A Hazard and Operability Study (HAZOP) systematically identifies potential hazards and operational issues in industrial processes to enhance safety and efficiency. This method uses structured brainstorming techniques to pinpoint deviations from design intentions and assess their possible impacts. Explore the rest of the article to understand how HAZOP can protect your facility and optimize operations.

Table of Comparison

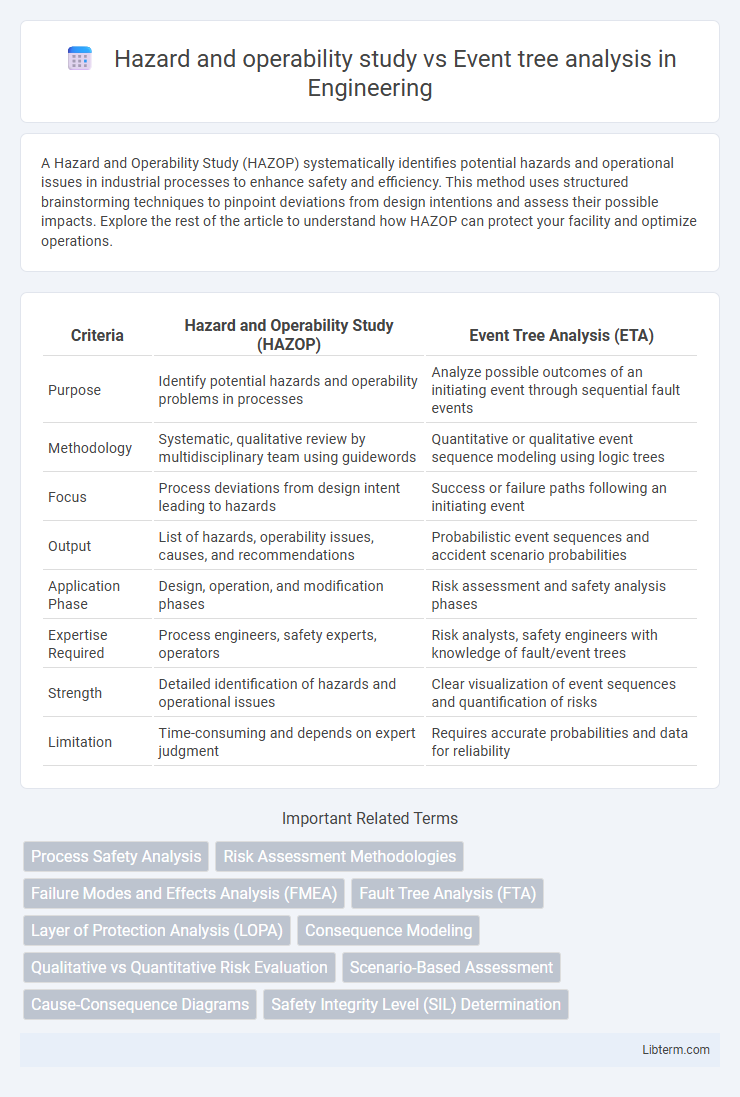

| Criteria | Hazard and Operability Study (HAZOP) | Event Tree Analysis (ETA) |

|---|---|---|

| Purpose | Identify potential hazards and operability problems in processes | Analyze possible outcomes of an initiating event through sequential fault events |

| Methodology | Systematic, qualitative review by multidisciplinary team using guidewords | Quantitative or qualitative event sequence modeling using logic trees |

| Focus | Process deviations from design intent leading to hazards | Success or failure paths following an initiating event |

| Output | List of hazards, operability issues, causes, and recommendations | Probabilistic event sequences and accident scenario probabilities |

| Application Phase | Design, operation, and modification phases | Risk assessment and safety analysis phases |

| Expertise Required | Process engineers, safety experts, operators | Risk analysts, safety engineers with knowledge of fault/event trees |

| Strength | Detailed identification of hazards and operational issues | Clear visualization of event sequences and quantification of risks |

| Limitation | Time-consuming and depends on expert judgment | Requires accurate probabilities and data for reliability |

Introduction to Hazard and Operability Study (HAZOP) and Event Tree Analysis (ETA)

Hazard and Operability Study (HAZOP) systematically identifies potential hazards and operational issues by analyzing deviations from design intentions in complex processes, emphasizing team-based qualitative evaluation. Event Tree Analysis (ETA) quantitatively models possible accident scenarios by mapping forward from an initiating event through success or failure of safety barriers, enabling probabilistic risk assessment. Both HAZOP and ETA are essential tools in process safety management, with HAZOP focusing on hazard identification and ETA on consequence analysis and failure propagation.

