Shear cutting is a precise metalworking process that involves applying a force to cut materials along a straight line, resulting in smooth, clean edges. This technique is commonly used for sheet metal fabrication, enabling efficient and accurate shaping with minimal material waste. Discover how shear cutting can enhance Your manufacturing projects by exploring the full article.

Table of Comparison

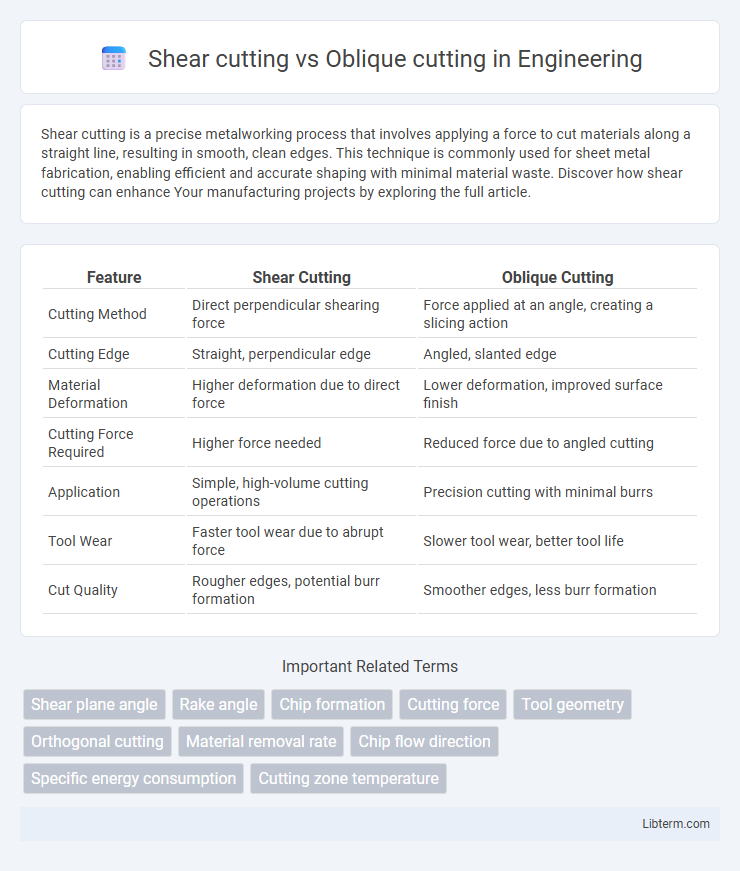

| Feature | Shear Cutting | Oblique Cutting |

|---|---|---|

| Cutting Method | Direct perpendicular shearing force | Force applied at an angle, creating a slicing action |

| Cutting Edge | Straight, perpendicular edge | Angled, slanted edge |

| Material Deformation | Higher deformation due to direct force | Lower deformation, improved surface finish |

| Cutting Force Required | Higher force needed | Reduced force due to angled cutting |

| Application | Simple, high-volume cutting operations | Precision cutting with minimal burrs |

| Tool Wear | Faster tool wear due to abrupt force | Slower tool wear, better tool life |

| Cut Quality | Rougher edges, potential burr formation | Smoother edges, less burr formation |

Introduction to Shear and Oblique Cutting

Shear cutting uses two blades moving past each other in a scissor-like motion to create clean, precise cuts typically on sheet metal. Oblique cutting involves angled blades that slice material with a slight sliding action, reducing cutting force and producing smoother edges on tougher materials. Both methods are essential in manufacturing for optimizing cut quality and minimizing material deformation.

Fundamentals of Shear Cutting

Shear cutting involves applying a straight, linear force to slice through a material, relying on stress concentration at the cutting edge to initiate fracture. The fundamental principle is the generation of shear stress that exceeds the material's shear strength, producing a clean and precise cut, typically used in metal sheet processing. Unlike oblique cutting, which uses angled forces to reduce cutting resistance and improve surface finish, shear cutting emphasizes uniform, perpendicular force application for efficient separation of materials.

Principles of Oblique Cutting

Oblique cutting involves a cutting tool edge that is inclined to the direction of tool travel, causing a shear plane to form at an angle which reduces the cutting force and heat generation. This technique improves chip flow by directing chips away from the cutting zone, resulting in smoother surface finish and extended tool life compared to shear cutting. The principal advantage of oblique cutting lies in the angled shear deformation, which enhances efficiency in metal machining processes such as turning and milling.

Key Differences Between Shear and Oblique Cutting

Shear cutting involves a straight, perpendicular cut through material using shear forces, resulting in minimal deformation and clean edges, commonly used in sheet metal processing. Oblique cutting employs an angled cutting edge that shears material progressively, leading to reduced cutting forces and improved surface finish due to a slicing action. Key differences include the cutting angle--90 degrees in shear versus an acute angle in oblique--and the resulting force distribution, chip formation, and surface quality, influencing tool wear and energy consumption.

Advantages of Shear Cutting

Shear cutting offers precise and clean cuts with minimal burr formation, making it ideal for finishing and reducing post-processing work. The process ensures high dimensional accuracy and maintains material integrity by applying a straight shear force, which decreases distortion and waste. Compared to oblique cutting, shear cutting provides faster cycle times and improved edge quality, enhancing overall manufacturing efficiency.

Benefits of Oblique Cutting

Oblique cutting offers improved surface finish and reduced cutting forces compared to shear cutting, resulting in less tool wear and extended tool life. The angled cutting edge in oblique cutting helps distribute the cutting load more evenly, leading to better dimensional accuracy and finer chip formation. This process enhances machinability of hard materials and supports higher cutting speeds, increasing overall manufacturing efficiency.

Limitations and Challenges of Each Method

Shear cutting faces limitations such as excessive burr formation and high tool wear when processing hard or thick materials, which reduces precision and tool longevity. Oblique cutting challenges include increased friction and heat generation at the cutting interface, leading to faster tool degradation and potential surface damage on sensitive materials. Both methods require careful selection of cutting parameters to mitigate these issues and ensure optimal performance across different material types.

Applications in Manufacturing and Engineering

Shear cutting is predominantly used in sheet metal fabrication, offering precise, straight cuts ideal for producing components like automotive panels and appliance parts. Oblique cutting excels in machining complex geometries with reduced cutting force, making it suitable for aerospace components and precision engineering parts where surface finish and dimensional accuracy are critical. Both techniques enhance manufacturing efficiency by optimizing material removal methods for specific engineering applications.

Factors Influencing Cutting Method Selection

Material thickness, hardness, and the desired edge quality are critical factors influencing the selection between shear cutting and oblique cutting methods. Shear cutting is preferred for thinner, softer materials requiring clean edges, while oblique cutting suits thicker, tougher materials needing reduced cutting forces. Tool geometry and machine capabilities also play a significant role in determining the optimal cutting technique for efficiency and precision.

Conclusion: Choosing the Right Cutting Technique

Selecting between shear cutting and oblique cutting depends on material properties and desired edge quality; shear cutting typically offers cleaner cuts with less deformation for thin metals, while oblique cutting is preferred for thicker or harder materials due to reduced cutting forces and extended tool life. Shear cutting minimizes burr formation and is ideal for precision applications, whereas oblique cutting enhances efficiency in heavy-duty industrial processes. Understanding these distinctions ensures optimal machining performance, lower operational costs, and improved product quality.

Shear cutting Infographic

libterm.com

libterm.com