processing to achieve final part properties.

How Direct Energy Deposition Works

Direct Energy Deposition (DED) employs focused thermal energy, such as laser, electron beam, or plasma arc, to melt metallic powders or wires as they are simultaneously deposited layer-by-layer onto a substrate, enabling precise material addition and repair. This additive manufacturing process allows for creating complex geometries and hybrid structures by directly fusing material without the need for molds or supports. DED's ability to tailor deposition parameters in real-time facilitates enhanced mechanical properties and metallurgical control compared to Binder Jetting, which binds powder particles with adhesives before sintering.

Key Differences Between Binder Jetting and DED

Binder Jetting uses a liquid binding agent to fuse powder particles layer-by-layer, enabling high-speed production of complex geometries with minimal residual stress. Direct Energy Deposition (DED) employs focused thermal energy such as a laser or electron beam to melt and fuse material directly onto a substrate, allowing for repair applications and the fabrication of large components with superior mechanical properties. Binder Jetting is generally faster but requires post-processing sintering, whereas DED offers superior material density and metallurgical bonding without extensive secondary treatments.

Material Compatibility in Binder Jetting vs DED

Binder jetting excels in material compatibility by enabling a wide range of metals, ceramics, and composites to be processed without thermal distortion, as it operates at room temperature prior to sintering. Direct energy deposition (DED) uses focused energy sources such as lasers or electron beams to melt materials during deposition, which limits its compatibility primarily to metals and alloys that can withstand high thermal stresses. Binder jetting's ability to process brittle and complex materials without melting provides a broader material selection compared to the high-temperature constraints inherent in DED.

Surface Finish and Part Accuracy Comparison

Binder jetting provides smoother surface finishes due to its layer-by-layer powder deposition and curing process, resulting in lower surface roughness compared to Direct Energy Deposition (DED). Part accuracy in binder jetting is typically higher, with finer details achievable thanks to precise binder application, whereas DED often produces parts with coarser surfaces and requires additional machining to meet tight tolerances. The thermal input in DED can cause microstructural changes and dimensional distortions, negatively impacting part accuracy compared to the relatively low-temperature process of binder jetting.

Speed and Efficiency: Which Process is Faster?

Binder jetting offers faster build speeds by rapidly depositing binder onto powder layers without melting, enabling high throughput in large-scale parts production. Direct energy deposition involves melting feedstock material with a focused energy source, which generally results in slower build rates due to the precision and energy required for layer fusion. For applications prioritizing speed and efficiency, binder jetting typically outperforms direct energy deposition in terms of faster printing time and scalability.

Cost Effectiveness in Binder Jetting vs DED

Binder jetting offers superior cost-effectiveness compared to direct energy deposition (DED) due to lower equipment and operation expenses, alongside its ability to produce parts at higher speeds without the need for support structures. The powder-based process in binder jetting utilizes cheaper materials and reduces energy consumption, significantly lowering production costs relative to the high-energy lasers and complex feedstock systems required in DED. These factors make binder jetting particularly advantageous for large-scale manufacturing and low to medium-complexity metal parts where cost efficiency is critical.

Typical Applications of Binder Jetting and DED

Binder jetting excels in producing complex metal and ceramic parts for aerospace, automotive, and medical industries, often used for prototype development, custom tooling, and small-batch production. Direct energy deposition (DED) is typically applied in repair and refurbishment of high-value components, such as turbine blades and aerospace parts, as well as in manufacturing large metal structures and adding features to existing parts. Both methods support additive manufacturing but serve distinct purposes based on precision, material compatibility, and scale of production.

Choosing the Right Technology for Your Project

Binder jetting offers high-speed production and cost-efficiency for complex geometries using powdered materials, ideal for large-scale manufacturing and intricate parts without thermal distortion. Direct energy deposition excels in repair and adding features to existing components, leveraging a focused energy source like laser or electron beam to melt and fuse material with excellent metallurgical bonding. Selecting the right technology depends on project goals such as production volume, material compatibility, part complexity, and precision requirements.

Binder jetting Infographic

libterm.com

libterm.com