Defining HAZOP: Purpose and Process

Hazard and Operability Study (HAZOP) is a systematic qualitative technique designed to identify potential hazards and operability problems in industrial processes by analyzing deviations from design intentions using guide words. The purpose of HAZOP is to enhance safety and reliability by examining process parameters through structured team-based brainstorming sessions to detect risks early. The process involves defining the scope, selecting nodes, applying guide words to identify deviations, and recommending actions to mitigate identified hazards.

Event Tree Analysis: Scope and Methodology

Event Tree Analysis (ETA) systematically evaluates the progression of events following an initiating incident to predict possible outcomes and quantify associated risks. Its scope includes modeling complex systems' failure paths by constructing branching sequences that represent event consequences, aiding in decision-making for safety measures. ETA methodology involves identifying initiating events, defining subsequent event sequences using logical gates, and calculating probabilities to assess hazardous event likelihoods comprehensively.

Key Differences Between HAZOP and ETA

Hazard and Operability Study (HAZOP) primarily identifies potential hazards and operability issues using guide words to systematically examine deviations in process parameters, while Event Tree Analysis (ETA) focuses on analyzing the possible outcomes and sequences following an initiating event to assess system reliability and safety. HAZOP is qualitative and conducted during process design or modification phases, emphasizing cause-effect relationships in process deviations, whereas ETA is quantitative or semi-quantitative, employing probabilistic models to evaluate the likelihood of different accident scenarios and their consequences. HAZOP's strength lies in hazard identification through structured brainstorming, while ETA excels in consequence analysis by mapping event sequences and assessing their probability.

Comparative Objectives of HAZOP and ETA

Hazard and Operability Study (HAZOP) primarily aims to identify potential hazards and operability problems in process design by systematically examining deviations from design intent. Event Tree Analysis (ETA) focuses on the sequenced consequences following an initiating event, evaluating the probability of different outcomes to support risk assessment. While HAZOP emphasizes qualitative identification of hazards, ETA provides a quantitative framework for analyzing accident scenarios and their probabilities.

Applications of HAZOP in Process Safety

Hazard and Operability Study (HAZOP) is extensively applied in process safety to systematically identify potential deviations in chemical, petrochemical, and manufacturing processes that could lead to hazards or operational issues. It enhances risk management by analyzing design intentions against possible failures in equipment, control systems, and human actions, ensuring early detection of hazards and process deviations. Event Tree Analysis (ETA), by contrast, primarily evaluates the consequences of initiating events, but HAZOP remains superior in process industries for proactive identification of risks and operability problems during design and modification phases.

Common Uses of Event Tree Analysis in Risk Assessment

Event Tree Analysis (ETA) is commonly used in risk assessment to systematically evaluate the possible outcomes following an initiating event, helping to identify safety barriers and quantify the probability of various accident scenarios. It is particularly effective for modeling complex sequences of failures and their consequences in industries such as nuclear power, chemical processing, and aerospace, where understanding the progression from an initial fault to potential disasters is critical. Hazard and Operability Study (HAZOP), while focused on identifying deviations in process parameters, complements ETA by providing detailed insights into potential hazards, making ETA a preferred tool for probabilistic risk estimation and decision-making in safety management.

Strengths and Limitations of HAZOP vs Event Tree Analysis

HAZOP excels in identifying potential hazards through systematic examination of process deviations, making it highly effective for complex chemical processes, but it can be time-consuming and requires expert knowledge. Event Tree Analysis provides a clear, visual representation of possible event sequences and outcomes, facilitating risk quantification and decision-making, though it may oversimplify complex interactions and relies heavily on accurate probability data. Both methods complement each other, with HAZOP emphasizing qualitative hazard identification and Event Tree Analysis focusing on quantitative consequence evaluation.

Selecting the Right Method: HAZOP or ETA?

Selecting the right method between Hazard and Operability Study (HAZOP) and Event Tree Analysis (ETA) depends on the project's focus and complexity; HAZOP excels in identifying potential deviations in process design and operational stages, making it ideal for detailed risk assessments in chemical and industrial systems. Event Tree Analysis is more suitable for probabilistic evaluation of accident sequences, emphasizing the likelihood and consequences of initiating events and safety barriers. Choosing between HAZOP and ETA hinges on whether the goal is qualitative identification of hazards and operability issues or quantitative analysis of event probability and failure pathways.

Integrating HAZOP and ETA for Comprehensive Risk Management

Integrating Hazard and Operability Study (HAZOP) with Event Tree Analysis (ETA) enhances comprehensive risk management by combining qualitative identification of potential hazards with quantitative evaluation of event sequences and outcomes. HAZOP systematically identifies deviations in process parameters, while ETA models the probability of various failure paths and their consequences, enabling proactive mitigation strategies. This integrated approach improves hazard detection accuracy and supports decision-making through detailed risk estimation and scenario analysis.

Hazard and operability study Infographic

libterm.com

libterm.com